63

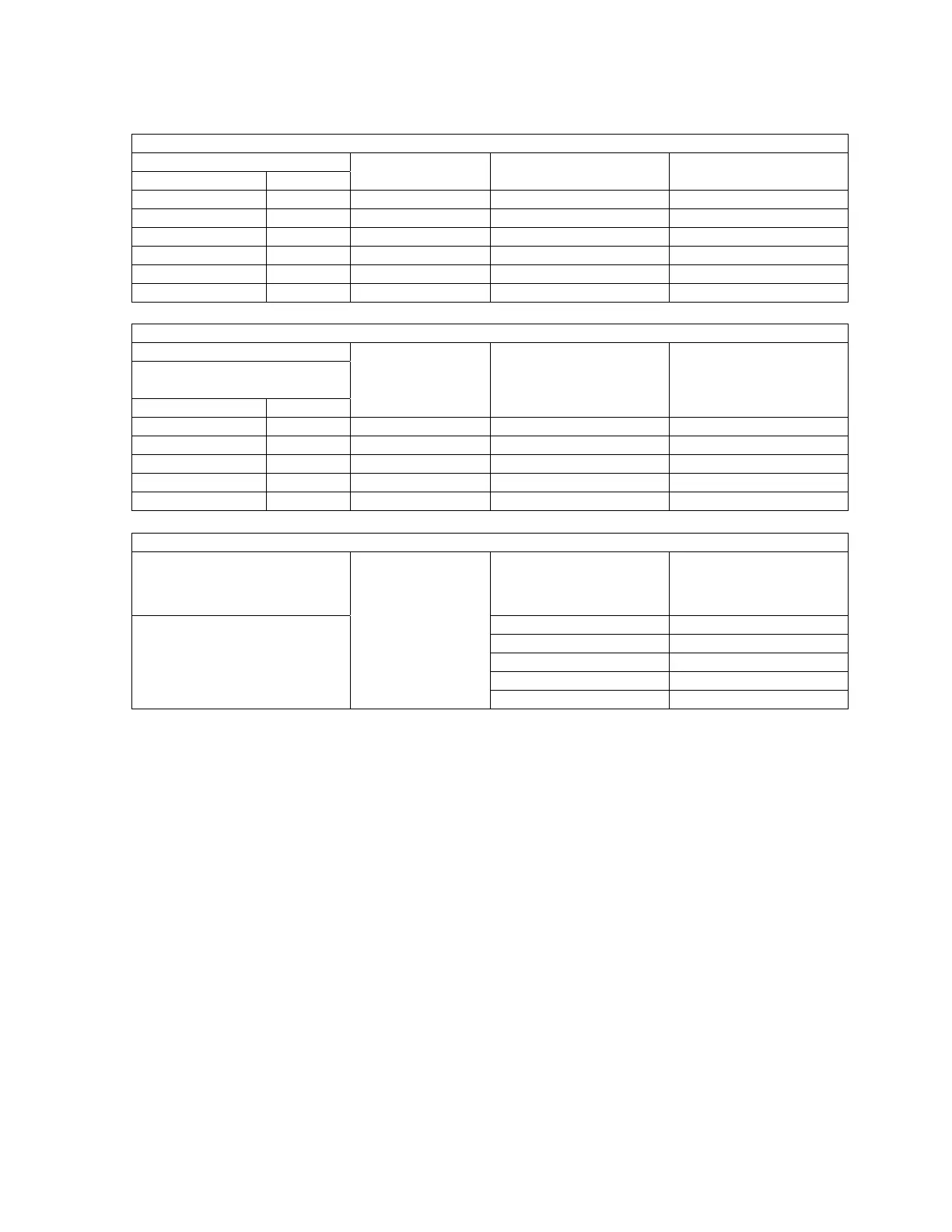

Table 1

Difference

(a-b) mm In.

Qty. Part No. Tmm

11.0-11.9 .43-.47 0

12.0-12.9 .47-.51 1 96-10-418 1

13.0-13.9 .51-.55 1 96-10-421 2

14.0-14.9 .55-.59 1 96-10-418

1 96-10-421 3

15.0-15.9 .59-.63 2 96-10-422 4

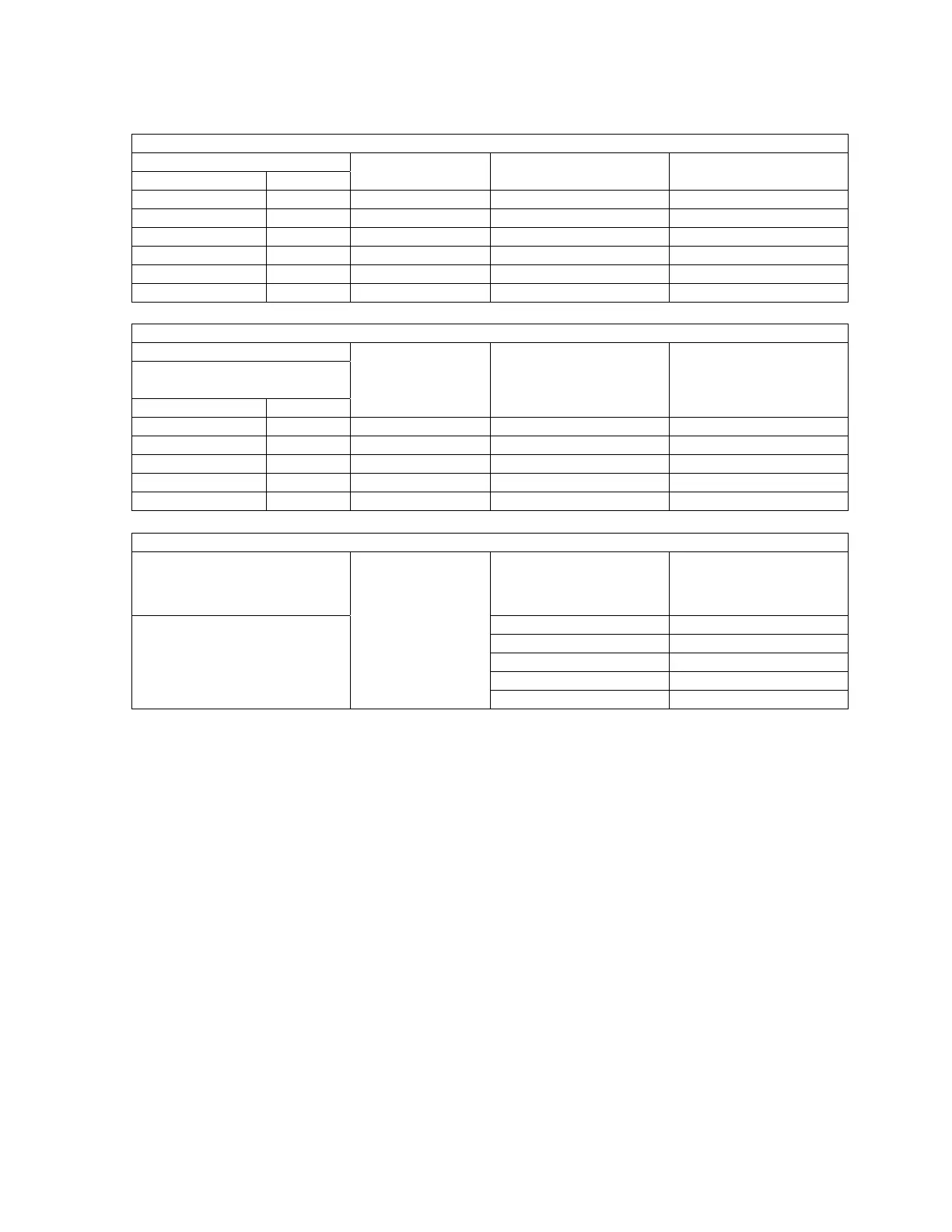

Table 2

Difference

(9.4 + d)-e mm

(.370 + d)-e In.

Mm In.

Qty. Part No. Tmm

0-0.4 0-.016 1 96-10-419 1

0.5-0.9 .02-.035 1 96-10-420 1.5

1.0-1.4 .04-.06 2 96-10-419 2

1 96-10-419

1.5-1.9 .06-.075 1 96-10-420 2.5

Table 3 Shim Thickness

Gearbox end of conveyor Part No. Tmm

96-10-418 1

96-10-421 1.5

2

96-10-419

Feed End of Conveyor

96-10-420 2.5

Adjustment of space between conical part of bowl and conveyor and axial clearance between

bowl and conveyor.

1. In addition to normal procedure when changing conveyor, remove the small end

piece.

2. Place the conveyor in the bowl shell so that it touches the cone.

3. Measure the distances a,b,d and e as shown in Diagram 9.

4. Calculate the difference a-b and find in Table 1 the adjusting shim or shims to be

placed at position T between the conveyor big end bore and the bearing arrangement

to give the right space.

5. Calculate the difference (9.4 + d) - e mm and find in Table 2 the adjusting shim or

shims to be placed at position (t) between the conveyor small end bore and the

bearing arrangement to give the right axial space between conveyor and bowl.

Diagram 9 (414 Centrifuge Method for determing adjusting shims)

Loading...

Loading...