3. Product presentation

MiR Precision Docking Operating guide (en) 2019/11 - v.1.2 ©Copyright 2019: Mobile Industrial Robots A/S. 8

3. Product presentation

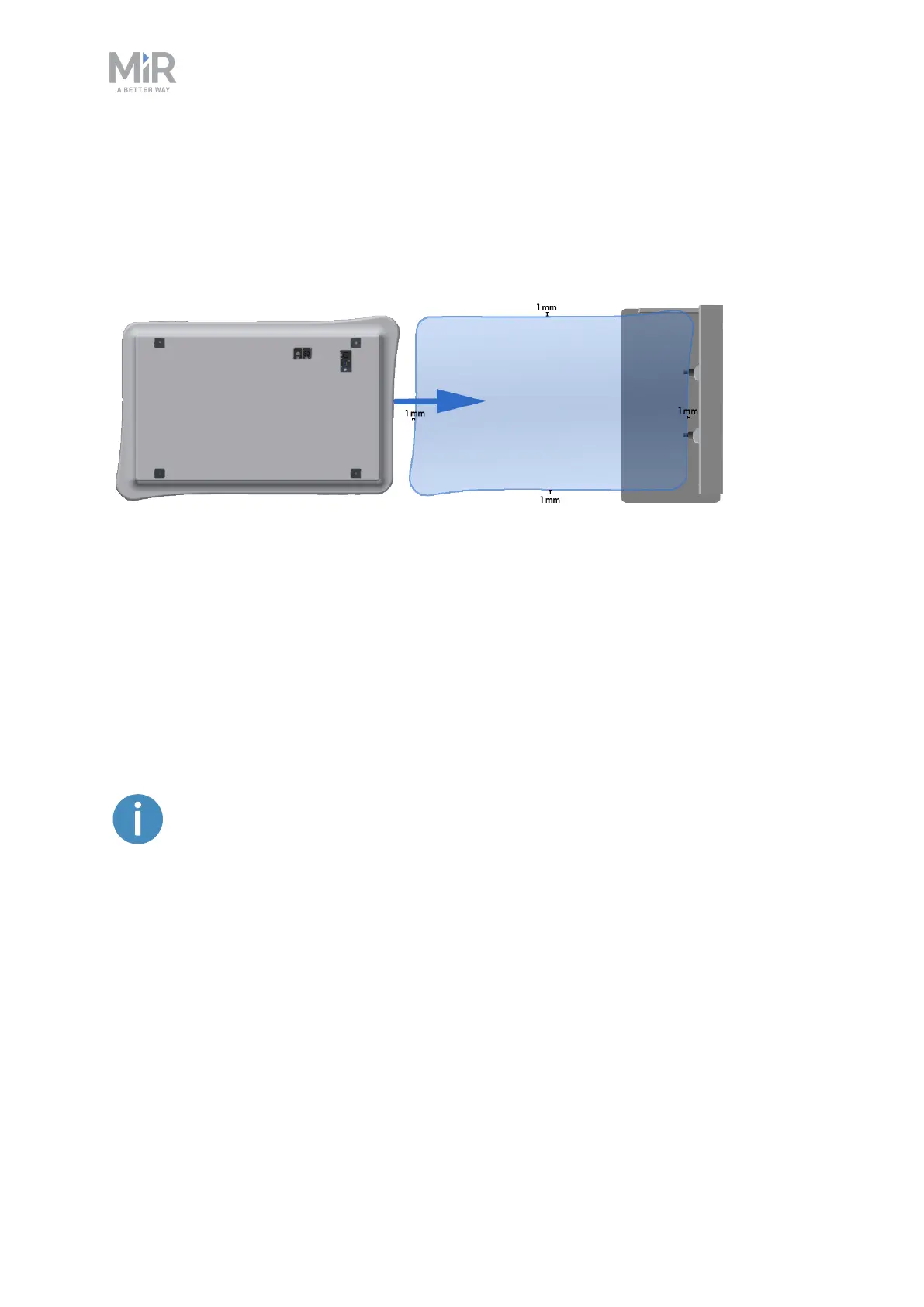

MiR Precision Docking is used in cases where high precision is required. It enables a

MiR100/MiR200 to dock with a precision of ±1 mm left and right, and ±1 mm in depth. This

is illustrated in Figure 3.1.

Figure 3.1. A MiR robot can dock with a precision of less than 1 mm in horizontal directions when using MiR

Precision Docking.

The product consists of two parts: a set of precision holes mounted in the robot, known as

the robot part; and a VL-marker station with a pair of precision pins. When the robot docks,

it aligns the precision holes and pins to guarantee a precise docking. When the pins are

inserted in the holes, the robot locks onto the docking station to ensure the robot is not

displaced. When the robot needs to move to another position, the robot releases the pins,

enabling the robot to undock. The pins are also released if you use Manual control to move

the robot from the station.

You can also release the pins manually by pressing the Manual pin release

button located on the side of the robot.

The robot part is already installed in MiR100/MiR200. The station can be placed anywhere

that is accessible by the robot. It is important that free space is available around the station

to ensure the robot is able to dock safely.

3.1 External parts

Figure 3.2 identifies the parts of the robot that are unique to a MiR100/MiR200 robot

installed with MiR Precision Docking.

Loading...

Loading...