8

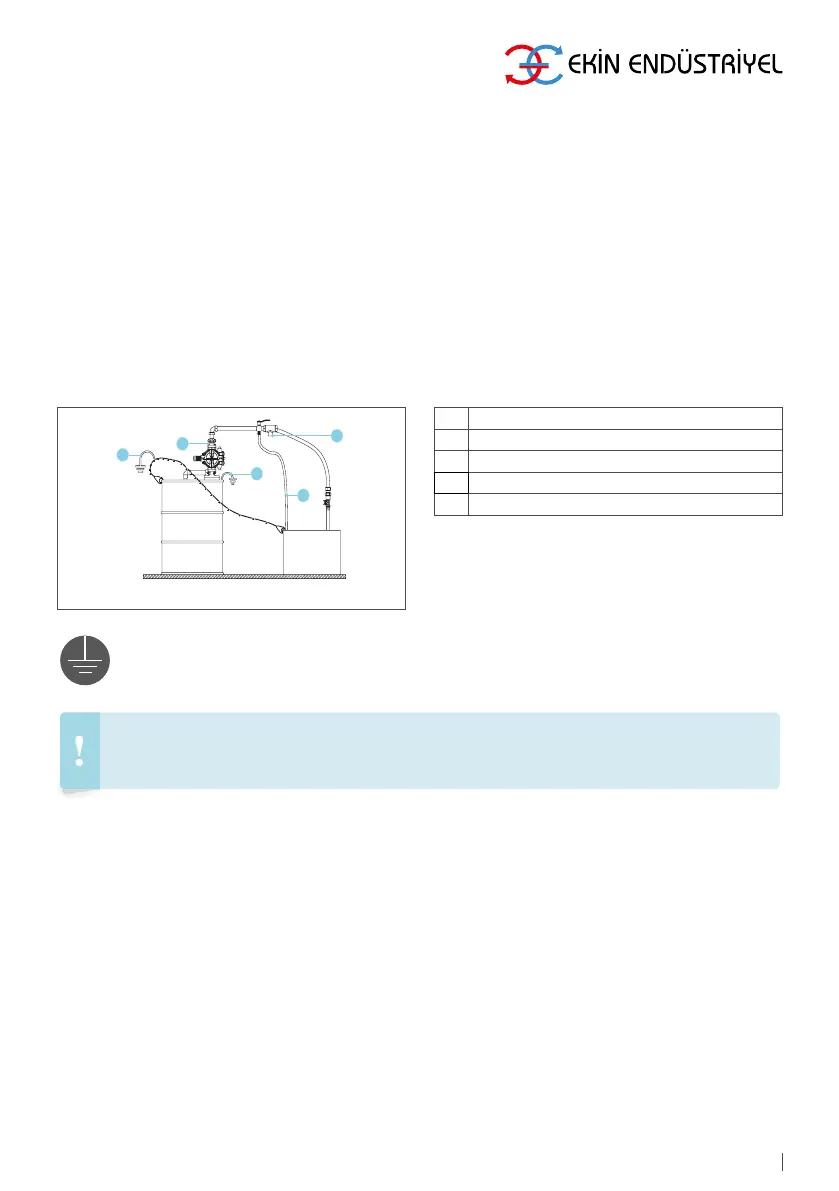

Ground the diaphragm pump as shown below (page 8, gure 4). Surfaces that contact with uid

in the diaphragm pump should be grounded with metal stainless wire or power cable. Suction

and compression lines should be selected from the conductive materials while transferring

inammable and explosive uids. Grounding should be made just like in the pump in two lines. Do

not use nonconductive polypropylene and PVDF bodies in inammable and explosive uid

transfer. All equipment should be grounded to prevent sparks and res that may occur due to

static electricity and to decrease risks (pump, air and uid hoses, air compressor, inammable

matter buckets, uid supply container and etc.).

• Clips should be also grounded in clip type pumps.

• Fluid pressures should be less than 2x10

12

ohm centimeters in the diaphragm pumps.

Grounding of The Pump

A Pump

B Fluid Relief Valve

C Fluid Drain Line

D Grounding Strip (Grounding Screw)

E Container Grounding Cable

Washing and Cleaning The Pump

The diaphragm pump to be installed was exposed to pressure and leakage test with water by the

Ekin Endüstriyel. If any food product will be transferred with this pump or any uid transfer to

react will be made in case of contact with water, wash the pump with a compatible solvent or

compatible uid before commissioning the pump.

Diaphragm pump should be grounded against the static electricity.

Grounding cable section should be minimum 6,5 mm in exproof pumps. Besides, HFFR (Halogen free ame

retardant) cable should be used instead of standard cable. Place to which cable to be used in the pump will be

connected was stated with a special mark on the pump. The customer supplies this cable.

Commissioning of The Pump

Connection of the diaphragm pump is very easy. The uid is absorbed inside the pump from the

bottom inlet pipe having suction nozzle and transfer uid is pressed to outside from the pump

from top outlet pipe having pressure nozzle. Diaphragm pumps have a knocking ow. One of the

ways to prevent knocking ow is to install exible hose before inlet and outlet line of the pump in

installation place. Another ow regulation is to place damping volume (balance tank, tranquilizer)

before the compression line.

Figure 4

Loading...

Loading...