What to do if the Temperature status light is on for Miller Welding System?

- Jjohn09Sep 7, 2025

If the temperature status light is on, the unit is overheating. Allow the fan to run, and the light should go out when the unit has cooled down.

What to do if the Temperature status light is on for Miller Welding System?

If the temperature status light is on, the unit is overheating. Allow the fan to run, and the light should go out when the unit has cooled down.

What to do if Trouble lights are on and unit has no cutting output on Miller Spectrum 625 X-TREME?

If the trouble lights are on and the unit has no cutting output, check the torch consumables and ensure there is gas/air flow at the torch. Verify the air supply connection and pressure to the unit and torch. Try resetting the unit power switch.

What to do if pilot arc is working but there is no cutting output on Miller Spectrum 625 X-TREME Welding System?

If the pilot arc is working but there's no cutting output, ensure the work clamp is connected. Additionally, clean or replace worn consumables as necessary.

What to do if Pressure status light flashes on Miller Spectrum 625 X-TREME?

If the pressure status light flashes, it indicates the unit momentarily lost pressure while cutting. Check the air line for leaks.

| Output Range | 20 - 50 A |

|---|---|

| Process | Plasma Cutting |

| Amperage Range | 20 - 50 A |

| Maximum Open-Circuit Voltage | 300 VDC |

| CNC Interface | Yes |

| Rated Output | 50 A / 60% Duty Cycle |

| Duty Cycle | 60% |

Explains symbols used for warnings and instructions within the manual.

Details hazards associated with plasma arc cutting, including fire, electric shock, and fumes.

Covers additional safety symbols for installation, operation, and maintenance procedures.

Provides warnings related to chemicals in the product that may cause birth defects or cancer.

Lists key safety standards and organizations relevant to welding and cutting equipment.

Explains electromagnetic fields (EMF) and their potential interference with medical implants.

Explains the meaning of safety symbols used in the manual.

Details hazards related to plasma arc cutting, covering fire, electric shock, and fumes.

Covers additional hazards related to installation, operation, and maintenance.

Warnings about chemicals known to cause birth defects or cancer in California.

Lists principal safety standards relevant to welding and cutting.

Information on electromagnetic fields (CEM) and medical implants.

Defines additional safety symbols, some specific to CE products.

Provides definitions for various miscellaneous symbols used in the manual.

Indicates where to find the serial number and rating label on the unit.

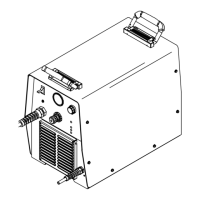

Details electrical specifications, power supply, and output characteristics of the unit.

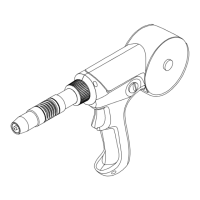

Provides physical dimensions and weight specifications for the XT40 torch.

Explains duty cycle percentages and the causes/effects of overheating.

Lists the physical dimensions and weight of the power source unit.

Details environmental specifications including IP rating and operating temperature range.

Guidelines for choosing a proper and safe location for the equipment.

Instructions on connecting the gas or air supply to the unit.

Procedures for connecting and disconnecting the plasma torch.

Procedures for connecting and disconnecting the work cable.

Details on how to properly connect the work clamp to the workpiece.

Recommendations for electrical service, including voltage, amperage, and conductor size.

Provides guidance on selecting extension cords based on voltage and length.

Instructions for using multi-voltage plug adapters for different power supply configurations.

Steps for connecting the unit to a 120-volt AC input power source.

Instructions for connecting the unit to a 240-volt AC single-phase input power source.

Describes standard front panel controls for operating the unit.

Describes automation front panel controls for operating the unit.

Provides recommended cutting speeds for various materials and thicknesses.

Covers trigger safety lock and best practices for plasma cutting.

Provides step-by-step sequences for cutting, gouging, and piercing operations.

Instructions on how to mount the XT40M torch for mechanized use.

Identifies the remote control receptacle and its purpose for arc start inputs.

Describes the functions of different wires within the remote control cable set.

Illustrates how to connect the remote control cable to the unit's receptacle.

Outlines regular maintenance tasks to keep the equipment in good working order.

Step-by-step guide for safely removing the unit's outer wrapper for access.

Instructions for inspecting and replacing the air filter element.

Procedure for checking the shield cup shutdown system for proper function.

Guide for inspecting and replacing torch consumables like the tip and electrode.

Explains the meaning of various status and trouble lights on the unit.

Provides solutions for common problems related to the power source operation.

Offers troubleshooting steps for issues specific to the plasma torch.

Lists recommended spare parts for the equipment, including part numbers.