BALANCER CHAIN <4B12>

ENGINE OVERHAUL

11B-51

9. After tightening them to the specified torque of 20

N

⋅m again, use special tool Angle gauge

(MB991614) to tighten them up to 135

°.

10.Pull out the hexagonal bar wrench from the

balancer module sprocket.

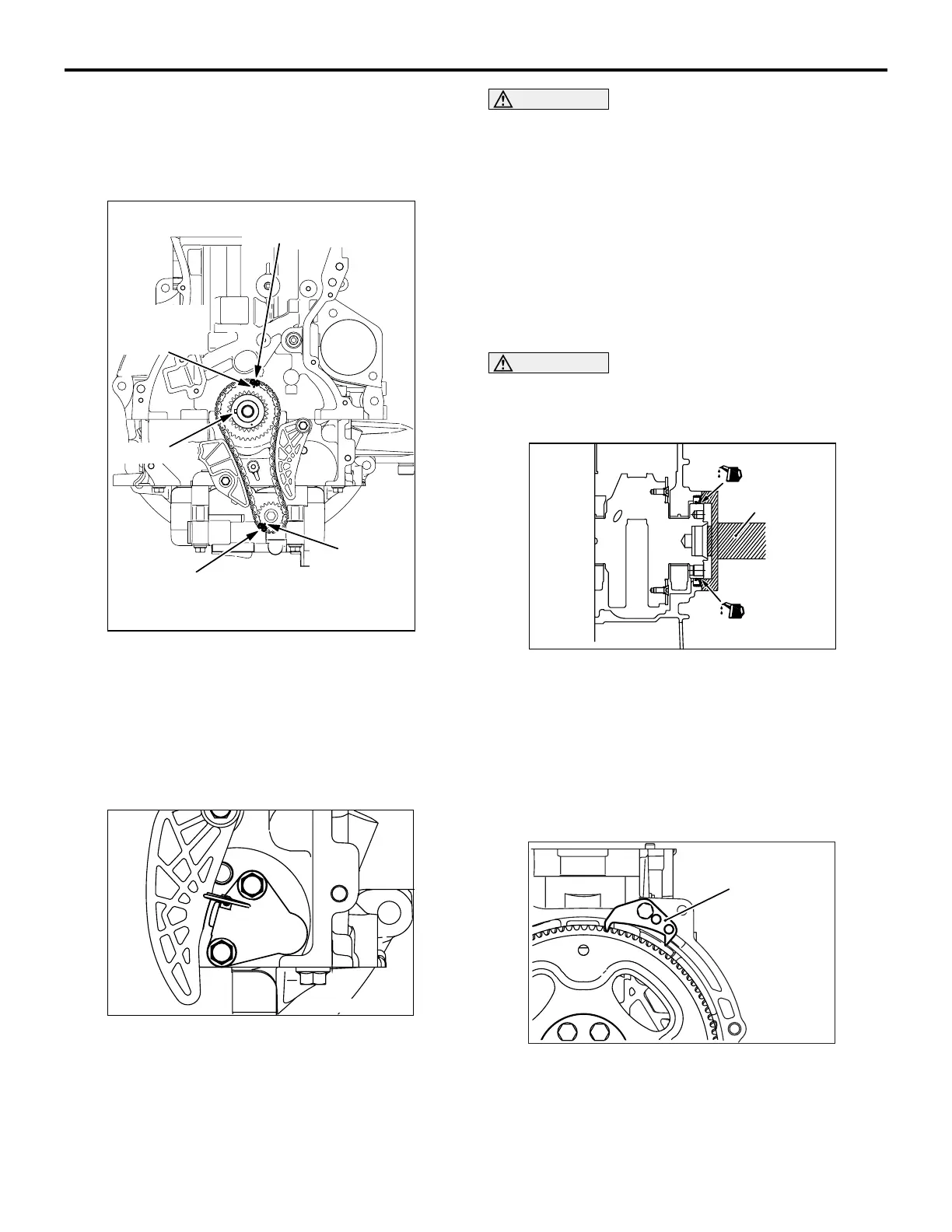

AK502923

Timing mark

link plate (orange)

Timing mark

link plate (blue)

Crank shaft

sprocket

timing mark

Key groove

Balancer shaf

sprocket

timing mark

AD

11.Make sure that the respective timing mark is

aligned with each other as illustrated.

12.Install the balancer chain tensioner lever and

balancer chain guide.

>>C<< BALANCER SHAFT CHAIN

TENSIONER INSTALLATION

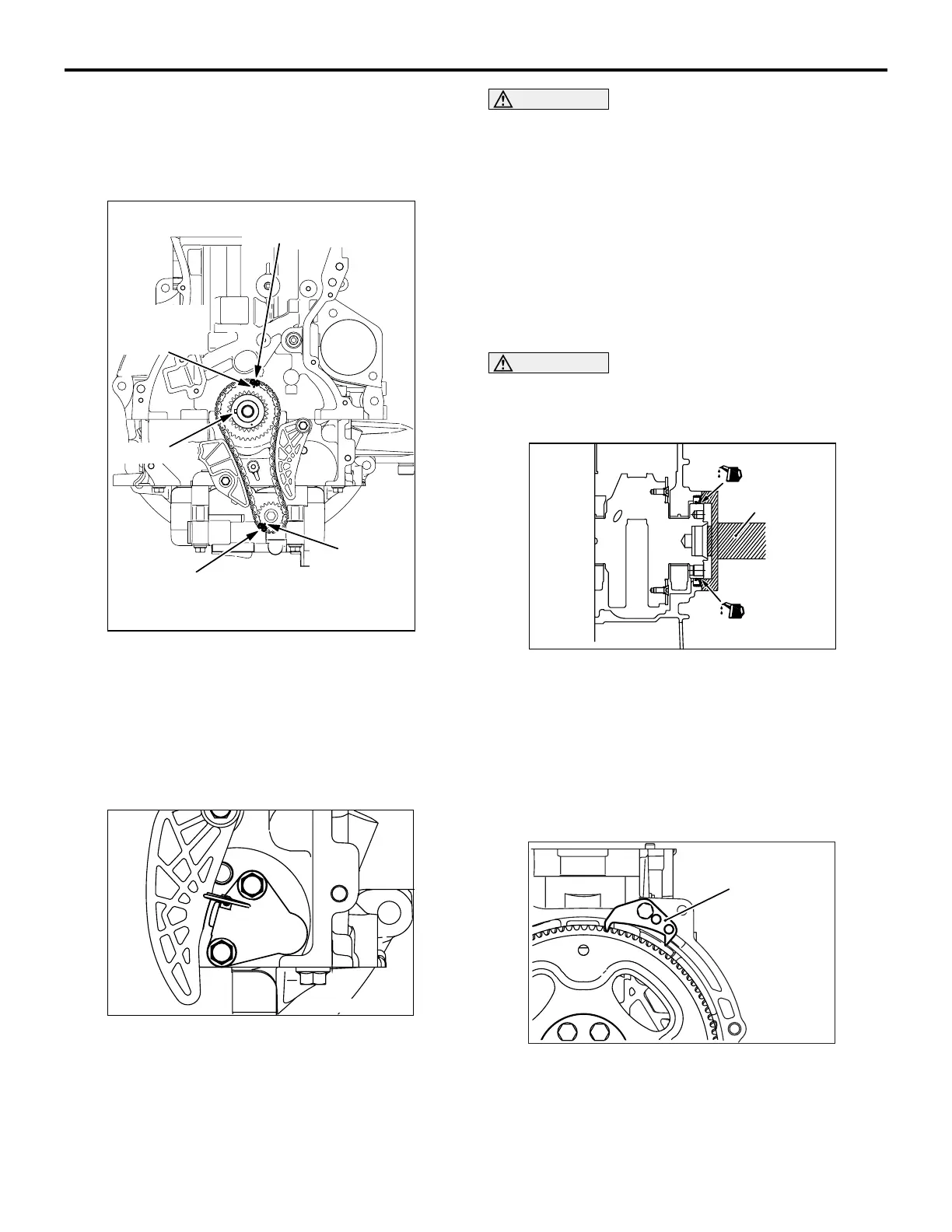

AK502940

1. Attach the chain tensioner to the ladder frame.

CAUTION

Install the chain tensioner precisely in place after

installing the tensioner lever and chain guide to

prevent the plunger of the chain tensioner from

jumping out.

2. Remove the hard wire (piano wire, etc.) of φ1.5 or

hexagonal bar wrench (1.5 mm) from the

tensioner. This enables the plunger of the chain

tensioner to push the balancer shaft tensioner

lever to keep the balancer shaft chain tight.

>>D<< REAR OIL SEAL INSTALLATION

CAUTION

Do not apply oil to the circumference of the oil

seal and oil seal pressing hole on the cylinder

block side to prevent teeth from pulling out.

AK502871

AC

MD998718

After applying a small amount of engine oil to the oil

seal lip, use special tool Rear oil seal installer

(MD998718) to press fit the oil seal.

>>E<< DRIVE PLATE BOLT

INSTALLATION

1. Clean off sealant and oil of thread of crankshaft

and drive plate bolts.

AK503335

AC

MB991883

2. Use special tool Flywheel stopper (MB991883) to

secure the drive plate.

Loading...

Loading...