35

If the nose pin is damaged while operating under high pressure, and the problem insists when the

pin is replaced, replace with a pin with larger cross section.

Close suction and discharge line of the pump before starting nose pin maintenance. Cut pressure

air inlet, and relieve the pressure in the pump. Drain the uid in the pump.

See pump installation diagrams. Remove four bolts by using a wrench or socket. Remove air inlet

cover and air inlet gasket. Pilot valve group can be removed for control and maintenance.

Check the nose pins. Refer to the gure. Nose pins can be accessed through the opening among

the pilot valve group. Remove the pins from the bushings on both sides of the pins. Check o-rings

for dirt, cut and wear. Replace the o-rings when necessary. Apply a thin layer of grease on each

o-ring, then place the pins on bushings. Push the pin forward. Pay attention that pilot valve ends

are adjusted between piston pins while reinstalling pilot valve group to intermediate space gap.

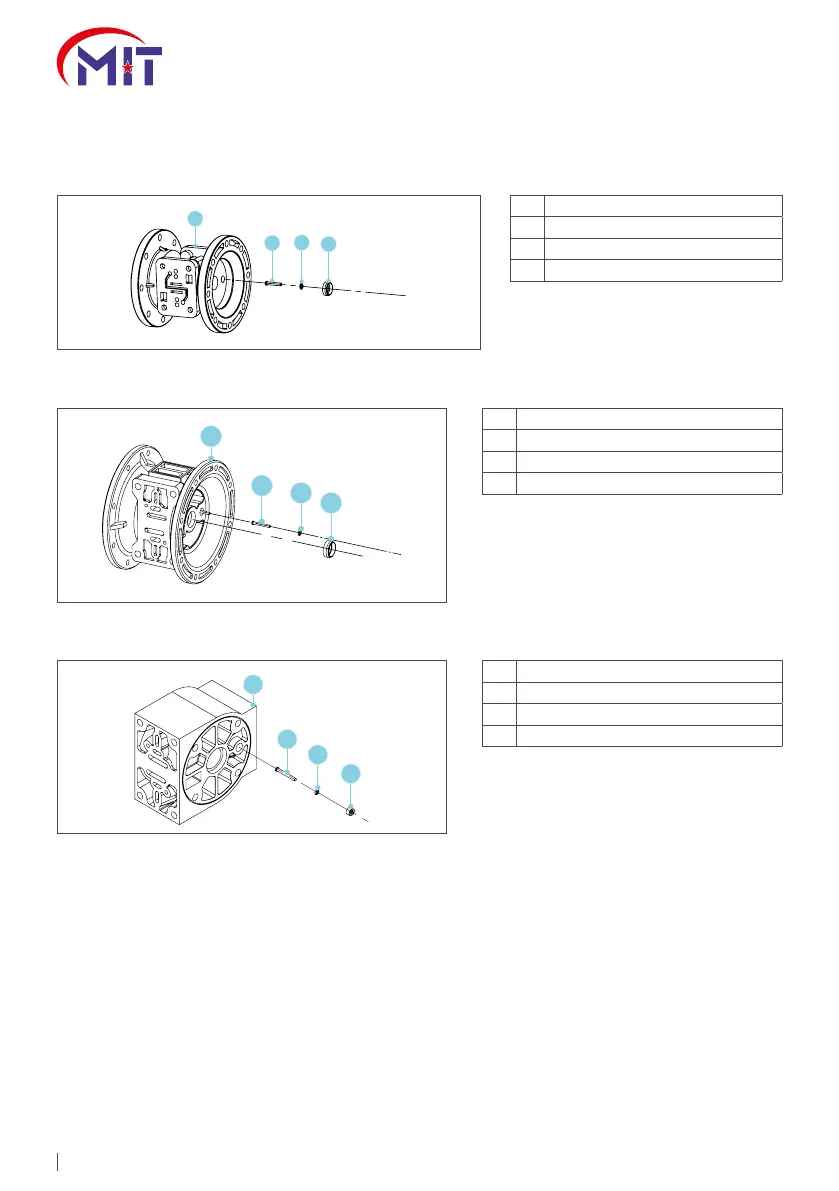

3 Main Body

11 Plunger, Actuator

19 O-Ring, For Pin

21 Bushing, Plunger

Actuator Plunger Maintenance

MIT 550

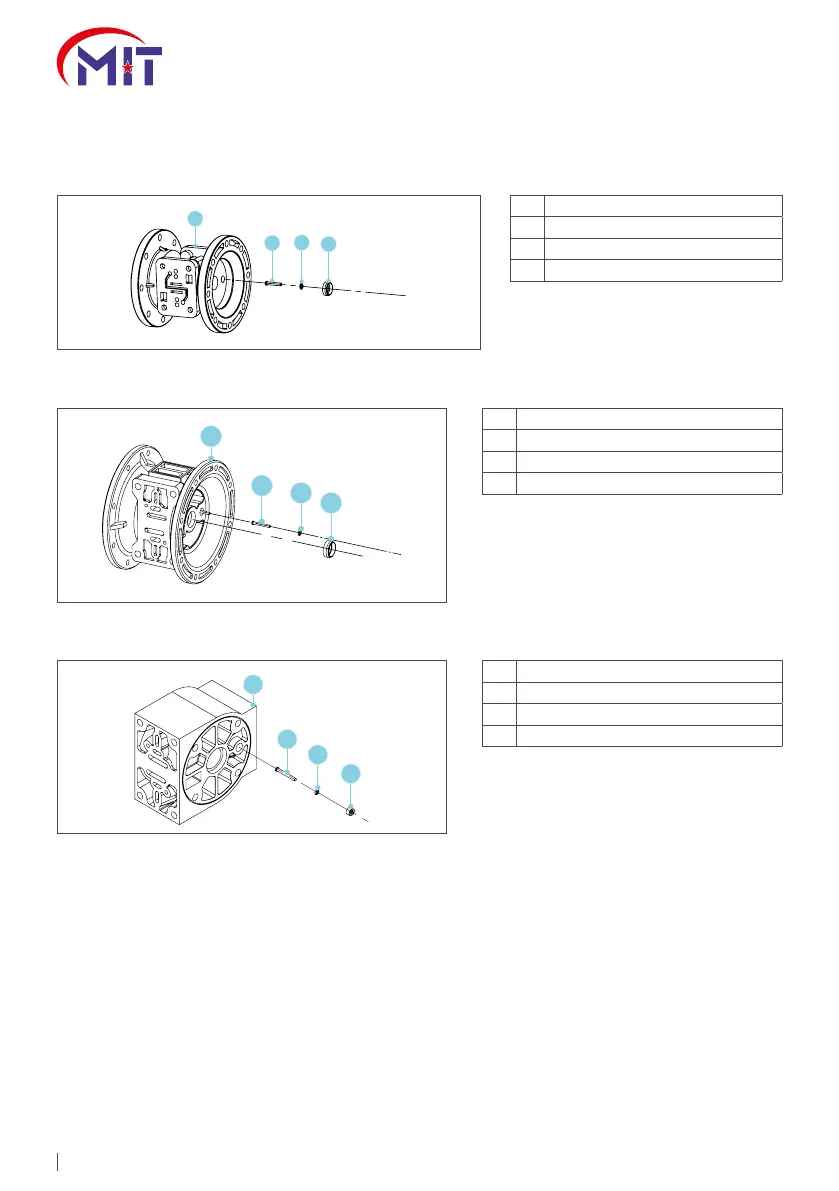

MIT 1500

MIT 4000 / MIT 5600 / MIT 8900

3

16

11

19

1 Main Body

2 Plunger, Actuator

3 O-Ring, For Pin

4 Bushing, Plunger

3

19

16

11

3 Main Body

19 Plunger, Actuator

16 O-Ring, For Pin

11 Bushing, Plunger

Loading...

Loading...