8

C

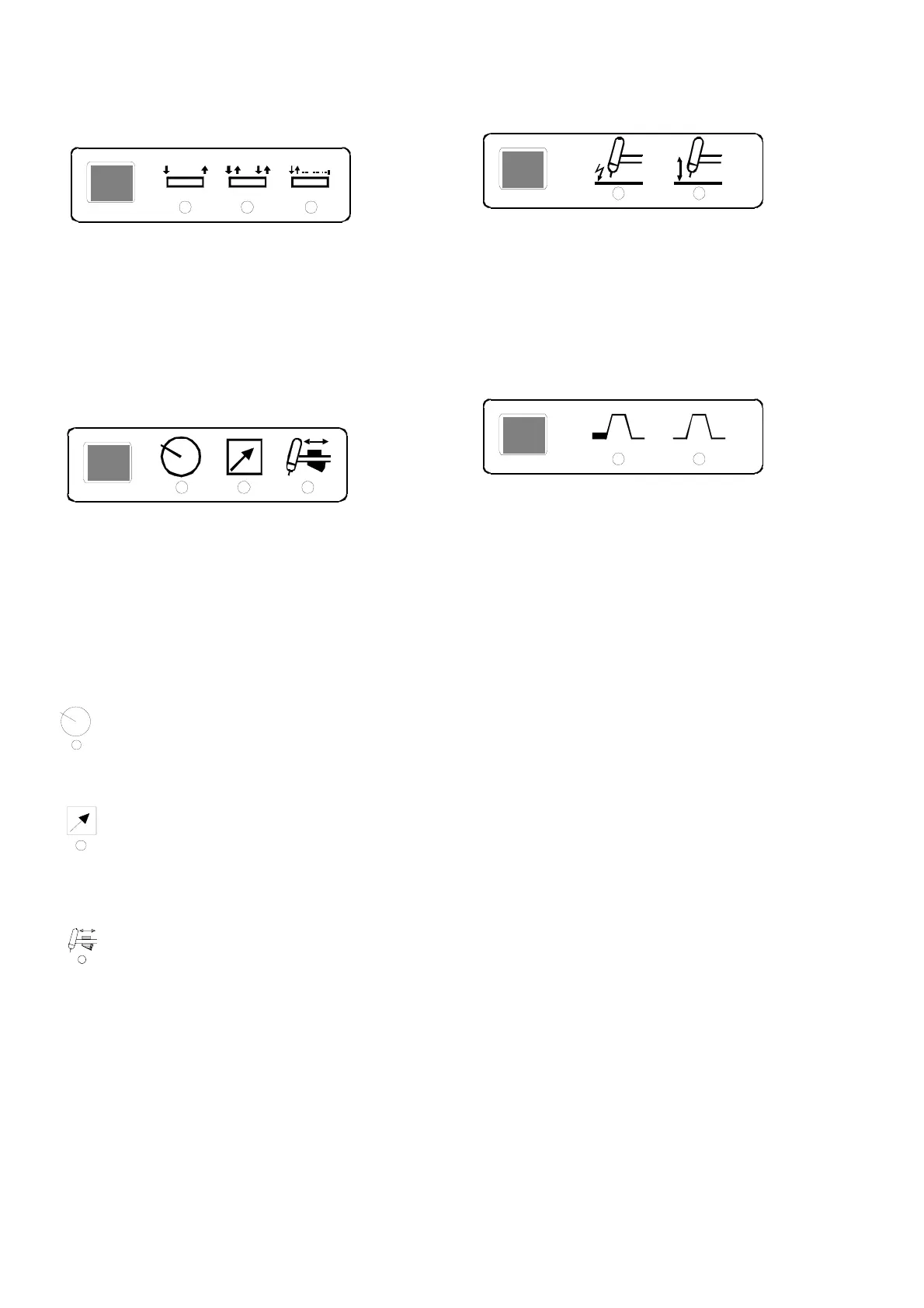

The triggermethod

Two Four Spot

times times

This display is used to decide if the start/stop method

of the TIG welding process is to be two-times, four-

times (latching), or spot.

It is not possible to change to another method of

trigger control during the welding process.

D

AMP Setting function

The AMP keypad is used to select the method by

which the required welding current shall be

established. This welding current is then shown in the

digital display.

The three options are as follows:

D1

Internal

The control knob positioned below the digital

display is used to set the current.

D2

External:

Current setting to be by means of a MIGA-

TRONIC remote control unit. The remote

control unit is connected to a plug positioned on

the rear of the machine (not standard equipment).

D3

Torch:

Torch adjustment

Current setting to be by means of the current control

knob located in the handle of a MIGATRONIC dialog

torch, if a dialog torch is used.

With regard to torch handle current control, it should

be noted the maximum current is set with the control

knob on the front panel. The torch control is used to

reduce the current from the maximum set current. The

adjustment of the machine must not be at the maxi-

mum setting by low current. (From software version

2.20 it is only possible to adjust 100 Amp lower than

maximum current).

E

HF Ignition of TIG welding

LIFTIG It is possible to choose between two

different methods of ignition for TIG wel-

ding: High-frequency (HF) and Liftig ignition.

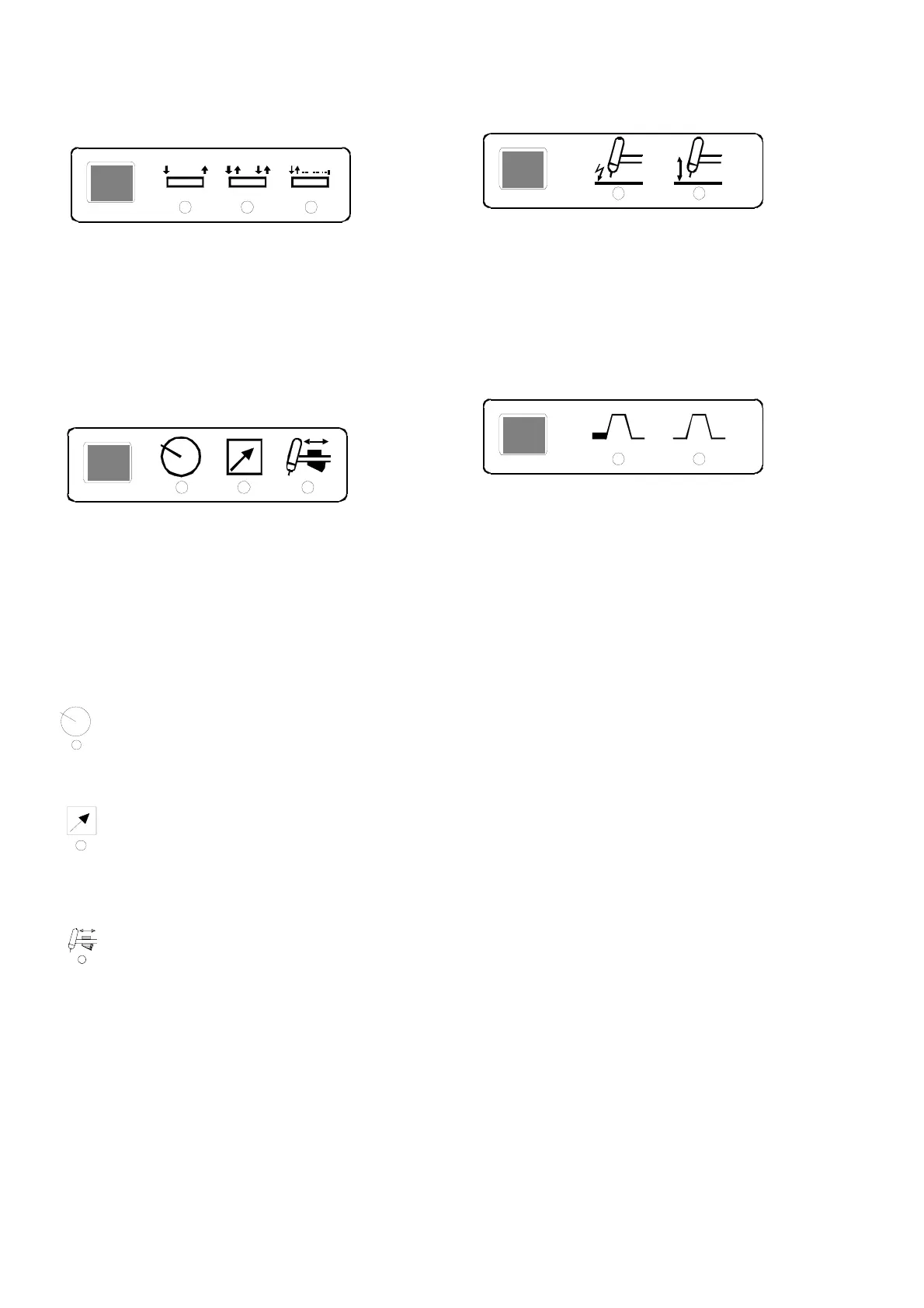

F

ON OFF

Pilot arc

Used only in the TIG welding process, a pilot arc is a

weak arc which illuminates the workpiece, and there-

by makes it easier to find the starting point of the

actual welding process. The pilot arc function is 5% of

the chosen welding current, but 5 A is set as a

minimum.

The pilot arc can be ignited by briefly activating the

torch switch (less than 0.3 seconds). If activation is

longer, the machine switches automatically to ordinary

welding.

Switch from pilot arc to ordinary welding by keeping

the torch switch activated when two-times TIG

welding, or by long activation (> 0.3 seconds) when

four-times TIG or spot welding.

The welding process then continues in normal

fashion, with current slope-up and current slope-

down. However, after slope-down the machine does

not switch directly to post-flow but to pilot arc again.

This is true whether or not welding is initiated by the

pilot arc.

It is now possible to continue with a new welding

process by a lengthy activation of the torch switch

(>0.3 seconds), or to go to standby automatically by

a brief activation (<0.3 seconds).

The machine will also go to standby automatically if

the arc has been extinguished for more than 2

seconds.

To summarise, the pilot arc is switched on and off by

brief activation of the torch switch, and actual welding

is started and stopped by longer activation.

Loading...

Loading...