What to do if Miller Welding System has low, high, or erratic wire speed?

- EEric RichardsAug 2, 2025

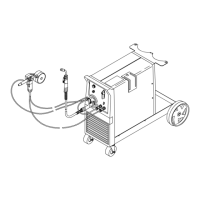

If you experience low, high, or erratic wire speed with your Miller Welding System, try the following: * Readjust the front panel settings. * Change to the correct size drive roll. * Readjust the drive roll pressure. * Replace the inlet guide, contact tip, and/or liner if necessary.