BODY REPAIR

BASE OF BODY REPAIR

9-31

(2) If heat damage may occur during paint work,

remove the SRS-ECU, the air bag module,

clock spring, the front impact sensor, the side

impact sensor, and the seat belt pre-tensioner.

• SRS-ECU, air bag module, clock spring, front

impact sensor, the side impact sensor: 93 °C

(200 °F) or more

• Seat belt pre-tensioner: 90 °C (194 °F) or more

.

SECURING THE VEHICLE

If the vehicle is raised on a jack, be sure to always support it

with jack stands positioned at the specified points.

.

CLEARING THE AREA OF FLAMMABLE MATERIALS

Because of the presence of many various kinds of flammable

materials, organic solvents, etc., in the work area, there is

always the possibility of a fire or explosion. It is, therefore,

important to keep the work area as clear as possible of such

dangerous materials.

.

HANDLING ELECTRONIC PARTS AND SEMICONDUCTORS

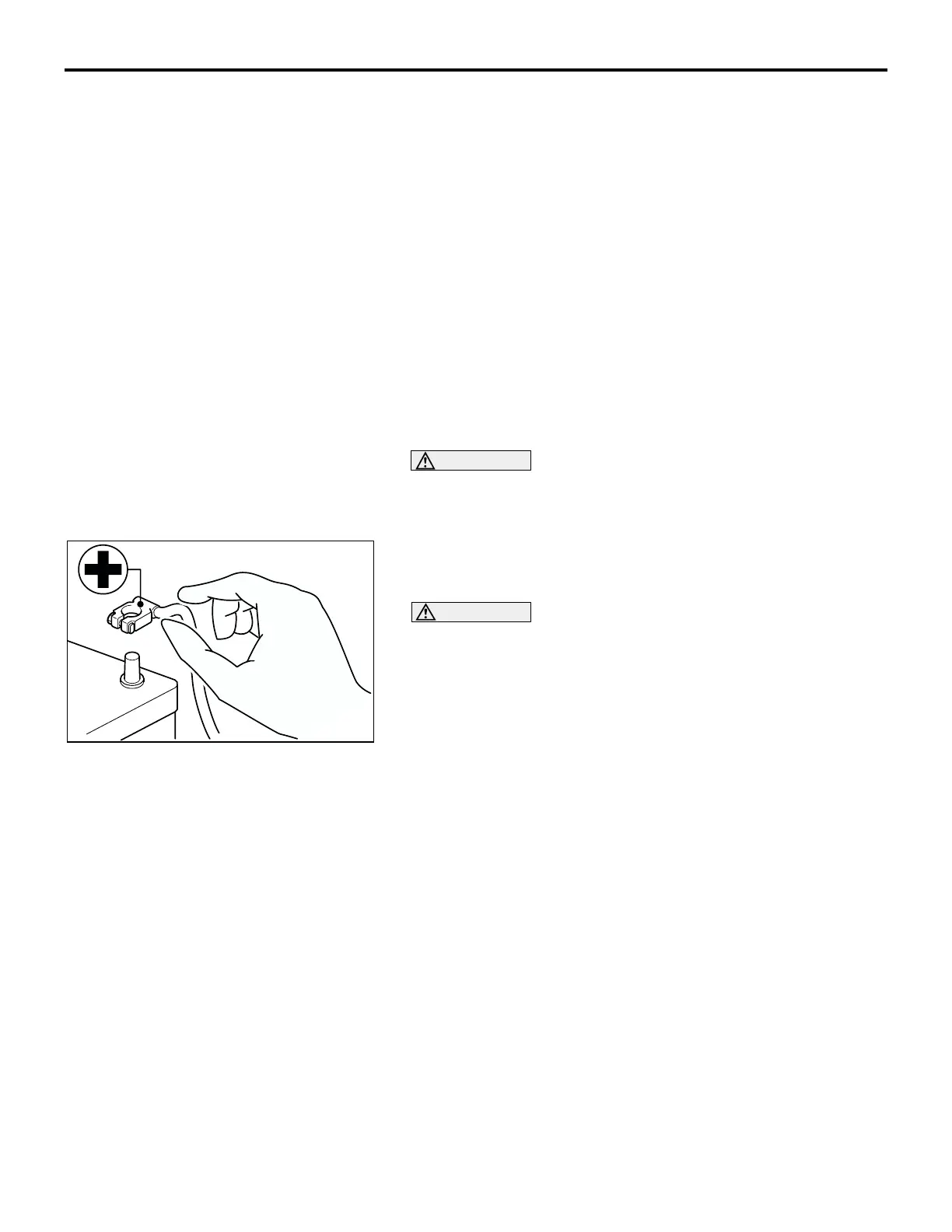

WARNING

Battery posts, terminals and related accessories con-

tain lead and lead compounds. WASH HANDS AFTER

HANDLING.

When the body is used as the ground during welding for body

repairs, be absolutely sure to first disconnect the battery's posi-

tive (+) cable.

CAUTION

• Be sure that both the ignition and lighting switches are

"LOCK" (OFF) position before either disconnecting or

reconnecting a battery cable. (If this is not done, equip-

ment containing semiconductors could be damaged.)

• Note that the memory of electronic equipment having a

memory function will be cleared when the battery cable

is disconnected.

NOTE: Vehicles today include a great many electronic parts

and components, and these are in general very susceptible to

adverse effects caused by overcurrent, reverse current, elec-

tromagnetic waves, high temperature, high humidity, impacts,

etc. In particular, such electronic components can be damaged

if there is a large current flow during welding from the body

side, etc.

This is because, for electronic components that incorporate a

back-up circuit (for memory retention) that functions (by a

trickle current) even when the ignition switch is at OFF, an elec-

tronic circuit is formed even when the switch is at OFF.

.

HANDLING COMBUSTIBLE MATERIALS

If welding work is to be done in the area of the fuel tank, the fuel

tank must be removed to prevent the generation of flammable

gases. Also be sure to cap the inlet port and the pipes of the

fuel tank after removal to prevent the escape of any fuel or

flammable gases.

Wipe up any fuel, oil, etc., spilled in the work area as soon as

possible.

AB200105

Loading...

Loading...