Do you have a question about the Miller Millermatic 250 and is the answer not in the manual?

Outlines warranty periods for parts and labor for various equipment components.

Lists items and conditions not covered by the limited warranty.

Lists modifications or deletions for Section 6.

Lists modifications or deletions for Section 7.

Details risks and precautions related to electric shock during welding.

Covers safety regarding noise, hazardous fumes/gases, and gas cylinder handling.

Safety measures to prevent fire and explosion hazards during welding operations.

Safety guidelines for engines, fuel, moving parts, batteries, and coolant.

Discusses electromagnetic fields (EMF) from welding and their effects.

Provides advice for pacemaker wearers regarding EMF exposure.

Details a schedule for routine maintenance tasks for the welding equipment.

Provides a table to diagnose and resolve common welding machine problems.

Explains safety alert symbols, signal words, and general safety rules.

Lists detailed technical specifications for the welding power source.

Provides specifications for the welding gun, including rated output and duty cycle.

Illustrates normal and overload volt-ampere curves for the welding power source.

Explains duty cycle and its impact on welding equipment, showing a chart and examples.

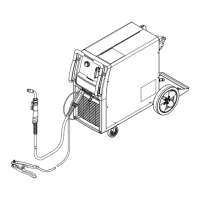

Provides safety and operational guidelines for choosing a suitable installation location.

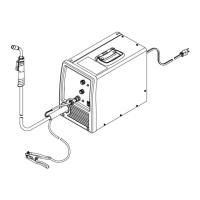

Step-by-step instructions for correctly installing the work clamp.

Explains how to change the gun polarity based on the wire type.

Details connecting the shielding gas cylinder, regulator, and hose.

Step-by-step guide for installing the drive rolls and wire inlet guide.

Instructions on how to connect the welding gun to the power source.

Instructions for setting jumper links according to the available input voltage.

Provides a guide for electrical service requirements, including wire size and length.

Instructions for installing the wire spool and setting the hub tension.

Step-by-step guide on how to safely thread the welding wire through the system.

Identifies and describes the main controls and indicators on the welding unit.

Lists essential safety equipment to be worn during welding operations.

Describes the operation of the main power switch and the pilot indicator light.

Explains the function of the wire speed and voltage controls on the standard panel.

Details the functions of the gun switches for controlling weld programs and parameters.

Outlines the typical sequence of steps for operating the welding equipment.

Explains how to use the mode select button to navigate programming options.

Explains how to use the increase/decrease buttons to adjust parameter values.

Explains how to set wire speed, voltage, and memory in Weld mode.

Details how to set spot, skip, or burnback times in Timer mode.

Explains how to set wire type, gas type, and metal thickness in Material mode.

Instructions for setting language, wire feed units, and burnback time.

Step-by-step guide for manually setting voltage and wire speed parameters.

How to use the microprocessor to set material, gas, and wire type.

Instructions for creating spot or skip weld programs using timer settings.

Details on how to set up and use dual schedule welding for alternating weld programs.

How to use a single switch to control voltage and wire speed for synergic welding.

Outlines regular maintenance tasks and their recommended frequency.

Instructions for correctly aligning the drive rolls and wire guide.

How to inspect and replace the motor brushes in the welding unit.

Explains circuit breaker, unit overload, and overheating protection.

Instructions for replacing the contact tip and liner of the welding gun.

Detailed steps for removing and installing a new gun liner.

Instructions on how to reset the welding unit's memory to factory defaults.

Lists common problems and their remedies, referencing relevant sections.

A diagnostic procedure to check the functionality of various components.

Explains troubleshooting steps for specific display messages on microprocessor models.

Provides circuit diagrams for the welding power source.

Exploded view diagram showing the main assembly components of the welding unit.

Exploded view diagram of the front panel and its components.

Exploded view diagram of the center baffle and its associated parts.

Exploded view diagram of the rear panel and its components.

Diagram showing the components of the main SCR rectifier assembly.

Guide for selecting the correct drive rolls and wire guides based on wire diameter.

Exploded view diagram of the M-25 and M-25M welding gun.

Details the Spoolmatic 30A spool gun accessory.

Describes the WC-24 control module for spool gun operation.

| Brand | Miller |

|---|---|

| Model | Millermatic 250 |

| Category | Welding System |

| Language | English |