How to troubleshoot no weld output on a Miller Welding System?

- JJacqueline BarnesAug 2, 2025

To troubleshoot no weld output on your Miller Welding System, check the line fuses and replace them if necessary.

How to troubleshoot no weld output on a Miller Welding System?

To troubleshoot no weld output on your Miller Welding System, check the line fuses and replace them if necessary.

How to fix a Miller Welding System that requires longer than normal weld time?

If your Miller Welding System requires a longer than normal weld time, consider the following: dress or replace the tips, clean the workpieces, adjust the tong pressure, clean the ends of the tongs and tong holders, and check the input line voltage.

What to do if my Miller LMSW-52 Welding System has low weld output?

If your Miller Welding System has low weld output, try the following: Dress or replace the tips, check the tip threads and replace if necessary, remove and clean the tongs, clean the ends of the tongs and tong holders, and check the start switch S1, replacing it if necessary.

What to do if my Miller LMSW-52 Welding System has no weld output?

If your Miller Welding System isn't producing any weld output, start by checking the line fuses and replace them if needed. For 220 V models, inspect fuse F1 and replace it if necessary. Additionally, dress or replace the tips, and check the tip threads, replacing the tips if required.

How to prevent burn through at the point of weld with Miller LMSW-52?

To prevent burn through at the weld point with your Miller Welding System, try shortening the weld time, adjusting the tong pressure, dressing or replacing the tips, and realigning the tips.

Details potential dangers like fire, explosion, and electric shock from resistance spot welding.

Warns about the dangers of electric shock from live electrical parts and improper grounding.

Warns about burns from touching hot parts and the need for cooling periods.

Alerts to injury risks from moving parts like tongs and linkages during operation.

Explains the health risks associated with welding fumes and gases and ventilation requirements.

Provides technical specifications for different models including AC input, work capacity, and dimensions.

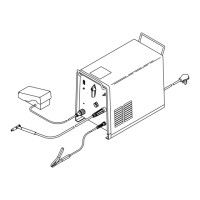

Details the process of installing new welding tips or dressing existing ones.

Guides on how to install or clean the welding tongs for optimal performance.

Provides solutions for common problems like no weld output or low weld output.

| Brand | Miller |

|---|---|

| Model | LMSW-52 |

| Category | Welding System |

| Language | English |