39

MIT 160 (Plastic Body)

Problems That May Occur In The Pump and Their Solutions

If pressure air comes to the pump

and pump does not operate, air directly

gets out from the exhaust.

The case piston may be stuck. Air coming to

the pump should be clean.

Remove and clean air valve.

If the pump operates but does not suction.

Parts may be pressurized between ball and

ball slot.

Clean ball valves expecially in suction

section.

If the pumps operates but uid capacity

is low.

Air coming from the compressor may be

less. Ball and ball slots may be abraded.

Control and if necessary

replace with the new ones.

If pump transfer is unbalanced. Pilot valve may be malfunctioned. Replace with the new one.

If there are bubbles in uid coming

from the pump.

Suction line may be loose. Compress.

Diaphragm may be perforated. Replace.

Diaphragm retainers may be loose. Compress.

If liquid comes from the exhaust air.

Diaphragm may be perforated. Replace.

Diaphragm retainers may be loose. Compress.

Compressor air is excessively moist. Clean compressor tank.

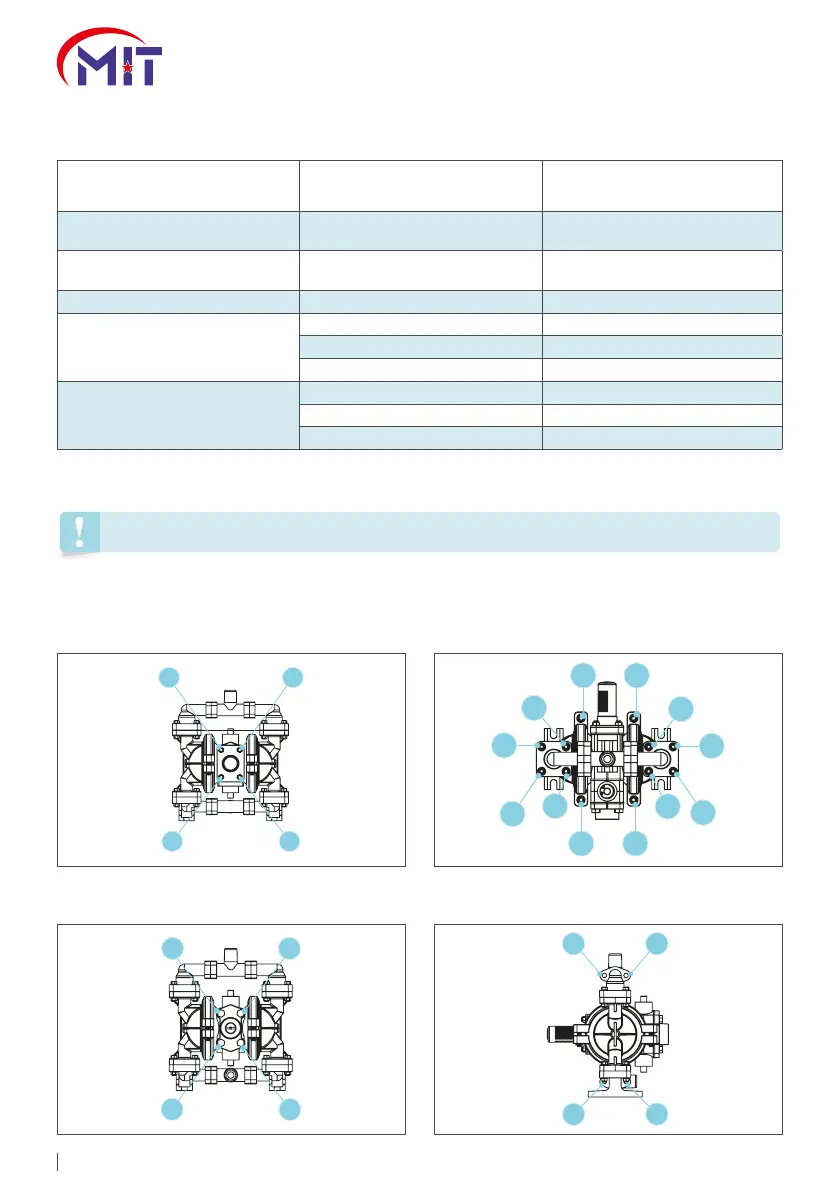

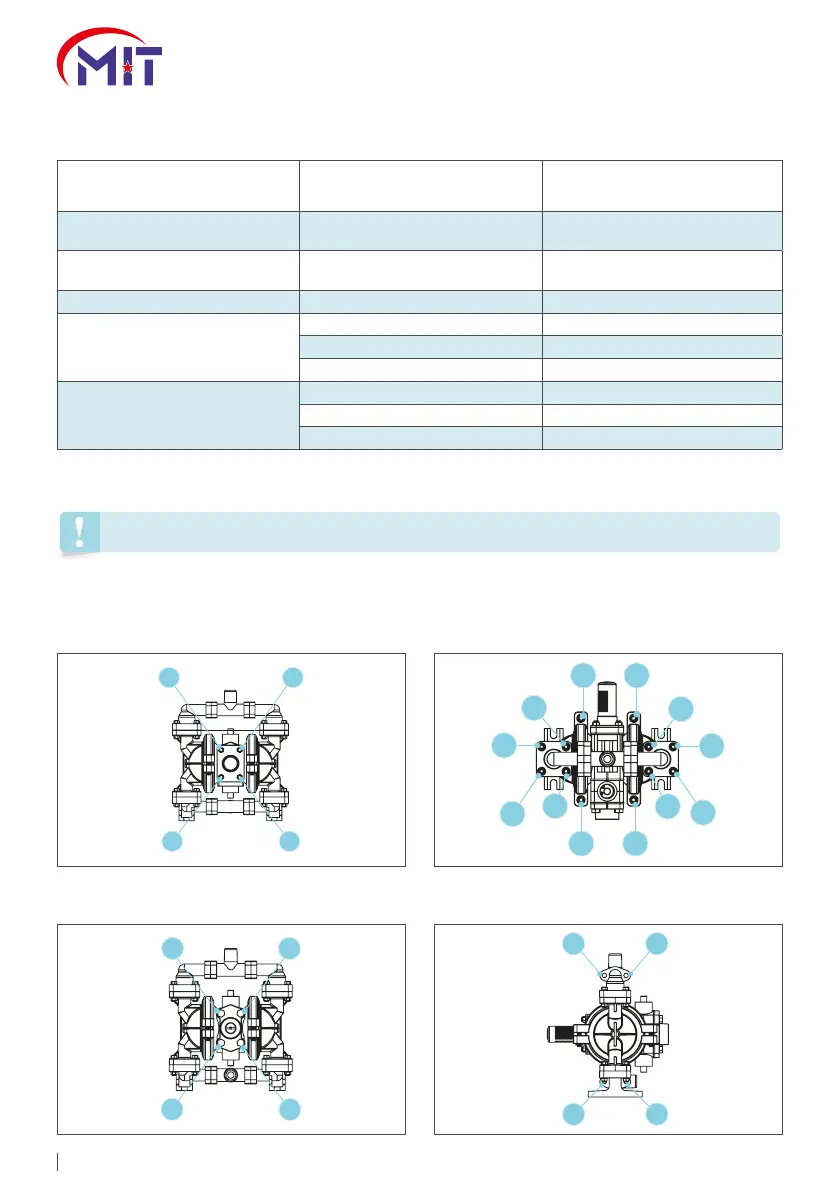

Torque Line In Plastic and Aluminium Body Pumps

Air Valve Cover (6N.m_9N.m)

Pilot Valve Cover (6N.m_9N.m)

T Elbow Part (6N.m_10N.m)

Right Left Fluid Cover (6N.m_10N.m)

2014

1913

23

22

24

21

16

18

17

15

10

12

11

9

Civataları aşağıda belirtilen torklarla sıkınız. Civata sıkma sırasına mutlaka uyulmalıdır.

Loading...

Loading...