OM-234 016 Page 54

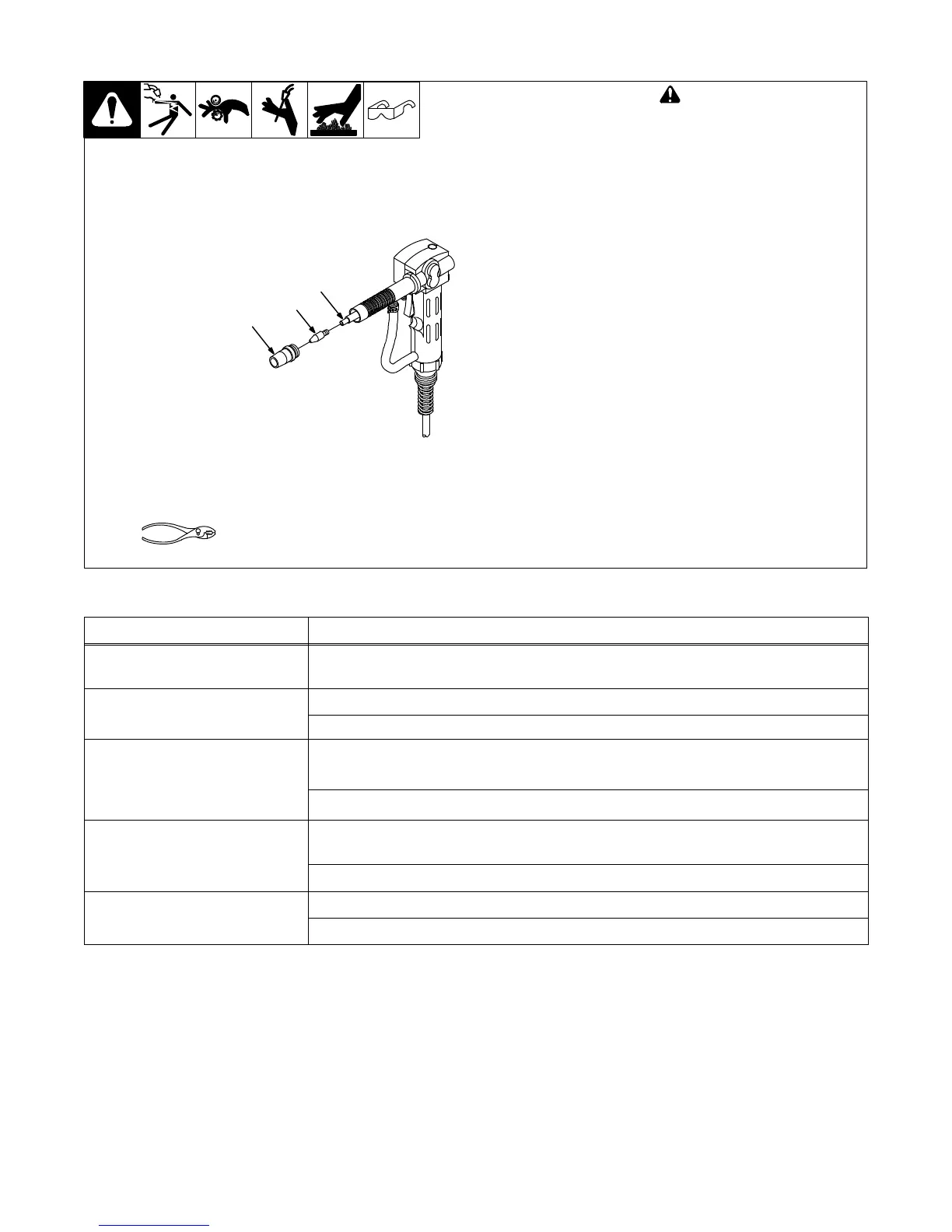

5-3. Changing Liner

Ref. 804 985-A

Tools Needed:

! Turn Off power at welding

power source first.

1 Nozzle

2 Contact Tip

3 Liner

Remove and replace liner.

Reinstall parts as shown.

1

2

3

5-4. Troubleshooting

Trouble Remedy

No weld output; gun/feeder does not

work.

Place Power switch on welding power source in the On position (see welding power source Owner’s

Manual). Check Spool Gun/MIG Gun switch for correct position.

Erratic weld output. Tighten and clean all connections.

Check for proper weld output polarity connections (see Section 3-3B, 3-4, 3-5, 3-6, 3-7, 3-8 ).

Pressing gun/feeder trigger does not

energize welding power source; welding

wire is not energized; shielding gas does

not flow.

Secure plug from gun/feeder trigger cord into 4-socket receptacle on welding power source (see Section

3-3B, 3-4, 3-5, 3-6, 3-7, 3-8).

Place Spool Gun/MIG Gun switch in Spool Gun position (see Section 3-3B, 3-4 or 3-6).

Wire feeds, shielding gas flows, but

welding wire is not energized.

Secure spool gun cable connector to wire drive assembly inside welding power source (see Section

3-3B, 3-5 or 3-6).

See Troubleshooting section in welding power source Owner’s Manual.

Wire feeds erratically. Check and correct drive roll pressure (see Section 3-10).

Clean or replace drive roll; clean or replace liner (see Sections 5-2 and 5-3).

Loading...

Loading...