78

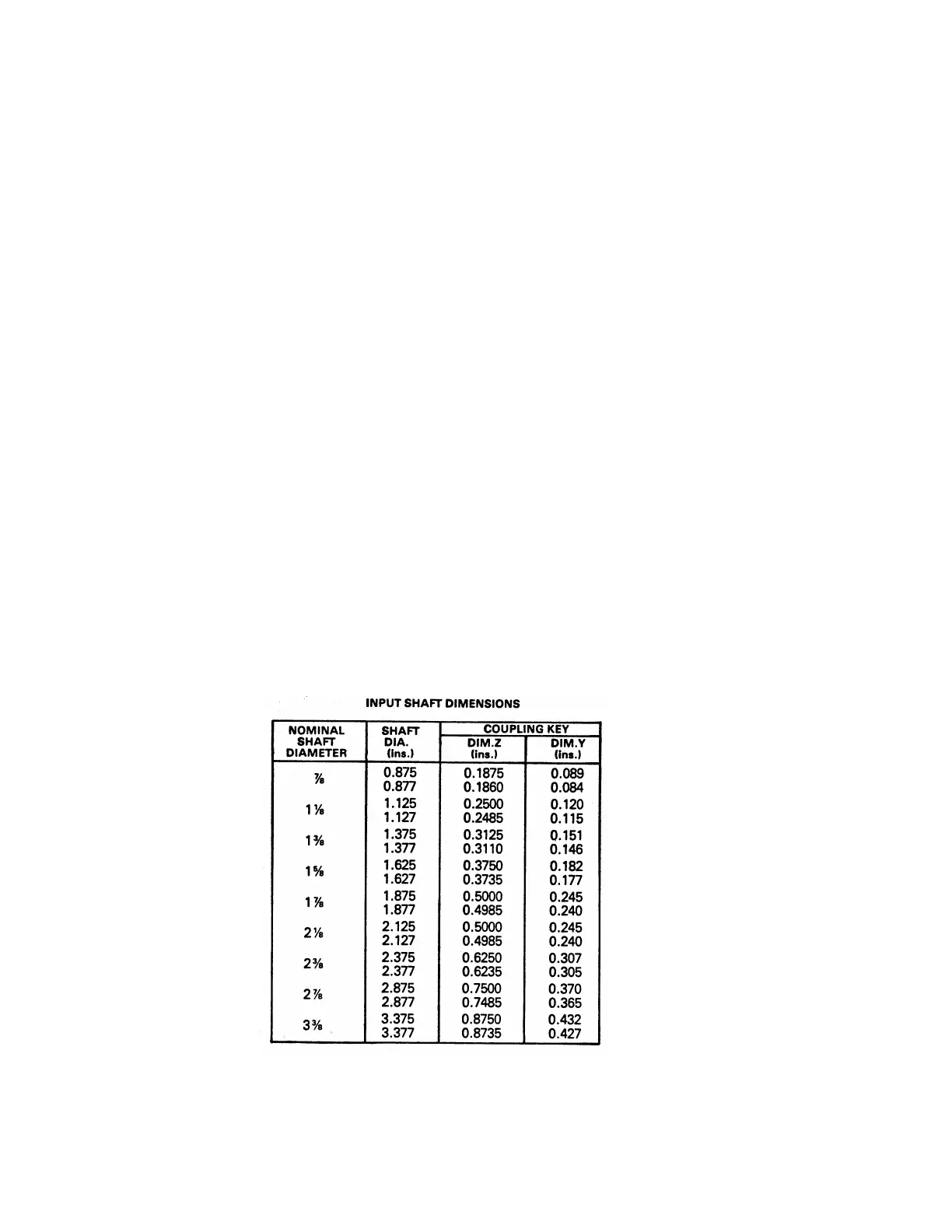

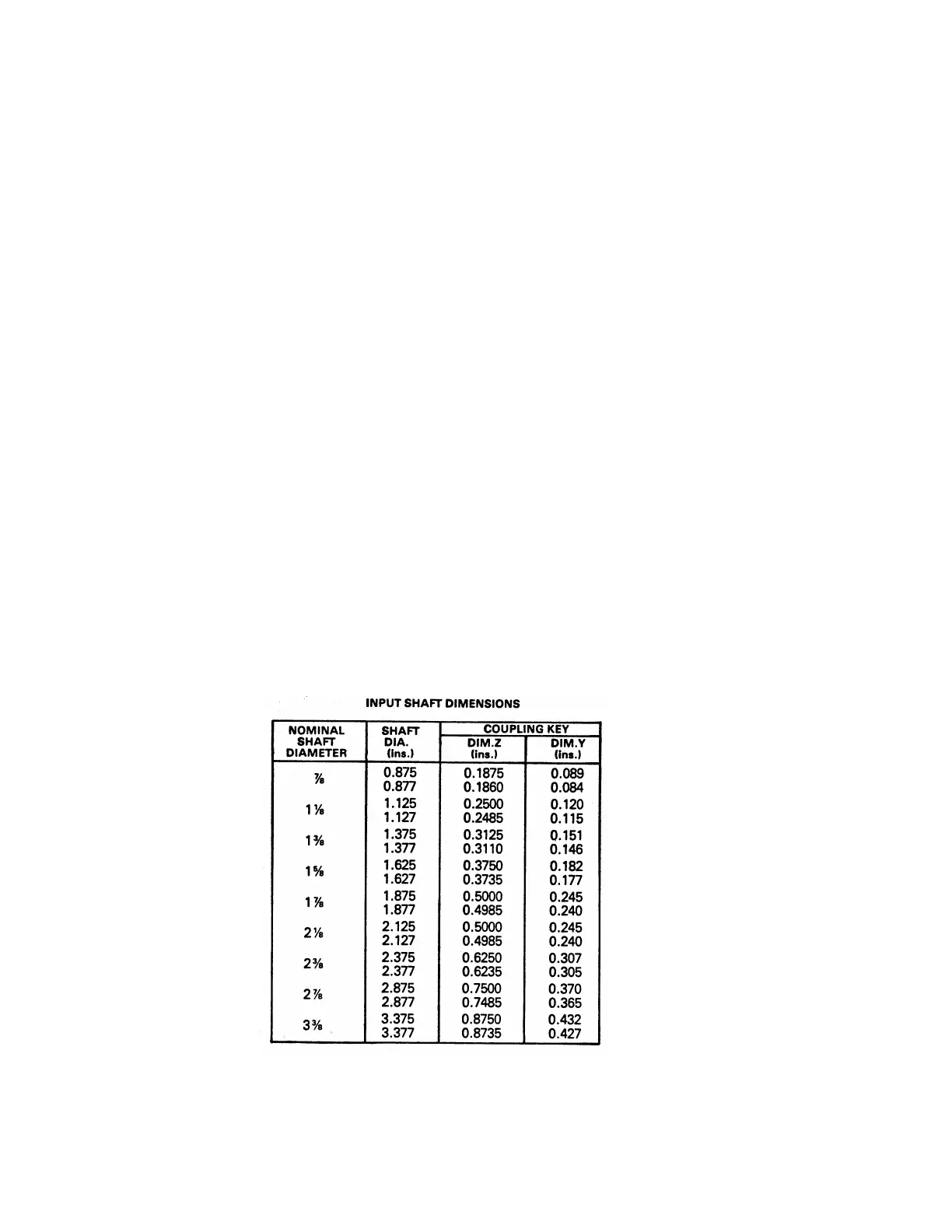

5. Fit the stepped key supplied into the motor shaft and mount the fluid coupling

on the motor shaft, ensuring that the key and shaft key are correctly aligned.

6. Move the coupling along the motor shaft as far as it will go. First tighten the

lone set screw opposite the key on to the motor shaft, then tighten the two

short set screws alternately to close input shaft evenly on to the motor shaft.

General Dismantling/Assembly Notes

1. Dismantle and assemble the Fluid Drive Coupling in a clean, dry area. Use

lint-free rags for cleaning.

2. Before assembly, ensure that all parts are clean and serviceable. Lubricate all

mating surfaces, screws, shafts and shaft hub tapers with oil free from

Molybdenum Disulfide.

3. If the fluid coupling is installed, ensure that the motor is correctly

disconnected from the power source before removing the coupling for

dismantling.

4. Loosen the three set screws in collar and withdraw fluid coupling from motor

shaft.

5. Use a suitable container when draining oil from the coupling.

6. For those units not using lockwashers, apply Loctite 242 or equivalent

anerobic locking adhesive to the bolt threads or the tappered hole after

cleaning with industrial solvent. Tighten all bolts to the torque valves given in

the installation instructions or torque table.

7. Always fit new gaskets and oil seals when reassembling the unit.

Loading...

Loading...