-12--11-

5.ELECTRONIC COMPONENTS

Operation step

Picture

1. Self-test method of wash

timer and

Turn the wash timer to work

condition. Use a multimeter to

measure the connection and

disconnection condition of

input terminal(brown wire) and

output terminal (yellow or orange

wire), and the wash timer should

be regular on-off.

wash-drain

selection switch

Use a mulimeter to measure the

selection switch, the switch

should be regular on-off.

5.ELECTRONIC COMPONENTS

2. Self-test method of capacitor

Use an analog multimeter to measure

capacitance by connecting the two

ends of capacitor with the multimeter

rod connector . If the pointer swing

to the direction of smaller

resistance ,and then turn back to

the direction of “0” slowly, it means

that the capacitor is ok. If not, it

means that the capacitor is

faulted.

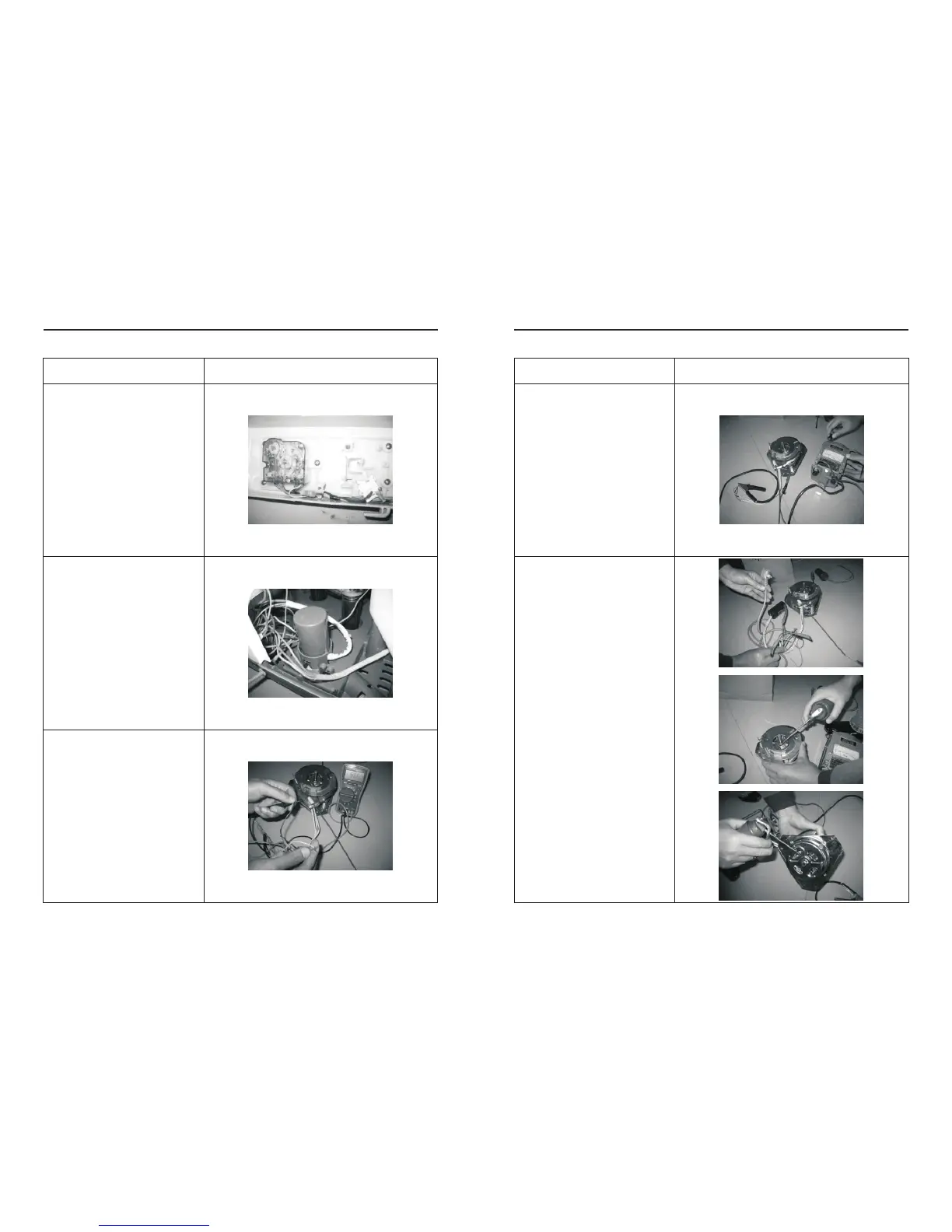

3. Self-test method of motor

a. To check whether the m oto r

in sulation is damaged by

wa ter l eakage:

Use a 500 V megohmmeter to

measure whether the insulation

resistance of motor is higher than

30MΩ At the same time, check

whether the other resistance of

the motor are normal. If the

other resistance are abnormal

(any short-circuit, open circuit

appears),the motor can not be

used. Only the two items are

normal, the motor can be used.

.

Operation step

Picture

b. Check whether the motor

resistance is normal in the

condition of no water

condition:

Use a multimeter to measure the

resistance of the three leads, and

name them R1, R2, R3

.Only the

“R1+R2=R3” indicates that the

motor resistance is normal.

(the max.

one name R3)

c. Check the motor operation

condition:

For the motor under

use, add certain 20 # machine oil on

the upper and down bearing to

eliminate the negative effect arising

from water leakage.After powering

on the two components, there

should be no obvious noise,

vibration,or odor of the motor.

Use power cable with fuse to

connect the motor and capacitor

correctly, and do the preparation

for insulation.

Loading...

Loading...