8

4. Calibration method

4−1. Calibration method of torque

There are two kinds of methods of the torque calibration of this instrument.

1

Electrical calibration

The calibration is made electrically by the attached combination inspection data sheet.

2

Actual torque transducer

The calibration is made by applying the rated torque to the torque transducer.

4−2. Preparation before adjustment

Supply the power upon confirming if the torque transducer and power supply are connected

correctly. (Refer to the paragraph 3−3.)

Please take the warming−up of about 15−20 minutes to make this instrument work stabilizing

though this instrument becomes a working condition after turning on the power supply.

4−3. Electrical calibration

Procedure

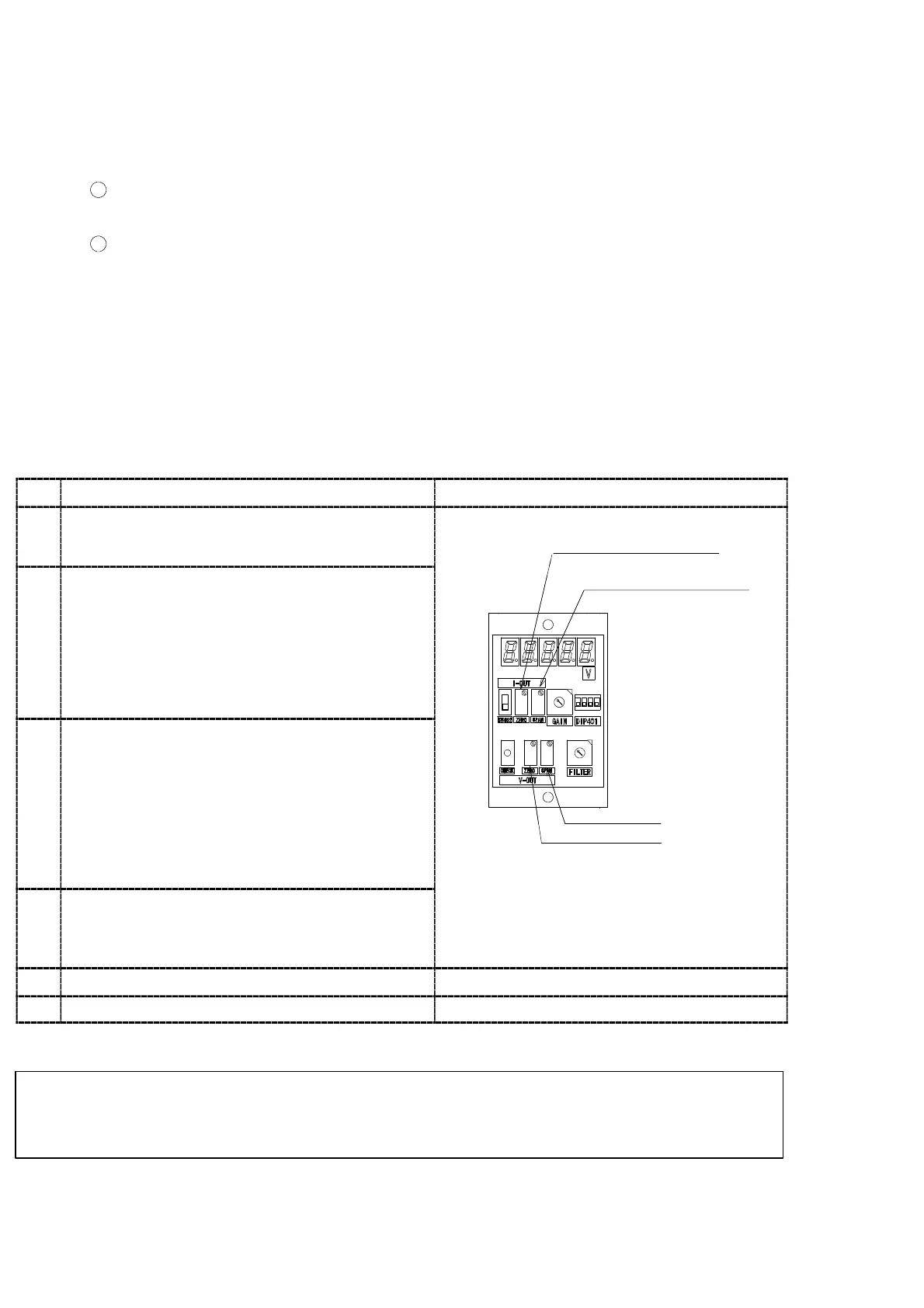

1

The torque transducer is put into the conditon

that an initial torque (condition built into the

device) applys.

ZERO trimmer for

current output

2

Cancel th

initial torque

Adjust the voltage output to 0.000 V or the

current output (option) to 12.00 mA by turning

the ZERO trimmer.

When the voltage output is used together with the

current output (option), the voltage output is

previously adjusted, and then, the current output

(option) is adjusted.

r

mmer

or

voltage output

3

Span adjustment

The output voltage is matched by using SPAN

trimmer to become the CHECK value described in

the inspection data sheet while pressing the

CHECK switch.

When the voltage output is used together with the

current output, the voltage output is previously

adjusted, and then the current output (option) is

adjusted.

SPAN trimmer

ZERO trimmer

4

Readjustment of ZERO point

Leave the had from CHECK switch, and proceed

the step 2 again to adjust the voltage output to

0.000 V and the current output to 12.00 mA.

5

Please confirm step 2 to 4 again.

6

Calibration is completed.

● The output from the Torque transducer will be + voltage output in the counterclockwise

direction and − voltage output in clockwise direction.

The output polarity for the Torque transducer is fixed and can’t be changed.

Loading...

Loading...