Do you have a question about the Miller millermatic 200 SKP-35 and is the answer not in the manual?

| Amperage Range | 30 - 200 A |

|---|---|

| Input Voltage | 230 V |

| Input Phase | Single Phase |

| Output Current Range | 30 - 200 A |

| Duty Cycle | 60% at 200 A |

| Wire Feed Speed | 50 - 700 in/min |

| Wire Size Range | 0.023-0.045 in |

General safety advice covering burn prevention, toxic fumes, fire, gas, and shock.

Specific safety precautions for arc welding operations.

General information and safety instructions for equipment operation.

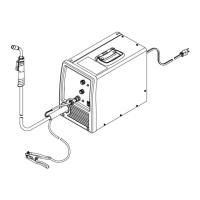

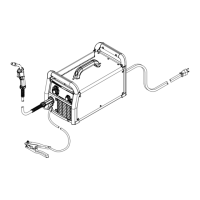

Overview of the unit's design and primary use as a DC arc welding system.

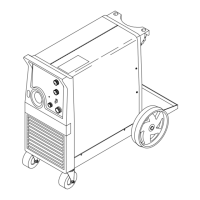

Instructions for installing the running gear and cylinder rack.

Guide to diagnosing and resolving common equipment problems.

Shows the main circuit diagram for the welding power source.

Provides the circuit diagram for the motor control board.

Details the circuit diagram for the optional SKP-35 panel.

Shows the circuit diagram for the SKP-35 panel circuit board.

Illustrates the wiring diagram for the welding power source.

Techniques for performing continuous seam welding with GMAW.

Techniques for performing pulsed seam welding with GMAW.

Techniques for performing spot welding with GMAW.

Guide to identifying and correcting issues in the GMAW process.

Tips for welding sheet metal in auto body repair.

Basic guidelines for welding mild or high-strength steels.

Steps for repairing door panels in automotive applications.

Steps for welding car fenders and quarter panels.

Techniques for welding high-strength steels in automotive frames.