Chapter 3. Routine Maintenance

PELLERIN MILNOR CORPORATION

.

CAUTION 28 : Risk of malfunction—The level sensor must give correct data.

• Keep the connecting tube or hose free of blockages and leaks.

• Make sure that the connections are tight.

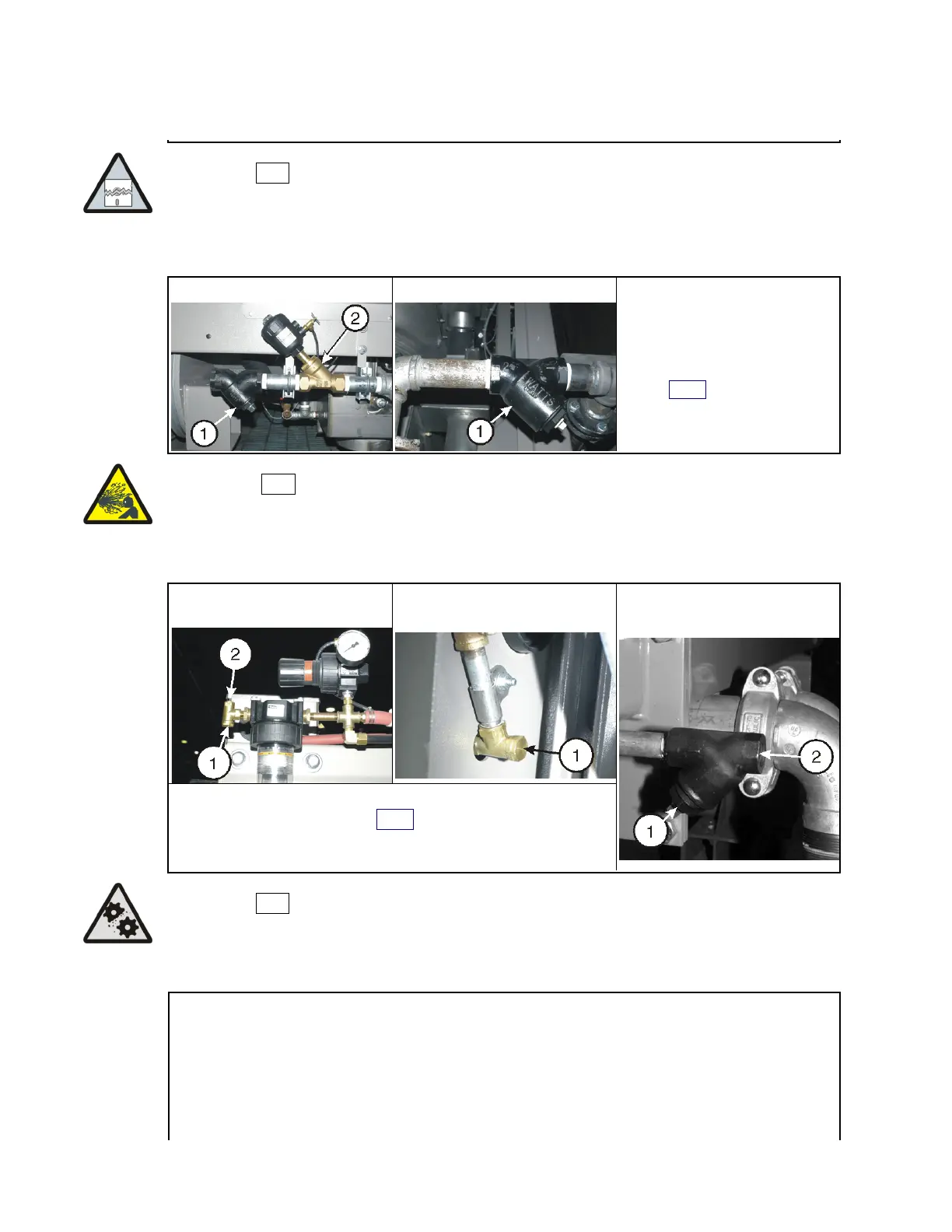

Figure 12: Steam Inlet Strainer. These are examples. Your machine can look different.

42044SP2 Washer-extractor 76039CBW Tunnel Washer Legend

1. Steam strainer. Remove

steam pressure before

you remove the plug. See

warning statement

29

2. Steam valve

.

WARNING 29 : Risk of severe injury—You can accidentally release pressurized steam.

• Close the external shutoff valve and release remaining pressure before you do

maintenance.

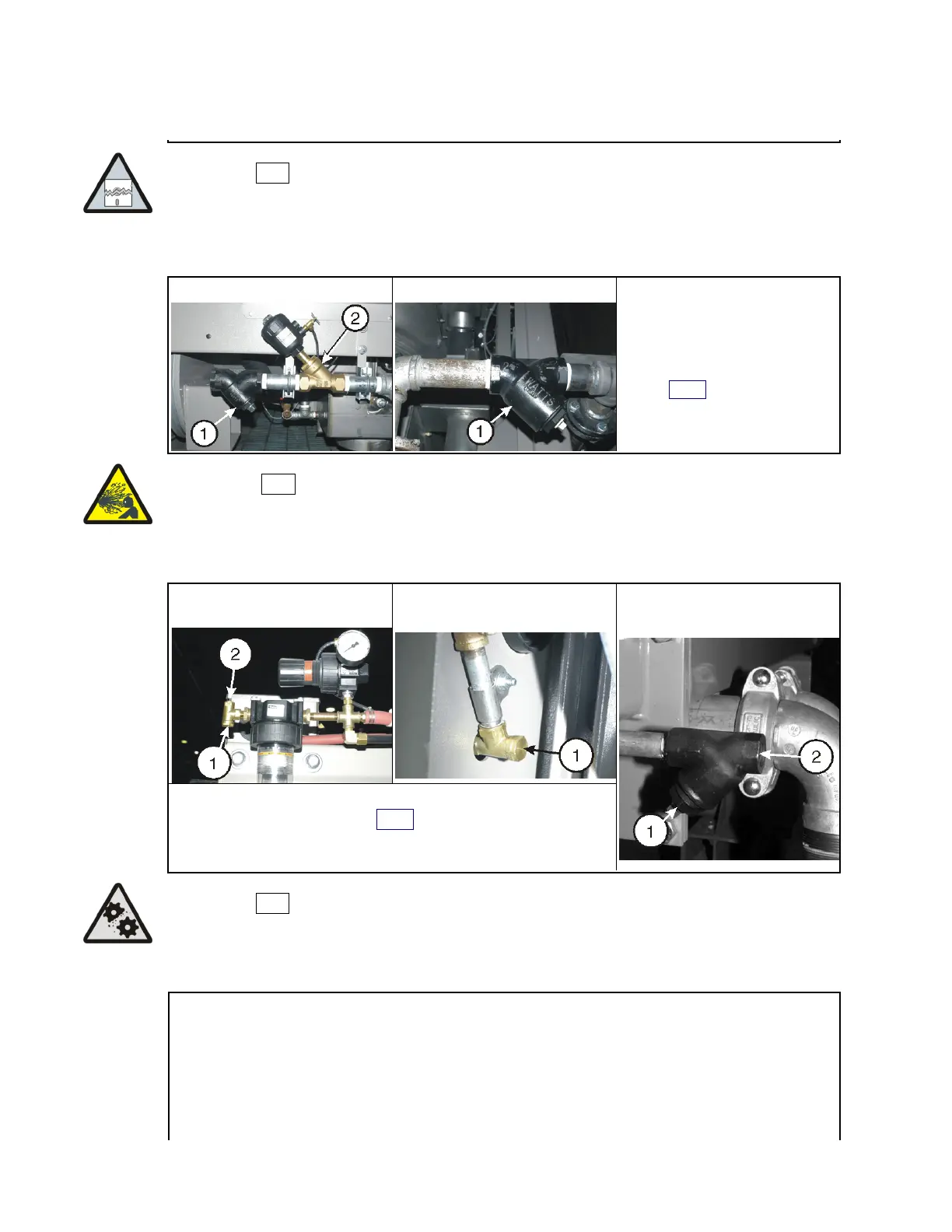

Figure 13: Compressed Air Inlet Strainers. These are examples. Your machine can look different.

T-Strainer. Outside machine

frame on some models.

T-Strainer. Inside machine

frame on some models.

Y-strainer. Used on some

models

Legend

1. See caution statement 30 . Remove plug to remove

strainer.

2. Compressed air in.

.

CAUTION 30 : Risks of injury and damage—

• Close the external shutoff valve and release remaining pressure before you do

maintenance.

Supplement 2

How to Examine Compressed Air Mechanisms

Your machine has one or more mechanisms that use compressed air for movement. Figure 14

shows some examples. To examine a compressed air mechanism, look at the mechanism and

listen to it in operation. Do not touch the mechanism or put your hand in the machine.

Usually you can see movement directly or on a position indicator. Frequently, you can hear a

valve open and close. When a signal from the controller to operate the mechanism occurs, the

air pressure must increase sufficiently before movement occurs. When the signal stops, the

34

Loading...

Loading...