Do you have a question about the Miller Millermatic 35 and is the answer not in the manual?

MILLER's obligation is limited to repairing or replacing defective parts within the warranty period.

Defines warranty duration: 90 days for MillerMatic, 1 year for other parts, 3 years for main rectifier diodes.

Using non-MILLER parts in the power or wire feed portions voids the warranty.

General rules apply to various welding generators and machines for maximum personal safety.

Never overload or use worn/poorly connected welding cables. Inspect and repair cables frequently.

Do not use holders with defective jaws or loose cable connections. Use insulated holders.

Machine installation and maintenance must follow National Electrical Code and local requirements.

Never use the welding machine without grounding the frame or case to prevent electrical shock.

Never weld on containers that held combustibles without proper cleaning and purging.

Do not weld on hollow castings that have not been properly vented, as they may explode.

Never weld in or near explosive atmospheres created by flammable materials.

Do not weld where chlorinated hydrocarbon vapors can decompose into toxic phosgene.

Keep combustibles away from the arc, heated metal, slag, or sparks.

Always open power circuits before working on wiring. Never touch electrically 'hot' parts.

Never work in damp areas without insulation. Keep hands, feet, and clothing dry.

Wear proper, dry, oil-free clothing. Wear leather or asbestos gloves at all times.

Never pick up hot objects. Avoid contact with hot metal and discarded electrode stubs.

Never do any chipping or grinding without protective goggles.

Follow precautions for handling and storing compressed gas cylinders to prevent accidents.

This manual familiarizes personnel with design, installation, operation, and maintenance of the welding machine.

Inspect for shipping damage; file claims with the carrier. Provide serial/stock/model numbers when requesting info.

Describes the silicon diode rectifier DC type machine for Gas Metal-Arc Welding (GMAW).

Read the complete safety section before operation to avoid injury due to misuse.

Defines CAUTION, IMPORTANT, and NOTE blocks for safe operation and maintenance.

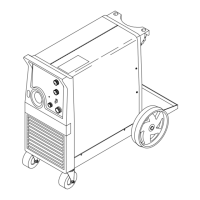

Procedure for installing the welding machine on optional running gear.

Proper location ensures satisfactory service, ventilation, and prevents obstructions.

Instructions for connecting the welding machine to the primary power source.

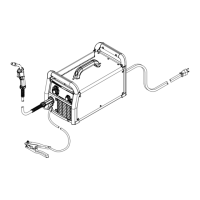

Instructions for installing the work clamp onto the work cable.

Procedure for installing and adjusting the gas regulator for CO2 or Argon/CO2 mixtures.

Steps for installing the wire spool and components onto the drive assembly.

Procedure for threading the welding wire through the gun and into the drive assembly.

Instructions for operating the welding machine using the Gas Metal-Arc Welding process.

Read instructions before operating. Practice welds on sample metal are recommended.

Proper gun techniques and essential pre-weld checks for safe operation.

Operating instructions for models that include spot welding functionality.

Covers spot welding controls, nozzle selection, and operational steps.

Procedure to check and calibrate the wire feed speed for optimal performance.

Procedures for removing, cleaning, and inserting the monocoil assembly.

Instructions for removing upper and lower drive roll gears from the drive assembly.

Procedure for installing upper and lower drive roll gears into the drive assembly.

Explains the function and reset procedure for circuit breakers.

Addresses low output fan motor speed due to jumper link or low primary voltage.

Covers defective fan motor, loose connections, or blown primary fuses.

Identifies issues with primary fuses, disconnect switch, or the ON-OFF power switch.

Checks primary fuses, primary connections, disconnect switch, and circuit breaker.

Addresses defective rectifier diodes or loose secondary connections.

Covers defective gun switch, contactor coil, or plug security.

Identifies issues with transformer, circuit breakers, interlocks, or wire feed controls.

Focuses on issues specific to spot mode, like Q51, spot panel rectifier, or contacts.

Addresses Q51, spot panel rectifier, resistors, or coil defects in spot mode.

Covers issues with diodes, resistors, or transformers affecting spot timer functions.

| Brand | Miller |

|---|---|

| Model | Millermatic 35 |

| Category | Welding System |

| Language | English |