BODY REPAIR

BASE OF BODY REPAIR

9-29

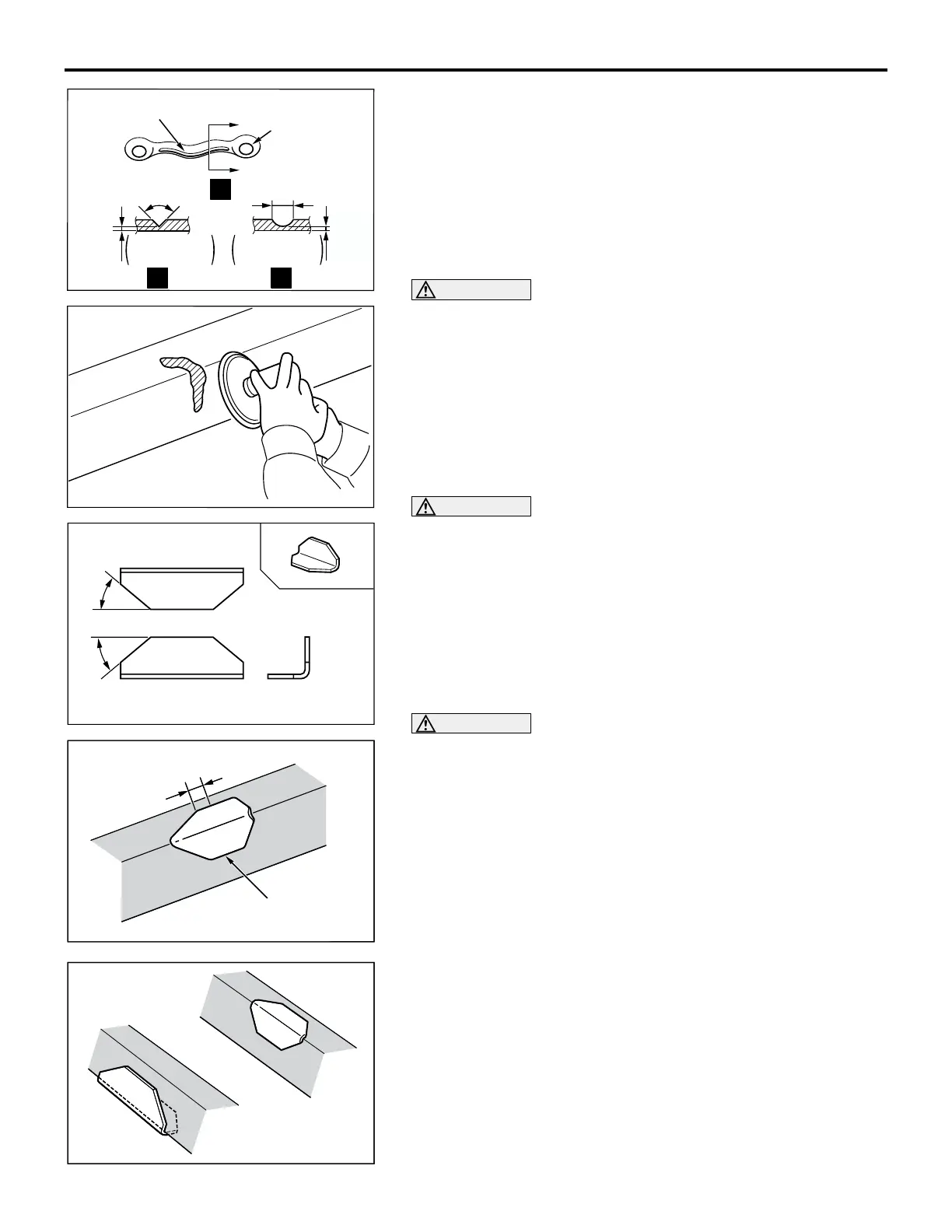

4. Use a chisel or gouging tool to open up the crack and holes,

and then fill the crack and holes by MIG welding.

CAUTION

• Gas welding should be avoided because it cause ther-

mal distortion of the frame.

• When using a grinder for finishing, be careful not to

grind the frame excessively.

5. Using a grinder for finishing after welding.

CAUTION

• The reinforcement plate should completely cover the

cracked part.

• The reinforcement plate should be the same thickness

and material as the frame.

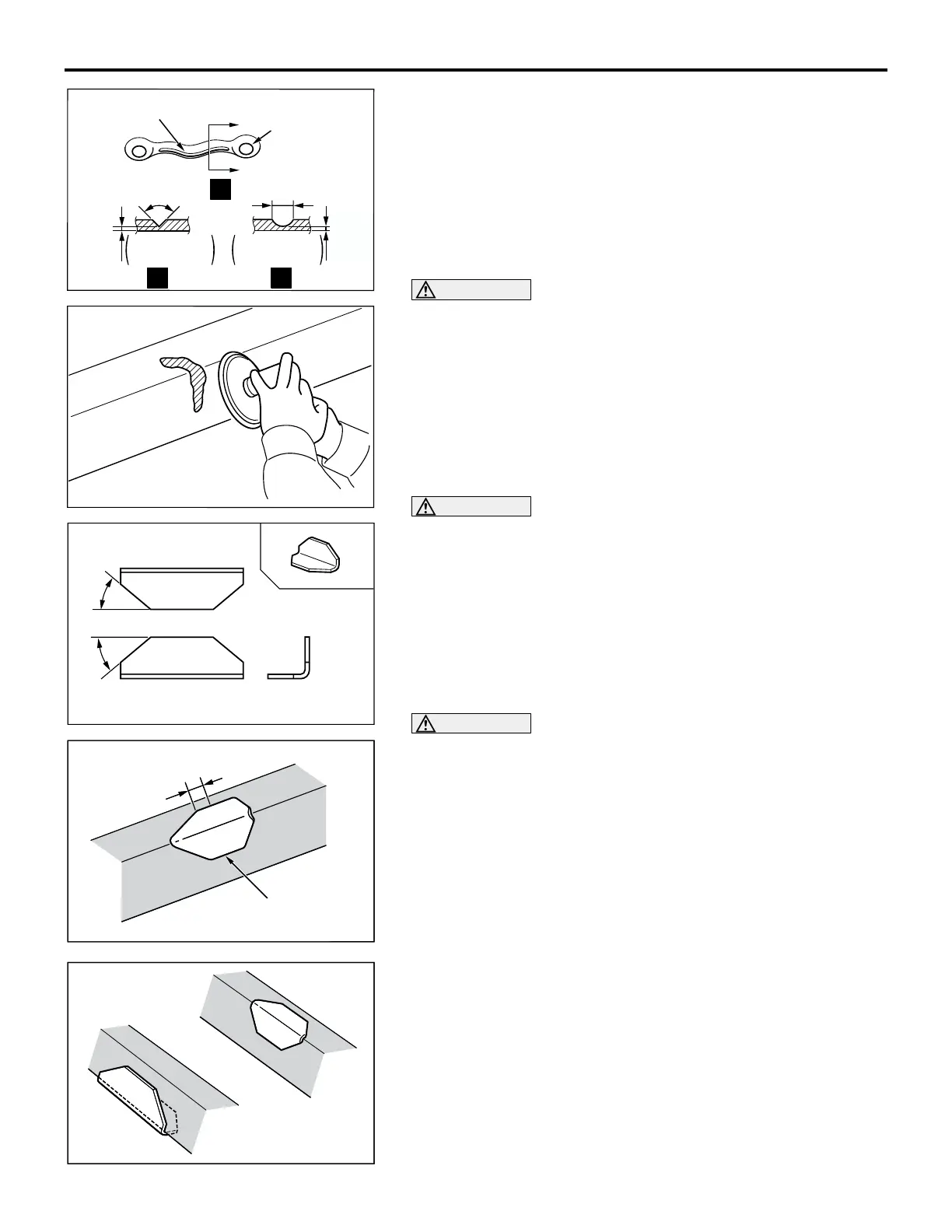

6. To avoid a concentration of stress, prepare a reinforcement

plate that has been cut to 30 - 45 degree angle at both ends.

CAUTION

Be sure that the edges of the reinforcement plate are not

near any place where a concentration of stress of the

crossmember or spring hanger installation part, etc. could

easily occur.

7. Attach the reinforcement plate to the repaired crack area by

MIG welding. In order to avoid a concentration of stress at

the time, weld the reinforcement plate at points about 10 mm

(0.4 inch) from its edges.

AB200130

AB

CRACK

CRACK-STOP

HOLE

APPROX.

8 mm (0.3 in)

APPROX.

1 mm

(0.04

in)

APPROX.

1 mm

(00.4 in)

APPROX.

90˚

IF A CHISEL

IS USED

IF A GOUGE

IS USED

A

AA

AB200131

AB

AB200132

A

A

A : 30˚ - 45˚

AB

AB200133AB200133

10 mm (0.4 in)

WELDED POINT

AB

AB200134AB200134

AB

(2)

(1)

Loading...

Loading...