26

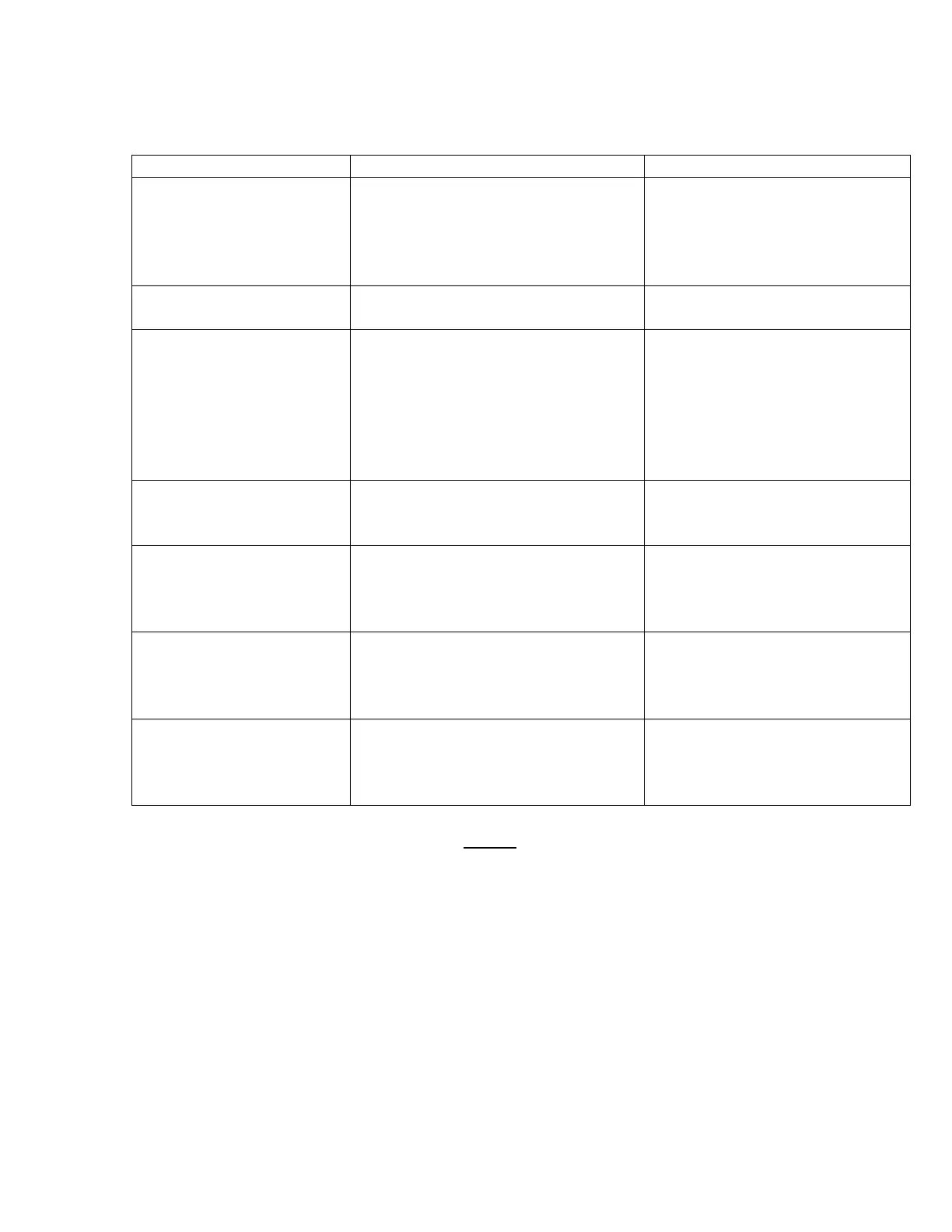

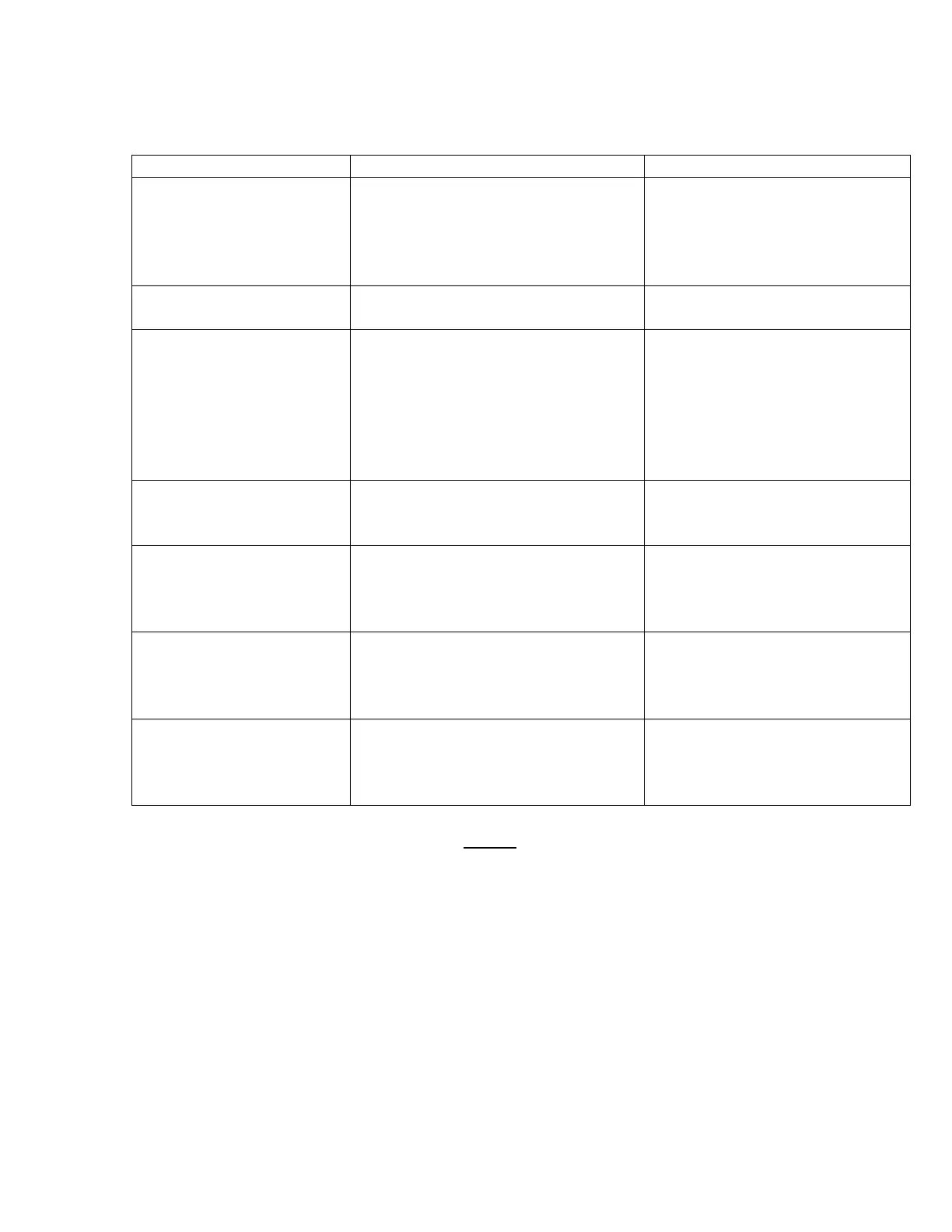

Section 4 Troubleshooting Chart

Problem Cause Remedy

Motors do not start 1. No power to unit

2. Vibration switch not reset

3. Limit switch on G.S. Coupling

tripped

1. Restore power

2. Reset vibration switch

Section 1.3.1

3. Reset limit switch

Section 1.3.1

Startup and shutdown

vibration

1. Moderate vibration at critical

rpm during startup and shutdown

1. None required

Machine vibrates 1. Bowl may be out of balance due

to poor cleaning, bowl parts

interchanged with another bowl

or uneven wear on conveyor or

bowl.

2. Vibration damping mounts have

lost elasticity.

1. Determine if vibration is

due to the causes described.

2. Replace rubber mounts.

Fluid coupling plug melts 1. Excessive amount of solids

causing overloading

2. Fluid volume or type wrong.

1. Reduce feed rate

2. Check oil level in coupling

3. Replace oil if in doubt

Noise from gearbox 1. Oil volume low or type wrong

2. Worn gears

3. Worn bearings

1. Check oil level and oil

type, replace if in doubt

2. Replace gearbox

3. Replace bearings

Continued disengagement

of G.S. Coupling

1. Large accumulation of solids in

bowl.

2. Excessive amount of solids in

feed mud.

1. Flush bowl

2. Reduce feed rate

Solids discharge too wet 1. Feed rate too high

2. Conveyor differential too high

1. Decrease feed rate

2. Change back drive motor

sheave to reduce differential

See Diagram 1

NOTE

THE ABOVE DESCRIBED ITEMS ARE NOT TO BE CONSIDERED CONCLUSIVE. IF

YOU HAVE ANY QUESTIONS, CONTACT SWACO ENGINEERING, HOUSTON,

TEXAS, 281-988-1868

Loading...

Loading...