10

9

30

*1

32

32

33

34

B

30

30

35

A

Pa

11

8

27

19

16

20

18

17

21

37

3

7

13

29

36

32

34

32

4

25

5

23

6

7

24

15

14

7

12

26

3

10

29

9

30

32

32

34

34

32

B

31

A

31

32

33

Pa

11

4

25

8

27

7

19

5

15

13

16

23

20

14

6

7

24

18

17

*1

7

30

22

12

26

39

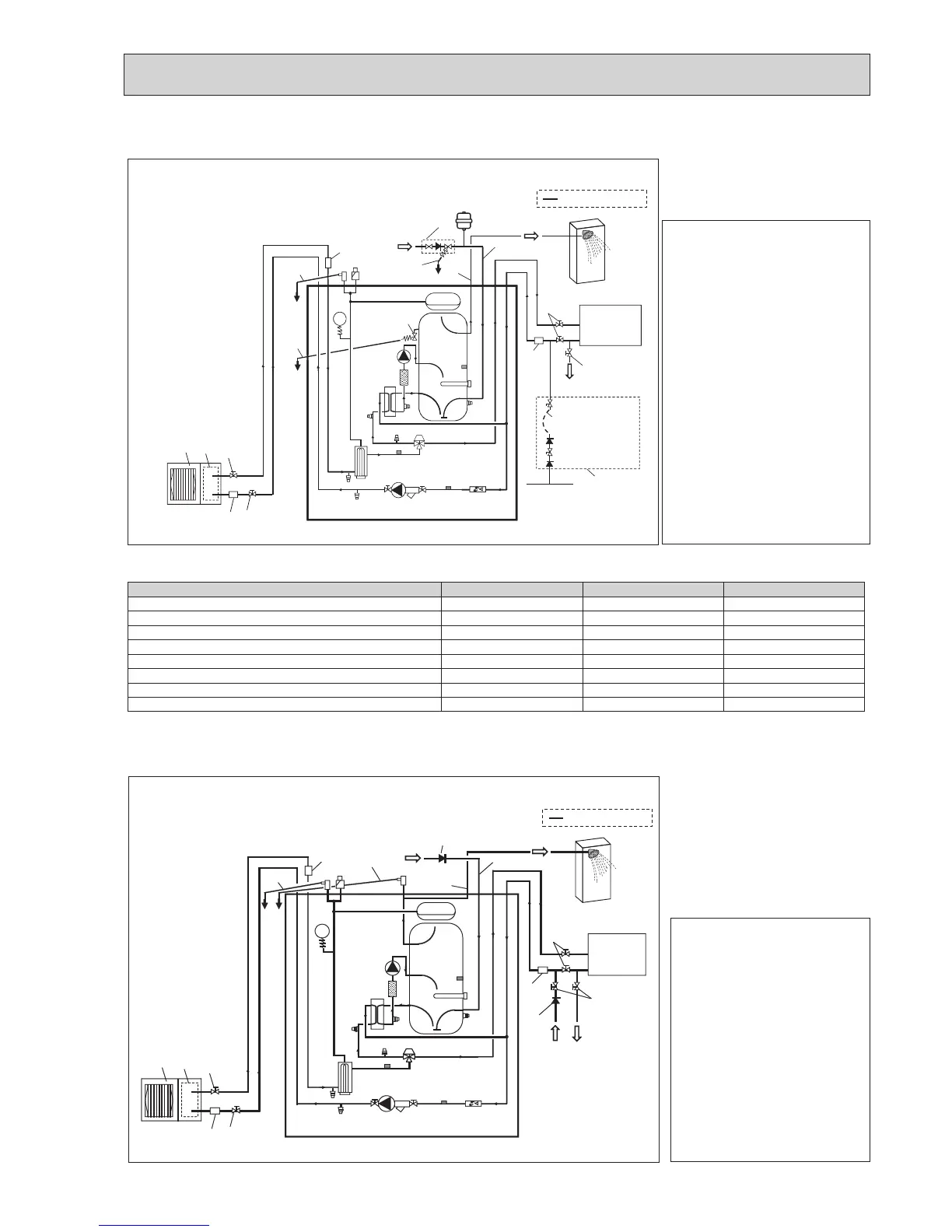

<EHPT20X-MHCW>(UKPackagedmodelsystem)<Example>

Notes:

•Toenabledrainingofthecylinderunitan

isolatingvalveshould be positioned on

boththeinlet and outlet pipework. No

valveshouldbe fittedbetweentheex-

pansion valve (item 35) and the cylinder

unit (safety matter).

•Besure to installastrainerontheinlet

pipeworktothecylinderunit.

•Suitabledrain pipework shouldbeat-

tached to all relief valves in accordance

withyourcountry’sregulations.

•Whenusingcomponentsmadefromdif-

ferentmetalsorconnectingpipesmade

ofdifferentmetalsinsulatethejointsto

preventanycorrosivereactiontaking

placewhichmaydamageanypipework.

•Fillingloop’sflexiblehosemustbere-

movedfollowingthe fillingprocedure.

Itemprovided with unitaslooseacces-

sory.

•Installthe inlet controlgroup(item35)

abovethelevel of theT&Preliefvalve

(item21).ThiswillensureDHWtank

willnotrequire drain-down to service/

maintaintheinletcontrolgroup.

Model name EHPT20X-MHCW EHST20C-MHCW EHST20D-MHCW

Maximumsupplypressuretothepressurereducingvalve 16 bar 16 bar 16 bar

Operatingpressure(Potableside) 3.5 bar 3.5 bar 3.5 bar

Expansionvesselchargesettingpressure(Potableside) 3.5 bar 3.5 bar 3.5 bar

Expansionvalvesettingpressure(Potableside) 6.0 bar 6.0 bar 6.0 bar

Immersionheaterspecication(Potableside)* 3000 W, 230 V 3000 W, 230 V 3000 W, 230 V

DHW tank capacity 200 L 200 L 200 L

Massoftheunitwhenfull 307kg 320kg 312kg

Maximumprimaryworkingpressure 2.5 bar 2.5 bar 2.5 bar

*EN60335/Type3000Wsinglephase230V50Hz,length460mm.

Use only Mitsubishi Electric service parts as a direct replacement.

<Table 8-1>

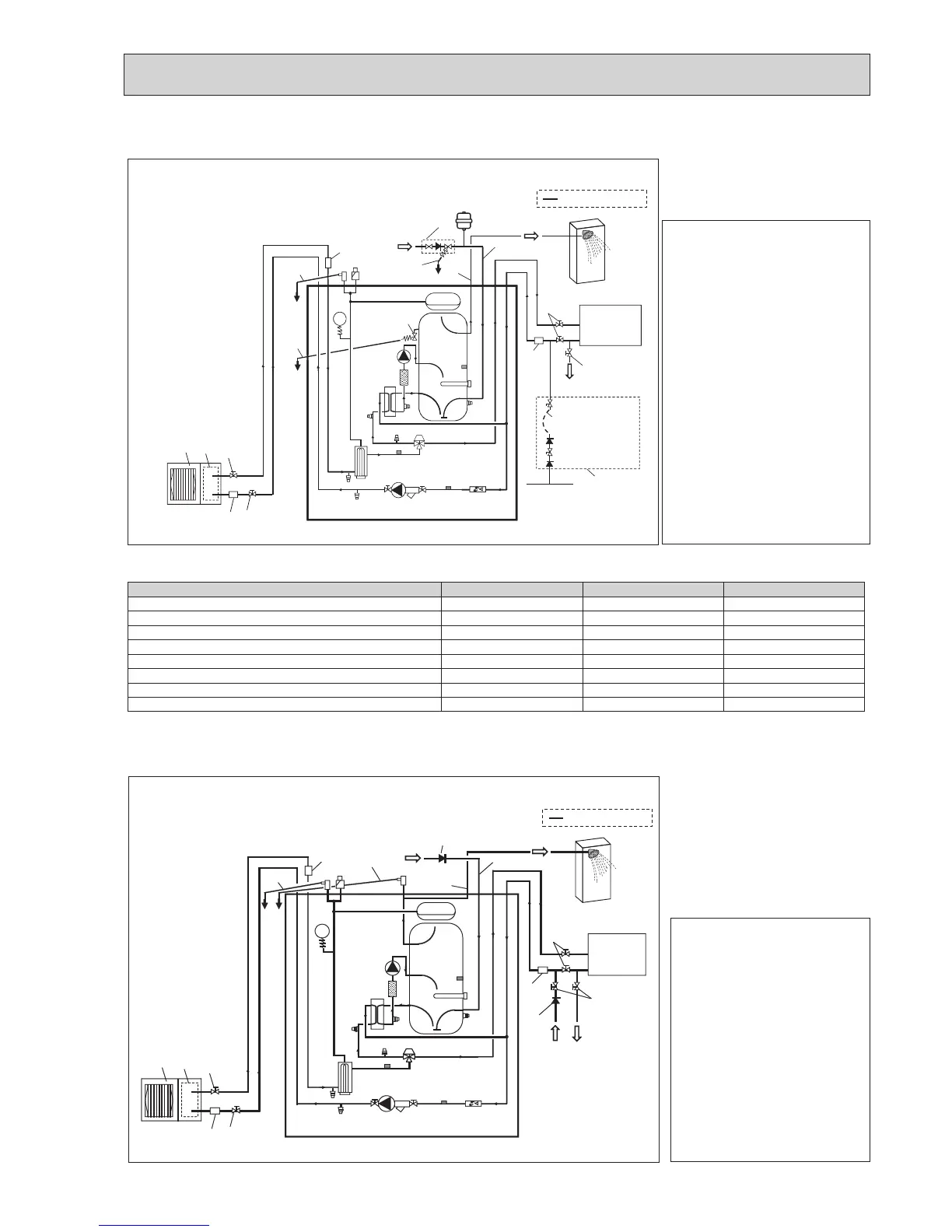

<EHPT20X-*M*C>(Packagedmodelsystem)

Notes:

•Toenabledrainingofthecylinder

unitanisolating valve should be po-

sitioned on both the inlet and outlet

pipework.

•Besuretoinstallastrainerontheinlet

pipeworktothecylinderunit.

•Suitabledrain pipework should be

attached to all relief valves in accord-

ancewithyourcountry’sregulations.

•Abackflowpreventiondevicemust

beinstalledon the cold watersupply

pipework(IEC61770)

•Whenusing components made from

differentmetalsorconnectingpipes

made of different metals insulate the

jointstopreventany corrosive reac-

tiontakingplacewhich may damage

thepipework.)

<Figure8-3>

<Figure8-4>

Cylinder unit

Drain

Drain

Drain

Drain

Coldwater

DHW

Local system

Mainwatersupply

Flexiblehose

(Temporary connection)

Cylinder unit

Drain

Drain

Coldwater

DHW

Local system

Water

supply

Water pipe

Water pipe

•Refer to <Table 4-1 and 4-2> for the part names.

*1Refertothefollowingsection[Localsystem].

Loading...

Loading...