Migomag SIM 200 LCD

Model No ASIM200LCD

30

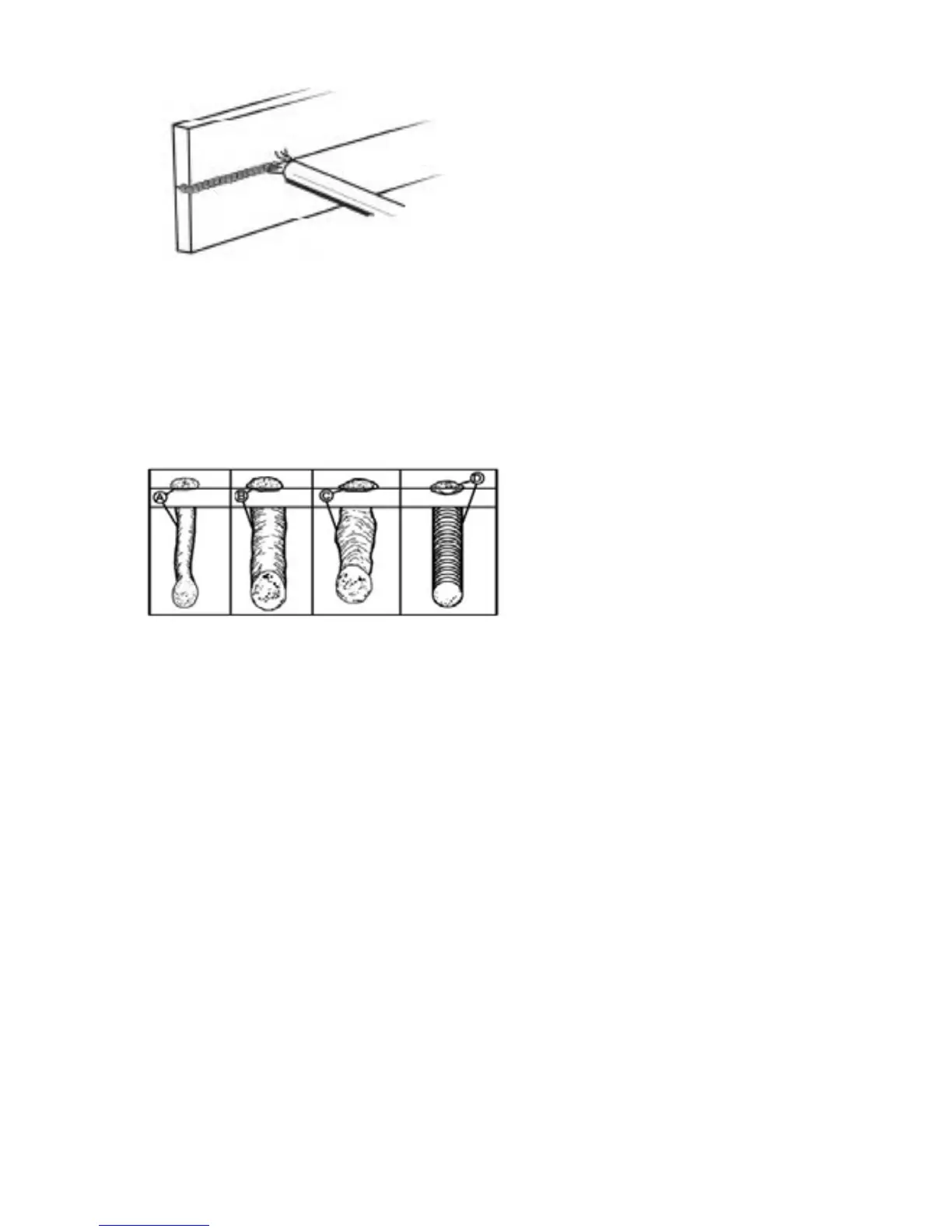

2.5 Judge a good weld bead

When the trick of establishing and holding an arc has been learned, the next step is

learning how to run a good bead. The rst aempts in pracce will probably fall short of

acceptable weld beads. Too long of an arc will be held or the travel speed will vary from

slow to fast. See following:

A. Weld speed is too fast

B. Weld speed is too slow

C. Arc is too long

D. Ideal weld

A solid weld bead requires that the electrode be moved slowly and steadily along the

weld seam. Moving the electrode rapidly or erracally will prevent proper fusion or create

a lumpy, uneven bead. To prevent ELECTRIC SHOCK, do not perform any welding while

standing, kneeling, or lying directly on the grounded work.

2.6 Finish the bead

As the coang on the outside of the electrode burns o, it forms an envelope of

protecve gasses around the weld. This prevents air from reaching the molten metal and

creang an undesirable chemical reacon. The burning coang, however, forms slag. The

slag formaon appears as an accumulaon of dirty metal scale on the nished weld. Slag

should be removed by striking the weld with a chipping hammer.

Loading...

Loading...