How to fix low weld output on my Miller Millermatic 211?

- SStephen HensonAug 16, 2025

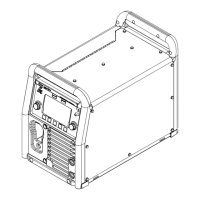

To address a low weld output on your Miller Welding System: * Connect the unit to the correct input voltage or check for low line voltage. * Ensure the Power switch is in the On position.