7

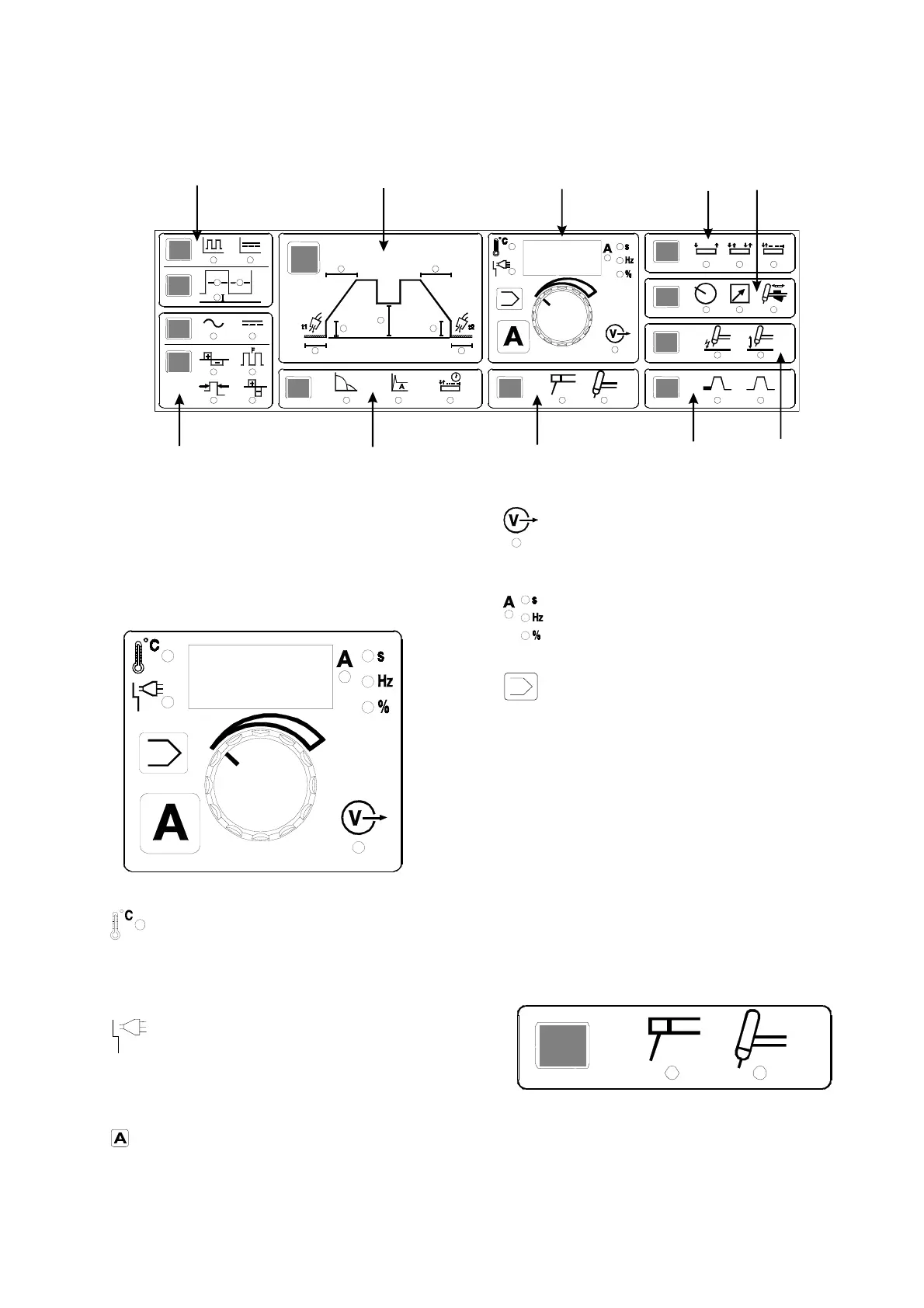

FUNCTION SELECTION AND

PARAMETER SETTING

This chapter describes the operation of the machine

in detail and includes references to the three different

control panels illustrated at the end of the chapter.

A

Overheating

The overheating indicator is illuminated if

welding is interrupted due to overheating of the ma-

chine. The indicator remains illuminated 3 seconds

after the overheating error is removed.

Mains error

The mains error indicator is illuminated if the

mains voltage is too high or low. The indicator

remains illuminated 3 seconds after the mains error is

corrected/removed.

On pressing this keypad the control knob can be

used to set the welding current.

Welding voltage

The welding voltage indicator is illuminated for

reasons of safety and in order to show if there is

voltage on the electrode or the TIG torch.

Units of measurement of the parameter

shown in the digital display.

Setting of welding jobs

This function enables storage of often-used

machine settings and shift from one complete setting

to another. By pressing the keypad the display shows

a "P" and a number: "1", "2" etc. Each number is a

setting of all parameters and functions of the

machine. It is therefore possible to have one setting

for each welding job for which the machine is used.

The control knob is used for shifting between these

settings. During shifting it is possible to see both pro-

cess and the other on/off-functions in each setting.

Change of setting is not possible during the welding

process. The setting selected is effected by releasing

the keypad.

B

Welding process

Electrode TIG

This display is used to select the welding process to

be used, e.g. MMA electrode or TIG.

H

G

A

C

D

EFBI

J

Loading...

Loading...