— 18 —

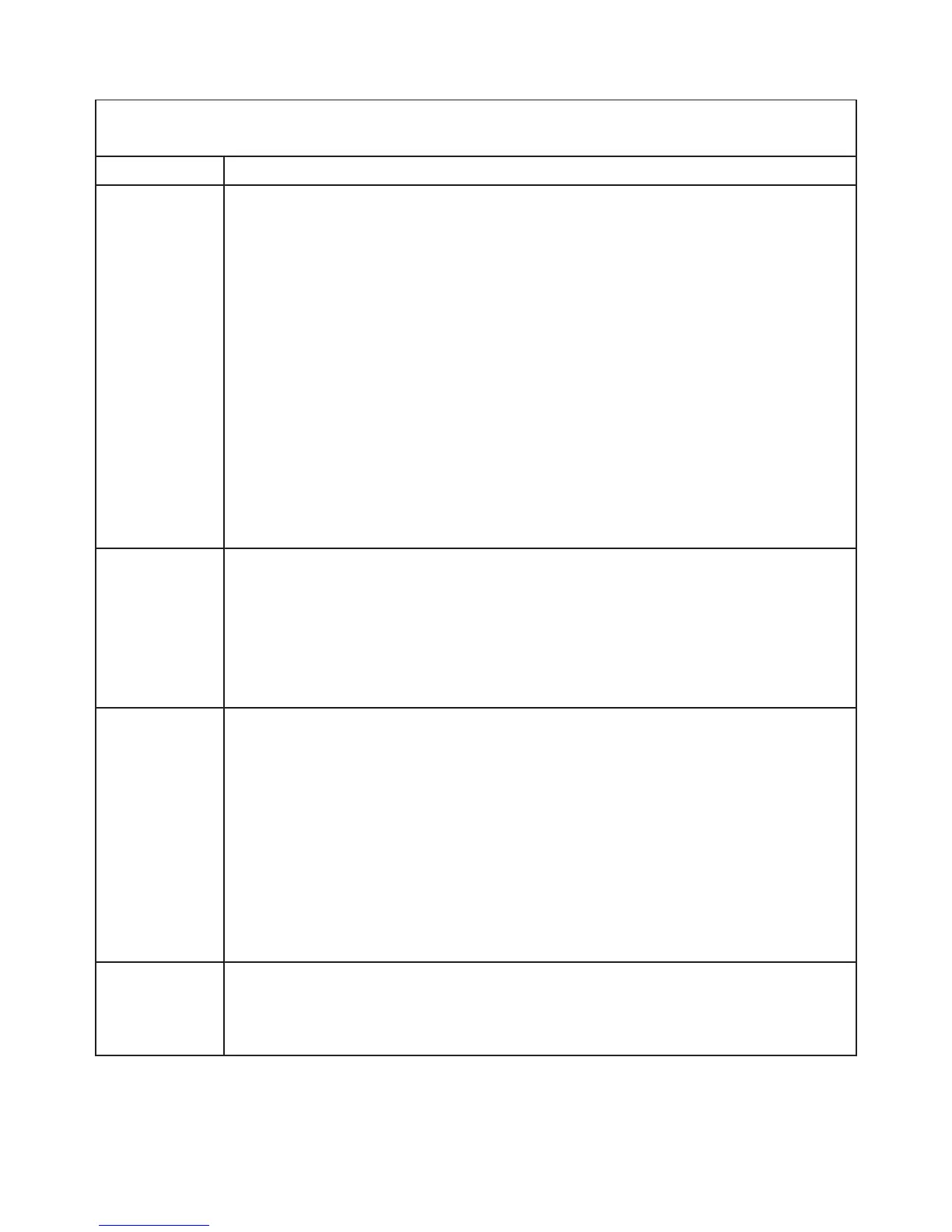

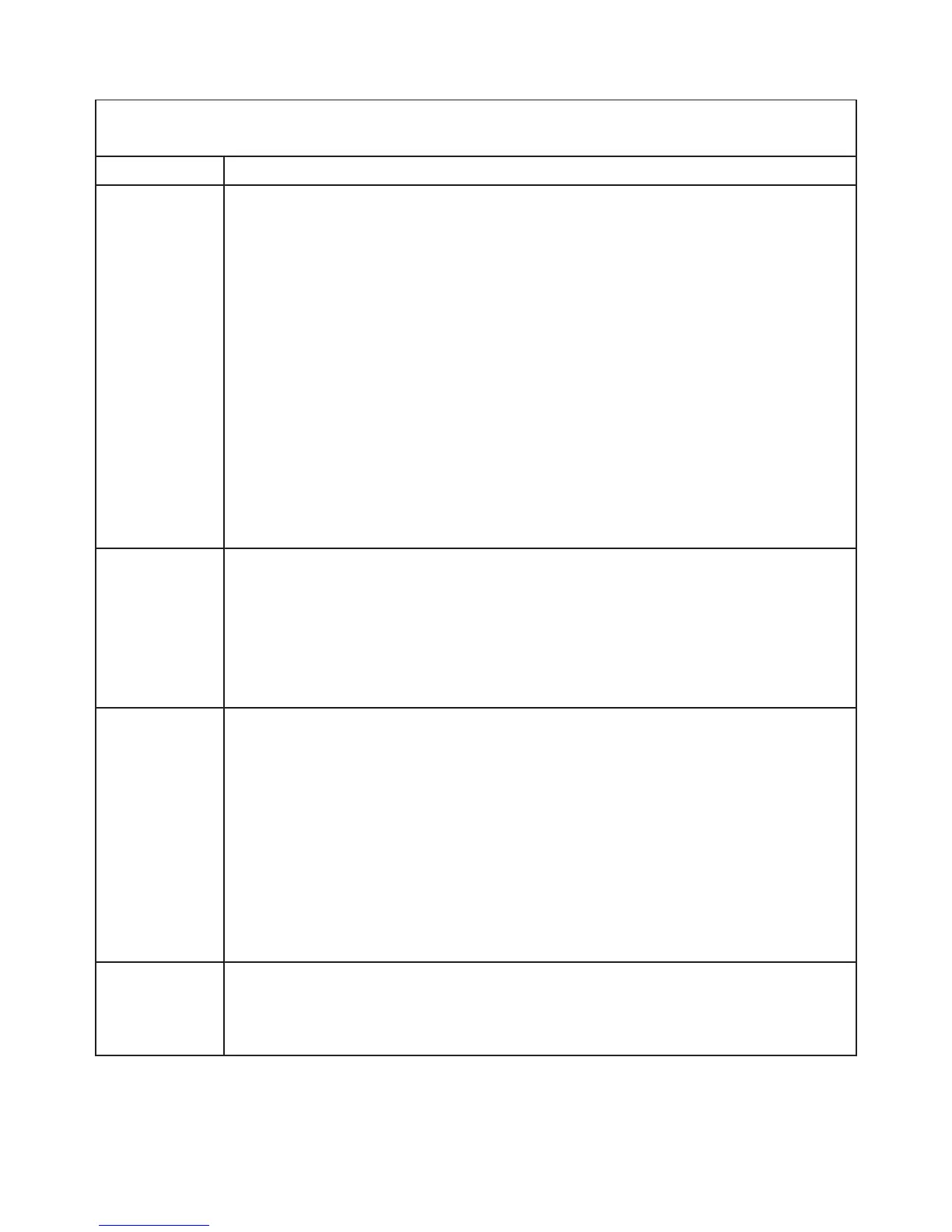

TROUBLESHOOTING GUIDE

TROUBLE

CHECK

UNIT DOES

NOT RUN

AFTER DRIVE

MOTOR HAS

STARTED

1. Make certain 100 volts A.C. exists between terminals 1 (D signal) and 2 (Y2 signal) with the

power switch on. A voltage of approximately 16 volts D.C. between terminals 8 (P1 signal)

and 7(G1 signal) shows presence of the reference voltage. A voltage or approximately 90

volts D.C. between terminals 15 (K1/K3 signal) and 5 (F1/C1 signal) checks the power rectifi-

er bridge. If no D.C. power, or incorrect reference voltage is indicated, suspect trouble in the

control.

2. Make certain that the operator’s speed potentiometer is giving a reference signal to the con-

trol. No excitation of the coupling is possible unless the voltage between terminals 9 (R sig-

nal) and 7 (G1 signal) is at least .7 volt D.C. with terminal 9 (R signal) positive. The voltage

between terminals 9 (R signal) and 7 (G1 signal) will vary from 0 to 16 volts D.C. depending

upon the setting of the speed potentiometer.

3. Check for D.C. output voltage on coupling terminals 5 (F1/C1 signal) and 3 (F2/C2 signal).

With full excitation, terminal 3 (F2/C2 signal) will be as much as 90 volts D.C. positive. If exci-

tation is present, unit should be running unless the coupling coil circuit is open. To check for

open coupling coil, disconnect power to press and remove wires from control terminals 5

(F1/C1 signal) and 3 (F2/C2 signal). Connect ohmmeter leads to these two wires and check

resistance. Normal resistance is approximately 50 to 65 ohms. If measurement indicates

“open,” check coil connections inside motor drive conduit box. Also, recheck coil resistance

from this point. If coupling coil is “open,” contact local area motor repair shop for installation

of new coil.

4. Check setting of torque limit control.

UNIT SLOWLY

DRIFTS IN

SPEED

1. Torque Limiter may be set incorrectly. Reset torque limiting point per instructions in manual.

2. Check for worn speed control potentiometer or loose wiring connections between it and the

control terminal strip.

3. Operating drive at relatively low output speeds may cause excessive loading and resultant

slowdown.

4. Check for erratic tachometer feedback voltage, A.C., between terminals 7 (G1 signal) and 12

(G2 signal). Rapidly changing voltage here may be caused by loose connections, broken or

shorted wires, or a defective tachometer generator.

UNIT RUNS

ONLY AT FULL

DRIVE MOTOR

SPEED

1. Make certain problem is electrical. Check coupling excitation on terminals 5 (F1/C1 signal)

and 3 (F2/C2 signal). Use D.C. voltmeter (start with 0-150 V.D.C. scale). Connect positive

probe to terminal 3 (F2/C2 signal) and negative to 5 (F1/C1 signal). No excitation voltage

means unit is not energized electrically and problem could be mechanical within the drive.

2. Check D.C. voltage between terminals 9 (R signal) (+) and 7 (G1 signal) (-) to make certain it

is zero when the speed potentiometer is turned down. If not, external speed potentiometer

may be shorted or incorrectly connected.

3. Check for presence of tachometer feedback voltage, A.C., between terminals 7 (G1 signal)

and 12 (G2 signal). Without this feedback, unit will run at full speed with only a small refer-

ence voltage applied to terminal R. The tachometer feedback voltage varies from 30 to 60

volts A.C., depending on motor and drive.

4. Turn power switch off on control unit. If the drive remains running, the drive has failed either

through the center bearing locking up or the air gap in the coupling is closed. If this is the

case the motor will need to be repaired by a motor rebuild shop.

FUSES BLOW

1. If operator’s speed potentiometer is turned down and the fuse instantaneously blows an

internal failure may have occurred. Before replacing the unit, check for a direct short across

terminals 5 (F1/C1 signals) and 3 (F2/C2 signals) or terminals 4 (B2 signal) and 6 (C1 sig-

nal). A short indication at this point could be the result of a shorted coupling or brake coil,

lead, or associated component in that circuit.

Loading...

Loading...