Migomag SIM 200 LCD

Model No ASIM200LCD

16

Installaon

1. Power Requirement

AC single phase 240V, 50/60HZ fused with a 25 amps me delayed fuse or 36 AMP circuit

breaker is required. Check with local requirements for your situaon.

WARNING:

• High voltage danger from power source! Consult a qualied electrician for proper

installaon of receptacle. This welder must be grounded while in use to protect the

operator from electrical shock.

• Do not remove grounding pin on plug in any way. This will void your warranty. Do not

use any adapters between the welder’s power cord and the power source receptacle.

Make sure the POWER switch is OFF when connecng your welder’s power cord to a

proper power point 240Vac, 50/60Hz, single phase, 15 amp power source.

2. Extension Cord

During normal use an extension cord is not necessary. It is strongly recommended that

an extension cord should be 15 AMP. This drop in voltage can aect the performance of

the welder. If you need to use an extension cord it must be a 15 AMP power lead at the

smallest 2.5m sq cable.

• Do not use an extension cord over 50 . in length

3. Seng up the Work Piece

3.1 Welding posions

There are two basic posions for welding: Flat and Horizontal. Flat welding is generally

easier, faster, and allows for beer penetraon. If possible, the work piece should be

posioned so that the bead will run on a at surface.

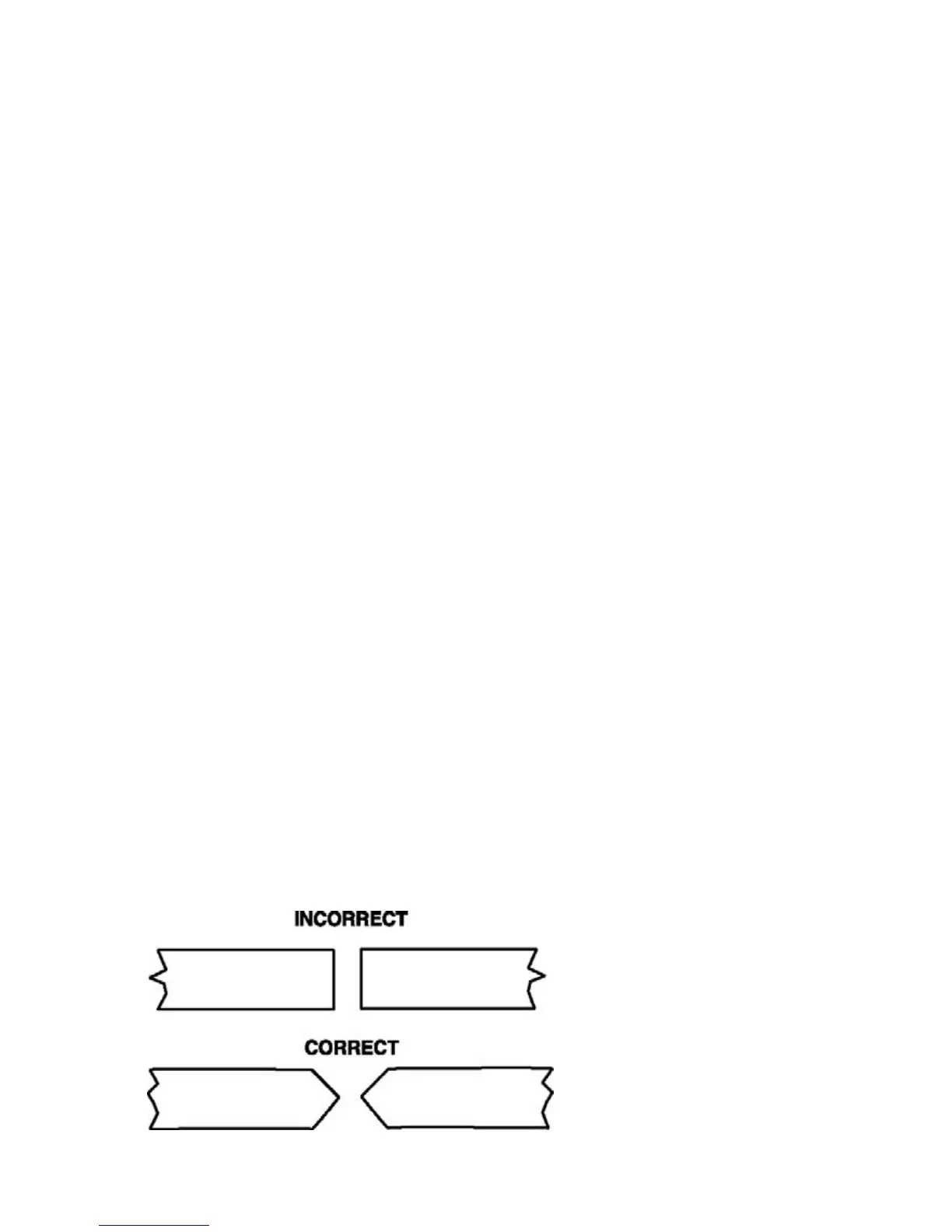

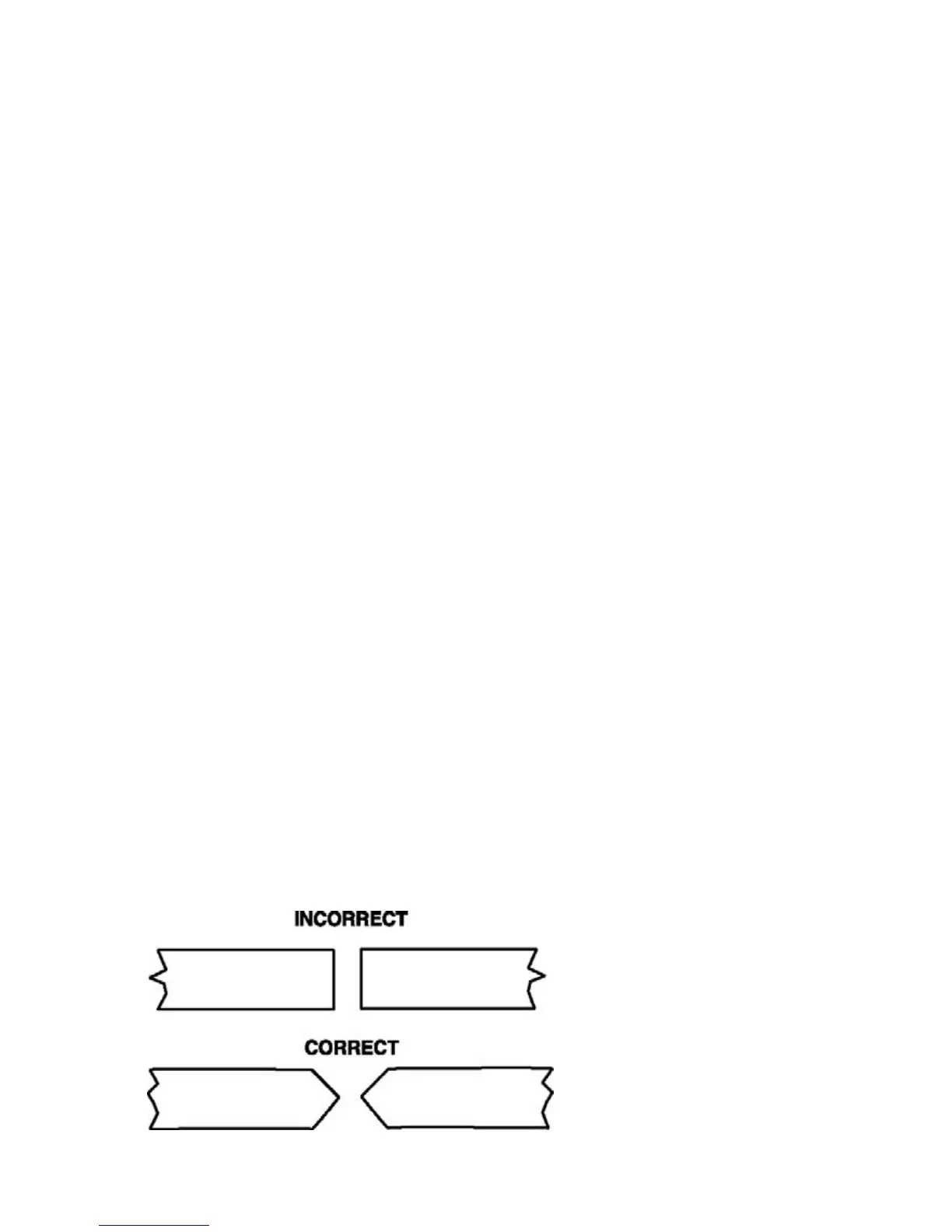

3.2 Preparing the Joint

Before welding, the surface of work piece needs to be free of dirt, rust, scale, oil or paint.

Or it will create a brile and porous weld. If the base metal pieces to be joined are thick

or heavy, it may be necessary to bevel the edges with a metal grinder. The correct bevel

should be around 60 degrees.

See following picture:

Loading...

Loading...