4

INSTALLATION

General Information

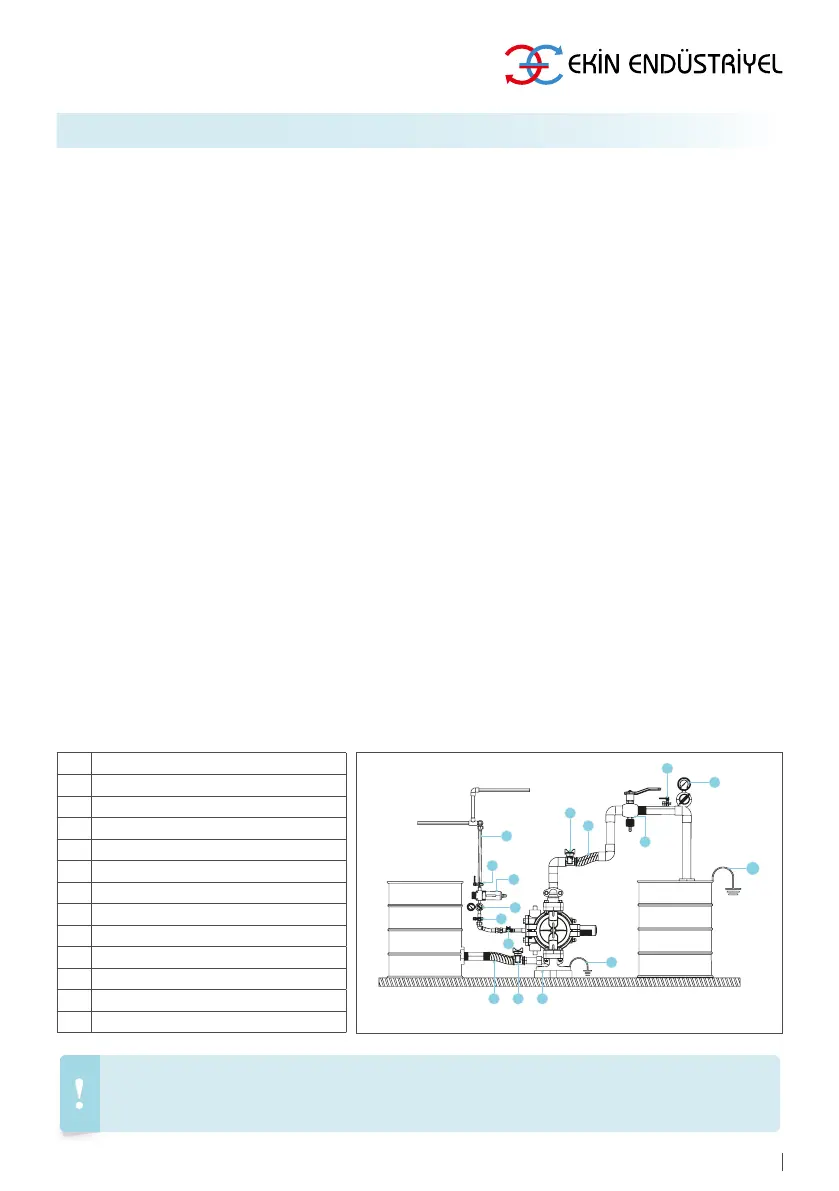

Installation of the diaphragm pump is easy. However, if installation characteristics recommended

by the manufacturer company are considered, working life of the pump shall be long and have

high efciency. (see page 4, gure 1). It should be paid attention that there is no leak and ow

from thread connections when air or uid connection components (hoses, pipes, ttings material

and etc.) are interconnected while installing the diaphragm pump. All connection components

should be pressurized well. If necessary, uid seal should be used.

• All bolt and nut connections should be controlled before installing the diaphragm pump and

it necessary it should be re-tightened. There may be loosening in these connections due to

vibrations that the pump suffered during carrying.

• If there is pressure difference more than 25% between air pressure entering in the diaphragm

pump and outgoing uid pressure, the pump operates inefciently. Transferred uid is very

dense. This situation may be prevented by increasing weights of balls used as check valve or

by using stainless steel marbles.

• Rubber wedge should be placed under pump stands in a place where installation is made

while installing the diaphragm pump. This is recommended by the manufacturer company.

Rubber wedge decreases tensions to pump, prevents dissolution of bolts from vibration and

also prevents material fatigue.

• Diaphragm pump installation should be made to uid to be transferred at a close distance as

far as possible.

• Suction line length and ttings number should be kept at a minimum during installation.

• Diameter of suction line of the installed pump should not be decreased to smaller diameters.

• If pipe line is not exible in a place where diaphragm pump was installed, exible hose should

be positioned between pipe line and pump.

3

12

4

9

5

2

4

3

3 6

11

13

7

10

8

7

The following (Figure 1) installation type is to give user company enlightening information about how installation

should be made and to guide. Consult to Ekin Endüstriyel or authorized dealer for more information and document.

444 35 46 (EKIN)

1 Aodd Pump

2 Fluid Relief Valve

3 Fluid Shutoff Valve

4 Flexible Fluid Outlet Loine

5 Manometer

6 Rubber Wedge

7 Ball Valve (To Control Air Flow)

8 Manometer (Air Pressure Measurement)

9 Air Filter / Regulator Assembly

10 Air Supply Line

11 Pump Ground Wire

12 Grounding Wire

13 Fluid Drain Valve

Figure 1

Loading...

Loading...