WELDING

BASE OF BODY REPAIR

9-12

2. Silver alloy filler metal (silver solder)

Silver alloy filler metal consists of silver, copper,

zinc or cadmium, nickel, and tin, or other metals.

This filler metal is most applicable for the brazing

of steel and non-ferrous alloy other than alumin-

ium, magnesium, and others with low melting

points.

Notes with regard to brazing work

• Use a wire brush, sandpaper, file etc., to remove

any oxide film grease, dirt, etc., from the surfaces

of the panels to be brazed.

• When doing brass brazing, if the panels and the

filler metal are heated excessively, a weak iron-

copper alloy will form, which could crack easily.

Be careful not to apply excessive heat.

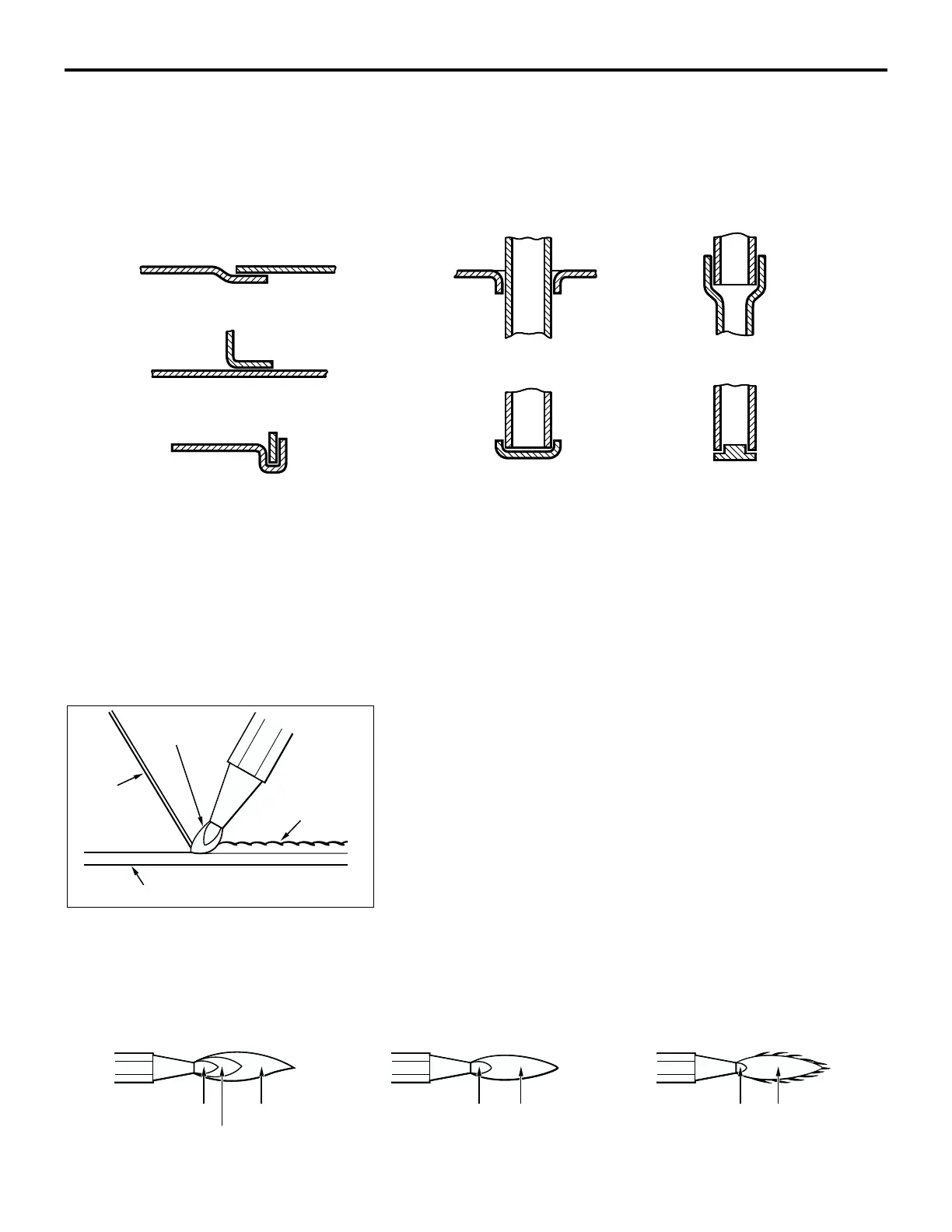

• The joint of the panels must overlap as indicated

in the illustration.

GAS WELDING

Gas welding is a method in which a high temperature flame is

used to melt both a welding rod and the base metal (panels) to

make a fused joint. Oxy-acetylene is the most common type of

gas welding. However, because of the extremely high tempera-

ture of the fused joint, the strength of the steel plate deterio-

rates, and there is a higher possibility of warping. This method,

therefore, is not very suitable for body repair.

.

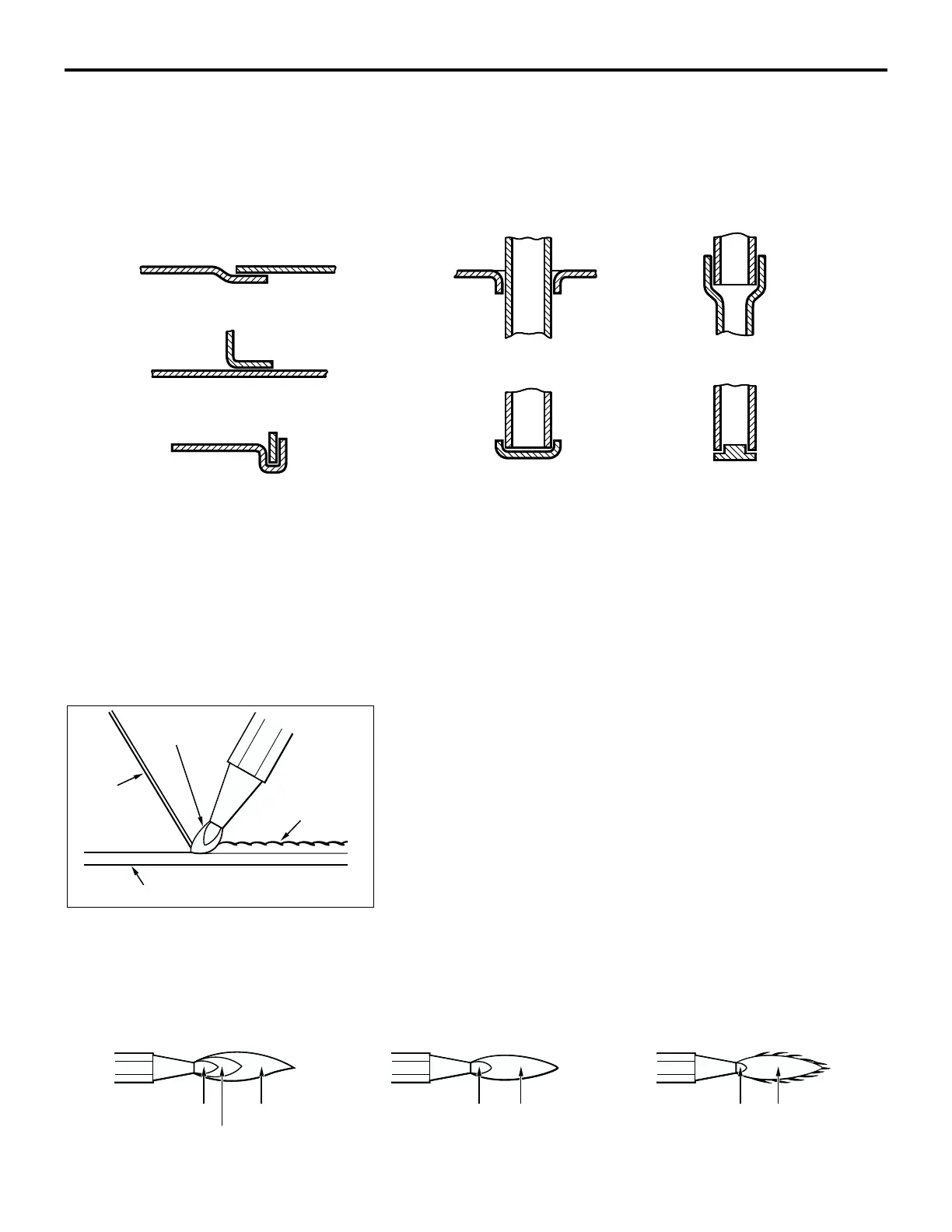

The flame in gas welding can be classified according

to the ratio of acetylene and oxygen.

AB200044AB200044

AB

EXAMPLES OF BRAZED JOINTS

AB200049

DEPOSITE

BASE METAL

WELDING

ROD

OXY-ACETYLENE

FLAME

AB

AB200050AB200050

AB

FLAME CORE OUTER FLAME

ACETYLENE CONE

FLAME CORE OUTER FLAME FLAME CORE OUTER FLAME

1. CARBURIZING FLAME 2. STANDARD FLAME 3. PEROXIDE FLAME

Loading...

Loading...