C

HAPTER

6 - M

AINTENANCE

39

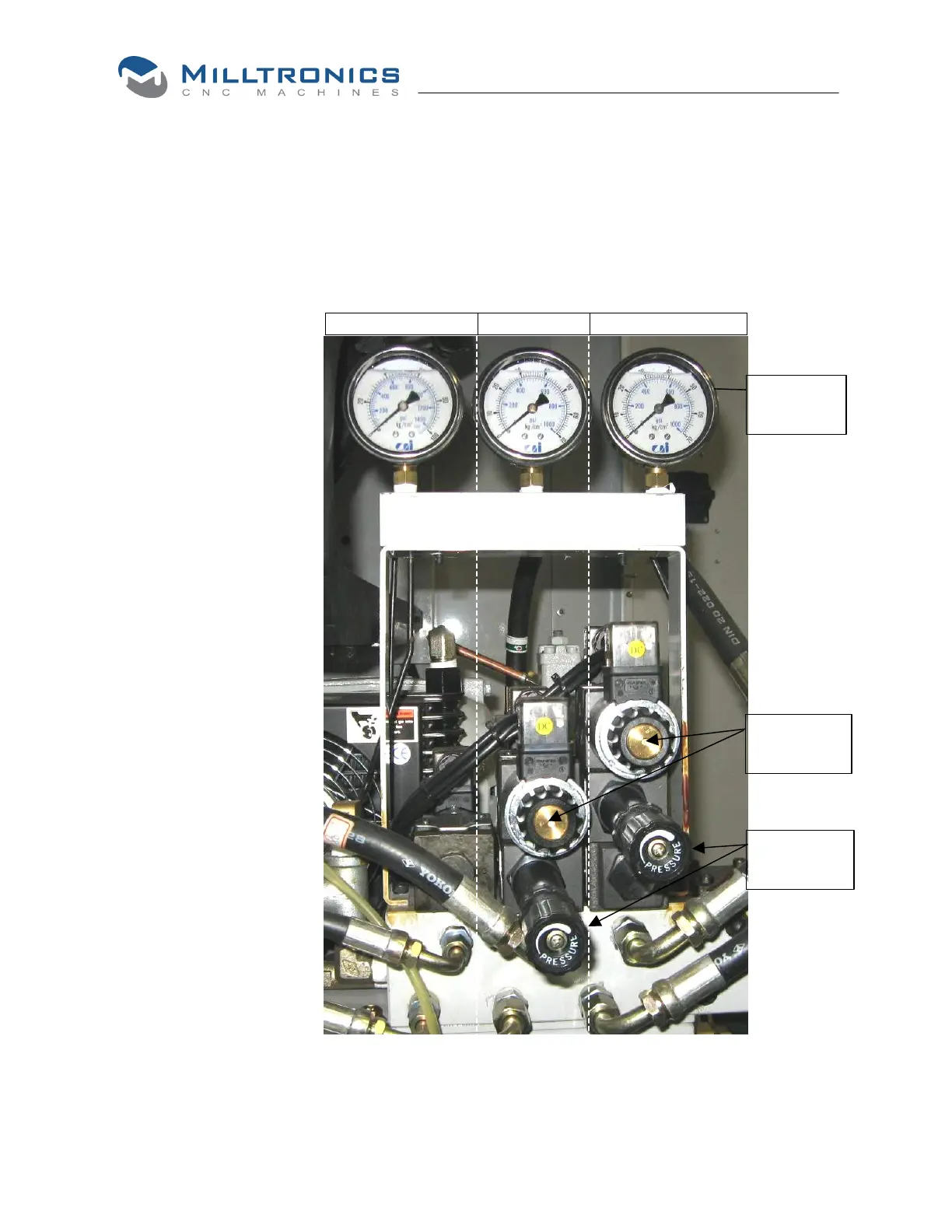

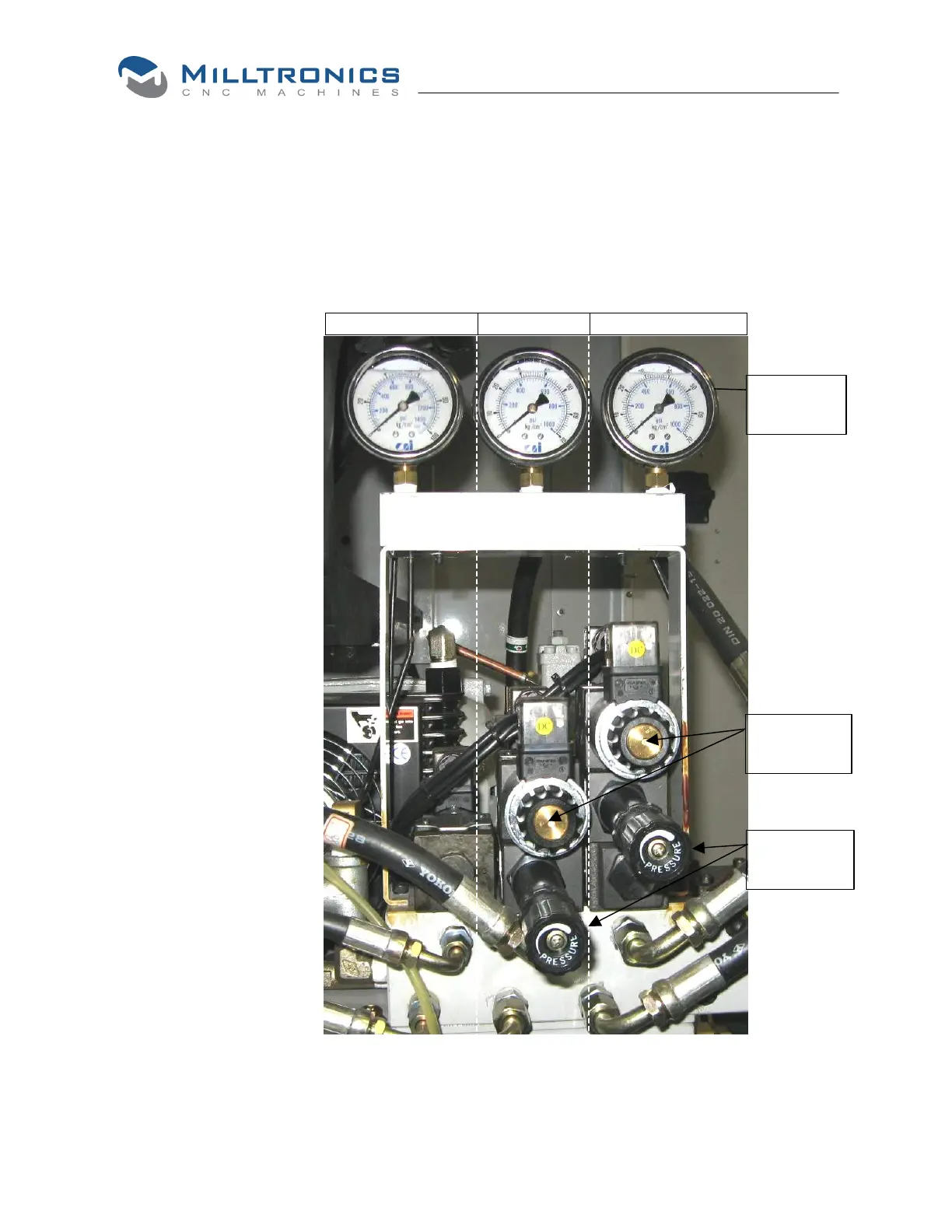

Hydraulic Valves, Pressure Switches, and Gauges

Manual

actuators

Pressure

adjustment

Pressure

gauges

Front View

Parts Catcher Chuck Tailstock

Pressure Regulators

The pressure regulators

are factory set to

200psi. Each regulator

should be adjusted

according to specific job

requirements.

There is no regulator for

the parts catcher valve.

Pressure adjustments

are made using the

to the right where the

larger number

represents higher

pressure, and lower

number represents

lower pressure.

Manual Actuation

The valves can be

actuated manually by

pressing the buttons

shown here and on the

following page.

Switches

When pressure

adjustments are made,

the switches (see

following page) must be

adjusted accordingly.

The factory setting for

the switches is 190psi.

The illustration below shows the arrangement of the hydraulic valves and gauges on

SL6-10 model turning centers. See the following page for additional views.

Loading...

Loading...