Z

zwilliamsJul 28, 2025

How to fix low power output at AC receptacles on a Miller Welding System?

- CcrodriguezJul 28, 2025

If your Miller Welding System has low power output at the AC receptacles, increase the Fine control R1 setting to the maximum.

How to fix low power output at AC receptacles on a Miller Welding System?

If your Miller Welding System has low power output at the AC receptacles, increase the Fine control R1 setting to the maximum.

What to do if Miller Welding System has erratic weld output?

If your Miller Welding System has erratic weld output, try the following: Check the control settings. Ensure connections to the electrode and workpiece are tight and clean. Use dry, properly-stored electrodes for Stick and TIG welding. Remove excessive coils from weld cables. Clean and tighten connections both inside and outside the welding generator. Also, check the engine speed and adjust if necessary. If the problem persists, have a Factory Authorized Service Agent check the brushes, slip rings, integrated rectifier SR1, capacitor C1, and Fine Control R1.

What to do if Miller Welding System has low weld output?

If your Miller Welding System has low weld output, check the control settings. Also, check the engine speed and adjust if necessary. Service the air cleaner according to the engine manual. If the issue continues, have a Factory Authorized Service Agent check the brushes, slip rings, capacitor C1, and integrated rectifier SR1.

What to do if Miller Welding System has no weld output and no generator power output?

If your Miller Welding System has no weld output and no generator power output at the AC receptacles, ensure all equipment is disconnected from the receptacles when starting the unit. Check the plug PLG3 connection. If the problem persists, have a Factory Authorized Service Agent check the brushes, slip rings, capacitor C1, and integrated rectifiers SR1, SR2 and SR3.

What to do if Miller Wildcat 200 Welding System has no generator power output but weld output is okay?

If your Miller Welding System has no or low generator power output at the AC receptacles but the weld output is okay, reset the supplementary protectors. Press the optional GFCI receptacle Reset button. Check the plug PLG3 connection. If problems persist, have a Factory Authorized Service Agent check the brushes, slip rings, and integrated rectifier SR2.

What to do if Miller Wildcat 200 Welding System has high weld output?

If your Miller Welding System has high weld output, check the control settings and the engine speed, adjusting if necessary.

What to do if Miller Wildcat 200 Welding System has no generator power output and no weld output?

If your Miller Welding System has no generator power output at the AC receptacles and no weld output, ensure all equipment is disconnected from the receptacles when starting the unit and check the plug PLG3 connection. If the issue continues, have a Factory Authorized Service Agent check the brushes, slip rings, capacitor C1, and integrated rectifiers SR1, SR2, and SR3.

Covers hazards related to electric shock, engine, hydraulics, compressed air, fire, noise, and EMF.

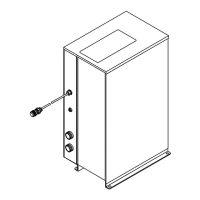

Details welding mode, output, generator power, fuel capacity, and engine specs.

Lists prestart engine checks and guides on battery connection/replacement.

Covers air cleaner servicing, oil/filter changes, and engine speed adjustments.

Lists common welding output problems and their corrective actions.

Details problems with AC receptacle power output and their solutions.

Covers common engine starting and running problems and their remedies.

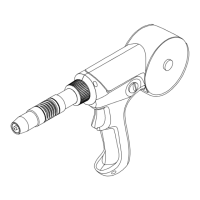

Covers procedures, striking an arc, electrode positioning, bead characteristics, and factors affecting shape.

Provides common weld defects and their corrective actions.

| Engine | Kohler CH270 |

|---|---|

| Input Frequency | 60 Hz |

| Process | Stick (SMAW) |

| Weld Output Range | 50 - 200 A |

| Input Voltage | 120/240V |

| Amperage Range | 5-200 Amps |

| Rated Output | 200 Amps at 25V |

| Output Current Range | 5-200 Amps |

| Input Power | 8, 000 Watts |