20

1.Checkallconnectionsincludingfactoryttedonesaretight.

2.Insulatepipeworkbetweenhydroboxandoutdoorunit.

3.Thoroughlycleanandush,systemofalldebris.(Referto4.2intheinstallationmanual.)

4.Fillprimaryheatingcircuitwithwaterandsuitableanti-freezeandinhibitorasnecessary.Alwaysuseallingloopwithdoublecheckvalvewhenllingthe

primarycircuittoavoidbackowcontaminationofwatersupply.

• Anti-freezeshouldalwaysbeusedforpackagesystems.Itistheresponsibilityoftheinstallertodecideifanti-freezesolutionshouldbeusedinsplitsystems

dependingoneachsite’sconditions.Corrosioninhibitorshouldbeusedinbothsplitandpackagesystems.

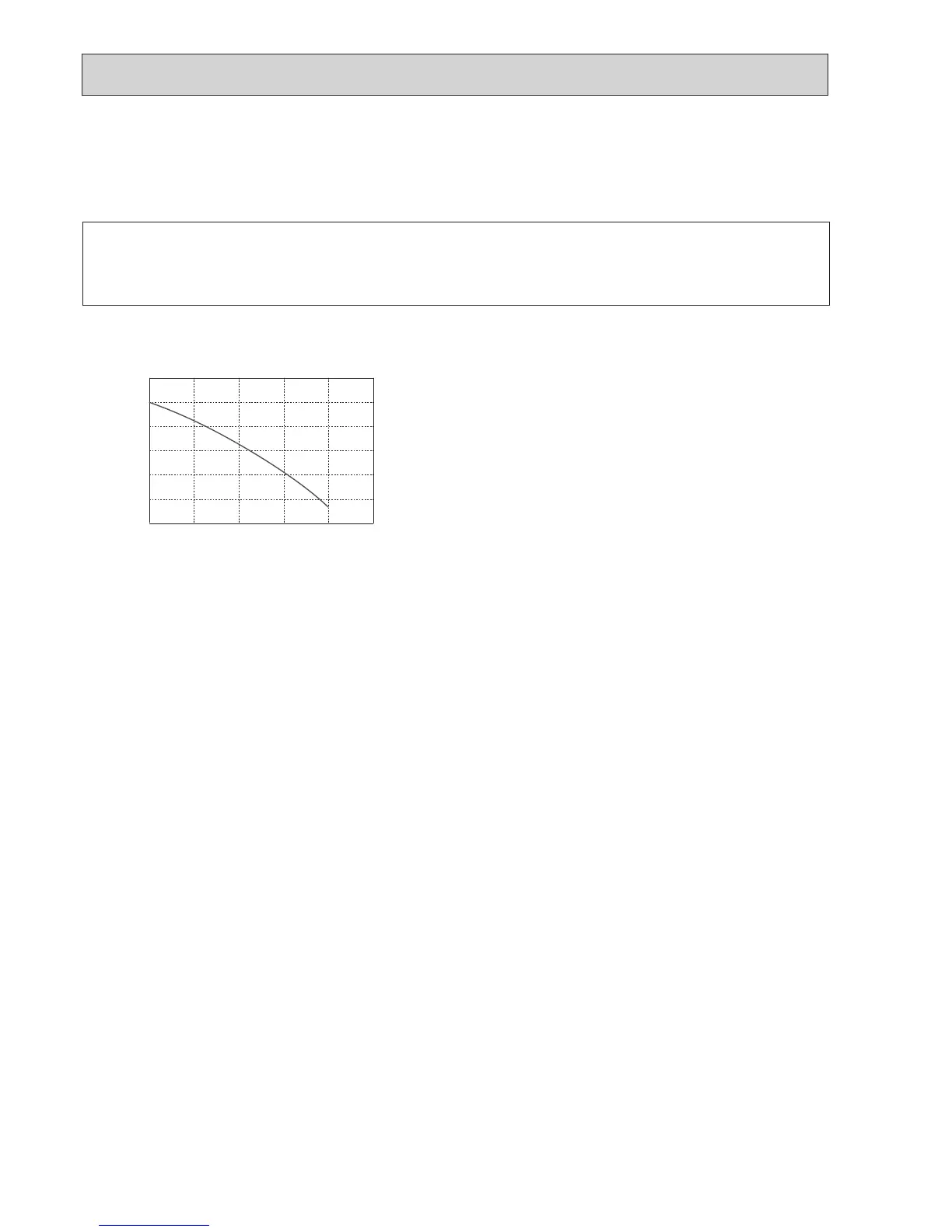

Figurebelowshowsfreezingtemperatureagainstanti-freezeconcentration.ThisgureisanexampleforFERNOXALPHI-11.Forotheranti-freeze,pleaserefer

to relevant manual.

• Whenconnectingmetalpipesofdifferentmaterialsinsulatethejointstopreventacorrosivereactiontakingplacewhichwilldamagethepipework.

5.Checkforleaks.Ifleaksarefound,retightenthescrewsontheconnections.

6.Pressurisesystemto1bar.

7.Releasealltrappedairusingairventsduringandfollowingheatingperiod.

8.Topupwithwaterasnecessary.(Ifpressurefallsbelow1bar)

Filling the System (Primary Circuit)

Draining the Hydrobox

WARNING: DRAINED WATER MAY BE VERY HOT

1.Beforeattemptingtodrainthehydroboxisolatefromtheelectricalsupplytopreventboosterheaterburningout.

2.Isolatehydroboxfromprimarywatercircuitanddrainwaterfromhydrobox.Useasuitableheatresistanthosetoassistintheseoperations.

3.Drainanyremainingwaterfromboosterheaterusingtteddraincockandhose,andthedrainvalveontheprimarycircuittosafelydraintheunit.

4.Afterthehydroboxisdrained,waterremainsinthefollowingcomponentparts.Drainwatercompletelybycheckingtheinsideoftheparts.

• Strainer(Removethestrainercover.)

• Pressurereliefvalve(Operatethevalve.)

0

−25

−20

−15

−10

−5

5

0

10 20 30 40 50

Freezingtemperature[°C]

Anti-freezeconcentration[%]

Loading...

Loading...