36

Install the gasket, air inlet cover and bolts. Connect the air inlet to the pump. The pump is ready

for use.

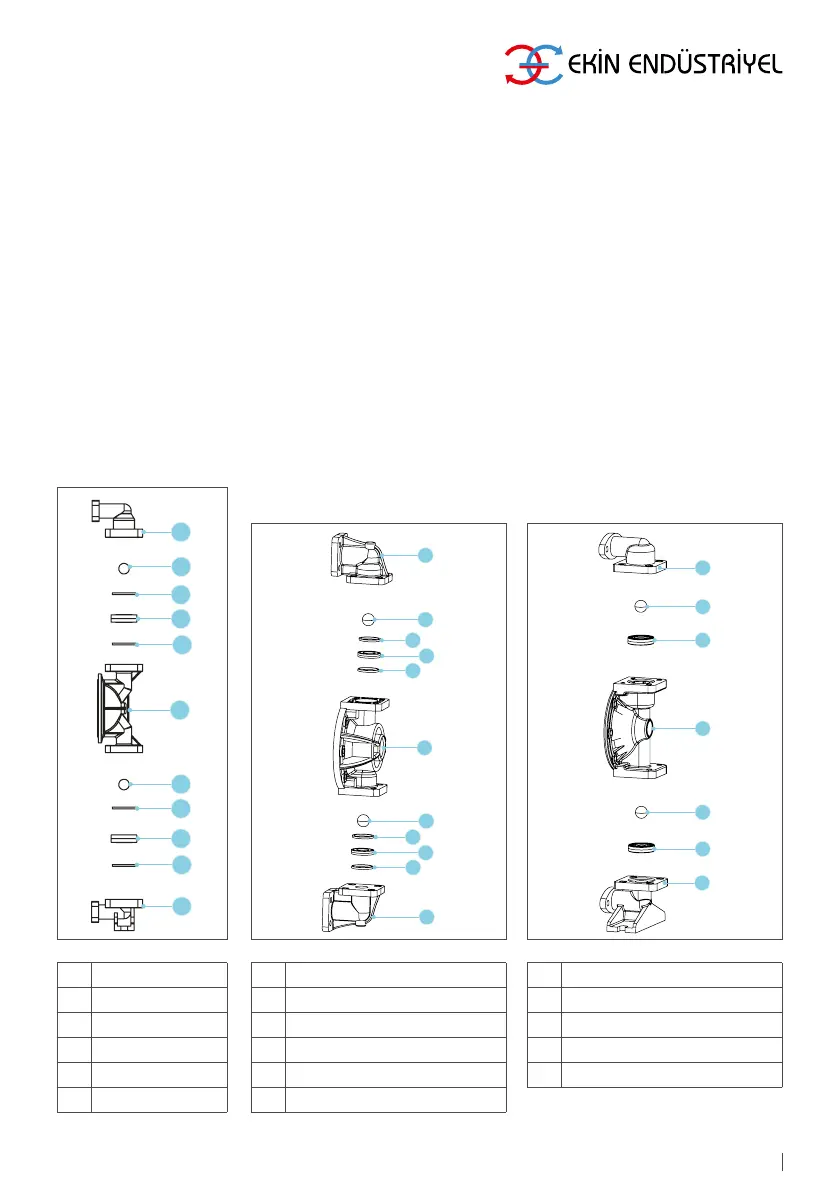

Plastic and Metallic Body Pump Check Valve Maintenance

Close suction and discharge line of the pumps before starting check valve maintenance. Cut

pressure air inlet, and relieve the pressure in the pump. Drain the uid in the pump.

Remove the bolts in uid inlet and uid outlet lines in section shown in the gure to access the

ball valve. Check spherical surfaces of the balls for wearing, abrasion or cuts.

Ball slots should be controlled in terms of potential materials adherent on internal and external

surfaces for cut and wear. Ball surfaces should be placed completely on surfaces of the ball

seats. This affects the efciency of the pump. Replace worn and damaged parts when necessary.

Regroup check valve parts.

2A

5

6

5

1A

6A

6

4

6A

6A

6A

1A Elbow, Suction

6A Gasket, Ball, Seat

6 Ball Seat

5 Ball, Check

4 Chamber Outher

2A Elbow, Discharge

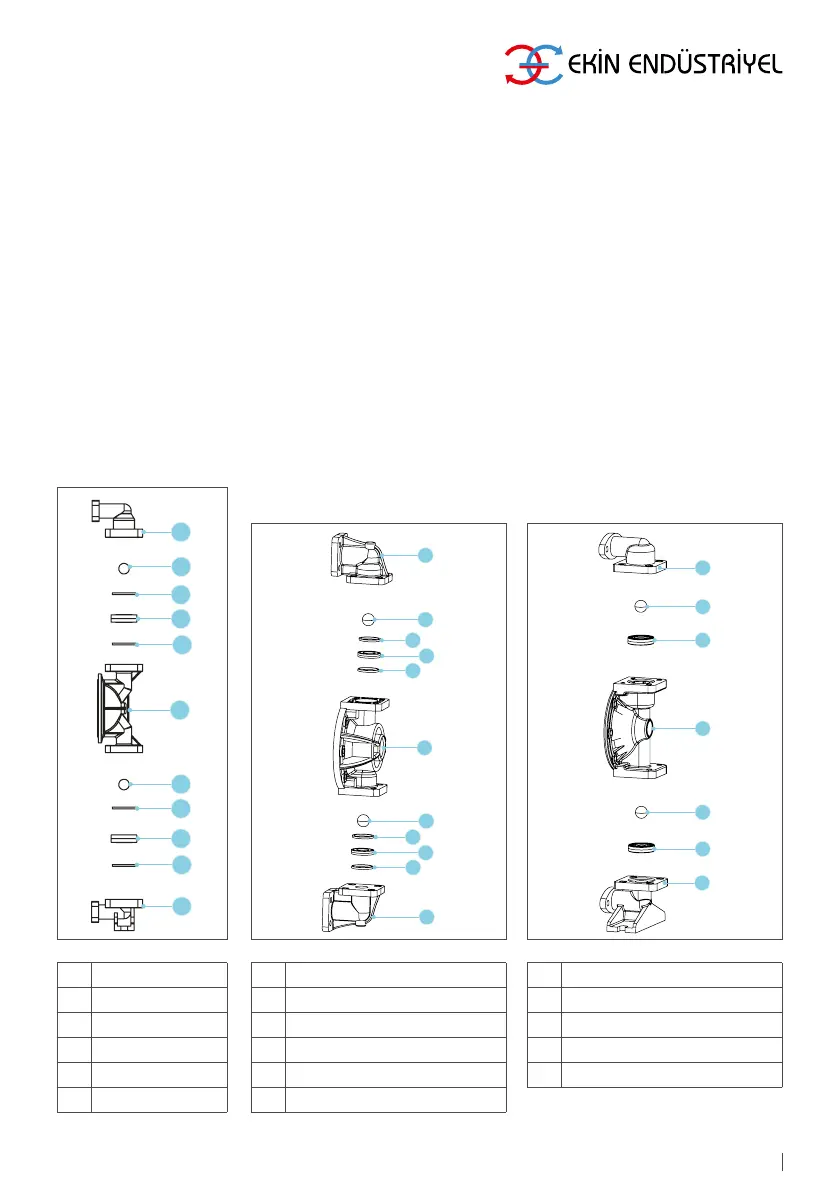

MIT 160 MIT 550

Plastic Body Metal Body

2A

6A

6A

5

4

6

6A

6A

5

6

1A

2A

1A

4

6

6

5

5

1A Elbow, Suction

6A Gasket, Ball, Seat

6 Ball Seat

5 Ball, Check

4 Chamber Outher

2A Elbow, Discharge

1A Elbow, Suction

6 Ball Seat

5 Ball, Check

4 Chamber Outher

2A Elbow, Discharge

Loading...

Loading...