4MELFA-BASIC V

Detailed explanation of Robot Status Variable 4-365

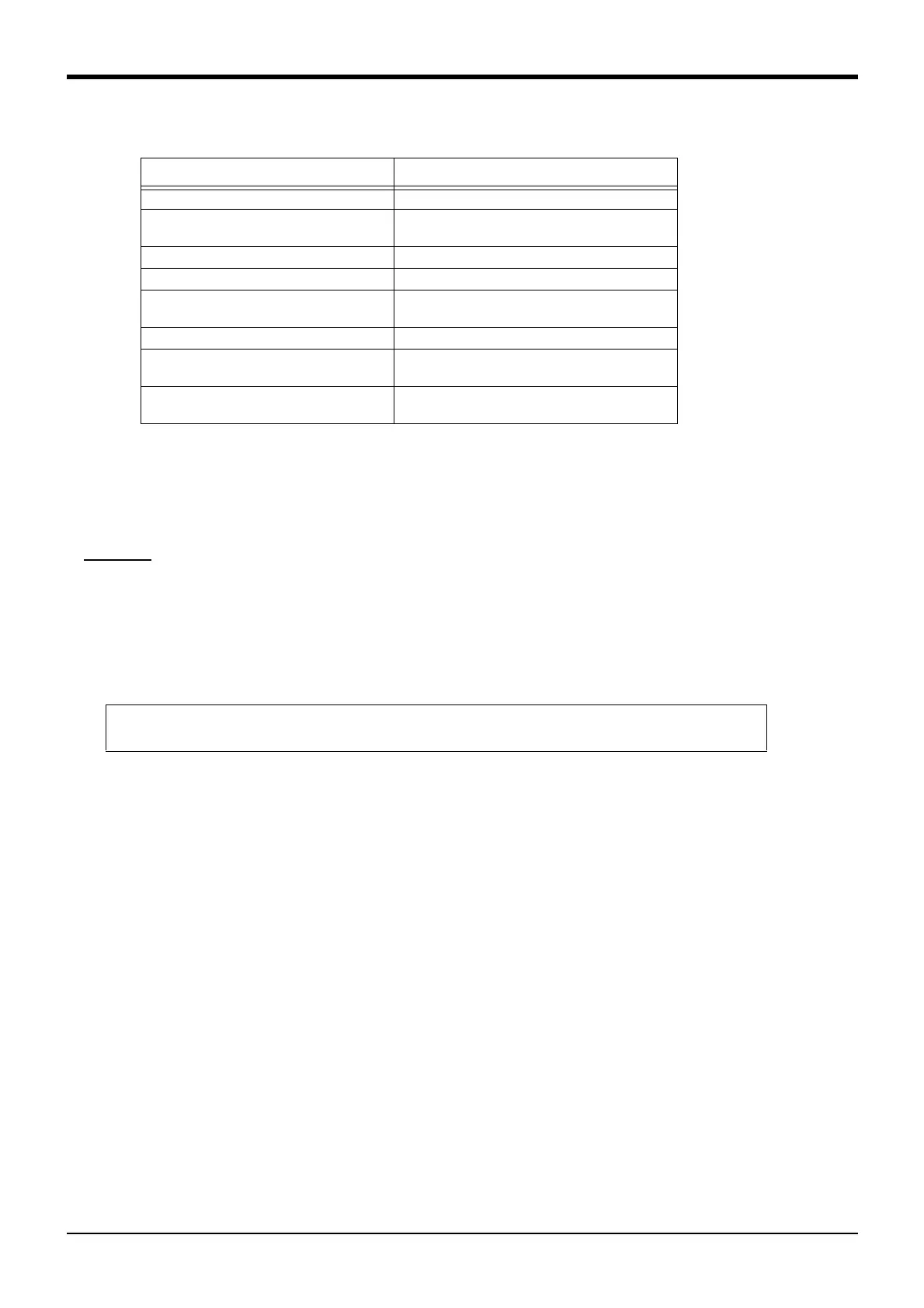

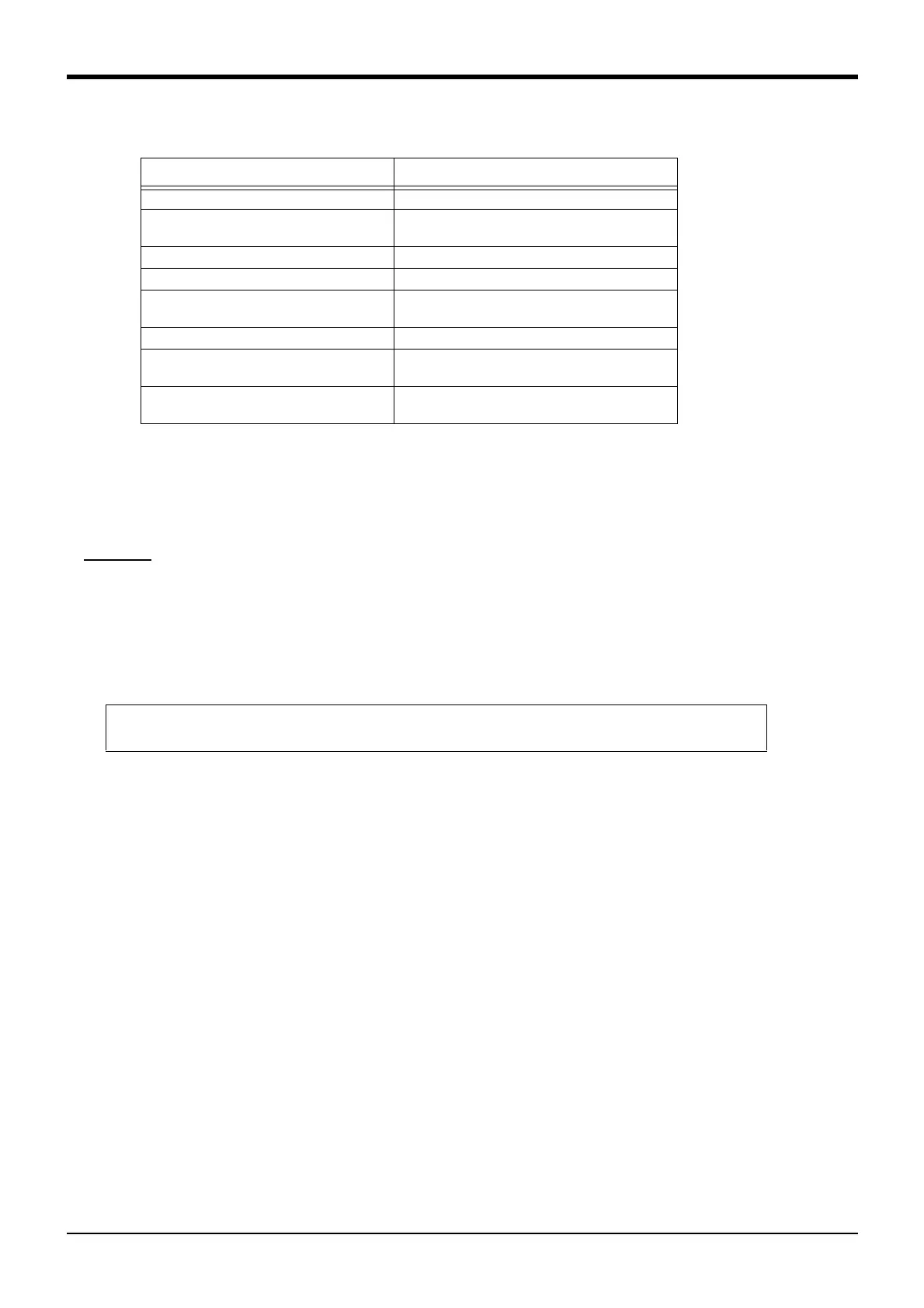

(4) M_SplVar returns the value according to the states shown in Table 4-33.

Table 4-33: Value returned by M_SplVar

(5) A random value between 0 and 32767 can be set by writing to M_SplVar. That value is held until the

value is changed with spline interpolation or other operations/processes.

M_Svo

[Function]

Returns the current status of the servo power supply.

1: Servo power ON

0: Servo power OFF

[Format]

[Terminology]

<Numeric Variable> Specifies the numerical variable to assign.

<Mechanism Number> Enter the mechanism number. 1 to 3, If the argument is omitted, 1 is set as the

default value.

[Reference Program]

1 M1=M_Svo(1) ' M1 will contain the current status of the servo power supply.

[Explanation]

(1) The status of the robot's servo can be checked.

(2) This variable only reads the data.

Status Value returned by M_SplVar

Immediately after power ON 0

During spline interpolation execution Value corresponding to progress of spline inter-

polation (Value set in spline file)

When passing through path point set to "–1" Value at that time is continuously applied

After spline interpolation Value at end of spline interpolation

Immediately after main program’s END

command is executed

0

Immediately after program reset operation 0

Immediately after value is read into

M_SplVar

Written value

Mechanism not compatible with spline inter-

polation

0 (0 even after write is executed)

Example)<Numeric Variable>=M_Svo [(<Mechanism Number>)]

Loading...

Loading...