AK603503

20

A

AC

Piston mark size

PISTON AND CONNECTING ROD

ENGINE OVERHAUL

11B-55

NOTE: The piston size mark is indicated on the

piston top face.

2. Insert the push rod into the piston pin and attach

guide A.

3. Align the front mark of the piston with that of the

connecting rod to assemble.

4. Apply engine oil to the circumference of the piston

pin.

5. Insert the guide A side of the piston pin

assembled in section 1 into the pin hole from the

front mark side of the piston.

AK502517

AC

L

Guide A

Guide B

6. Screw guide B into guide A and open clearance

between guide A and guide B by 3 mm (make the

base in line with flushed surface) to assemble.

7. Set the piston on special tool piston setting base

so that its front mark faces upward.

8. Use a press to press fit the piston pin. If the press

fit load is below the standard value, replace the

piston pin (piston assembly) or connecting rod, or

both.

Standard value: 7,500 − 17,500 N

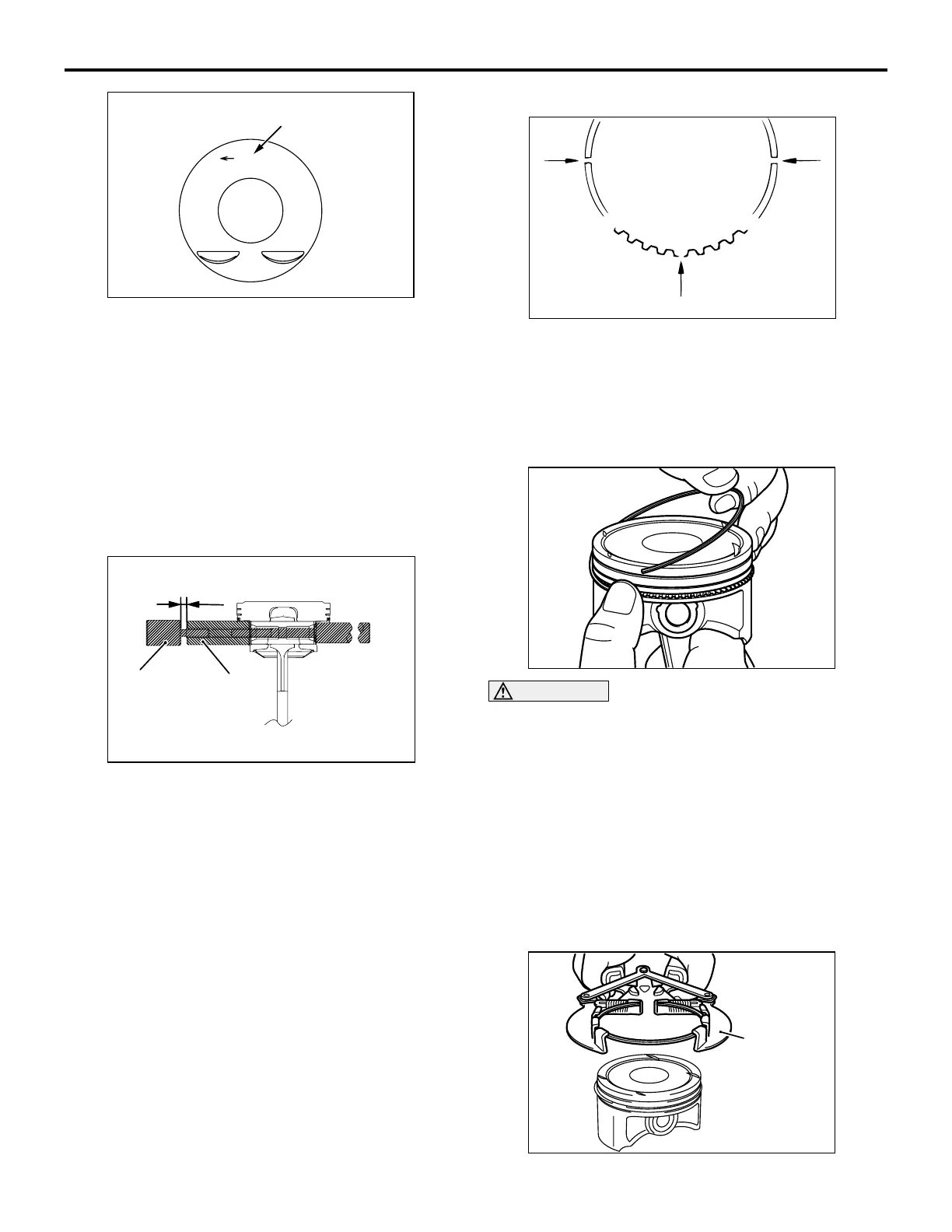

>>B<< OIL RING INSTALLATION

AK103812

AC

Upper

side

rail

closed

gap

Lower

side

rail

closed

gap

Spacer closed gap

1. Assemble the spacer of the oil ring into the piston

ring groove. Then, assemble the upper side rail,

and after this assemble the lower side rail.

NOTE: Install the side rail and end gap of the

spacer so that they are at the position as shown in

the illustration.

AK304891

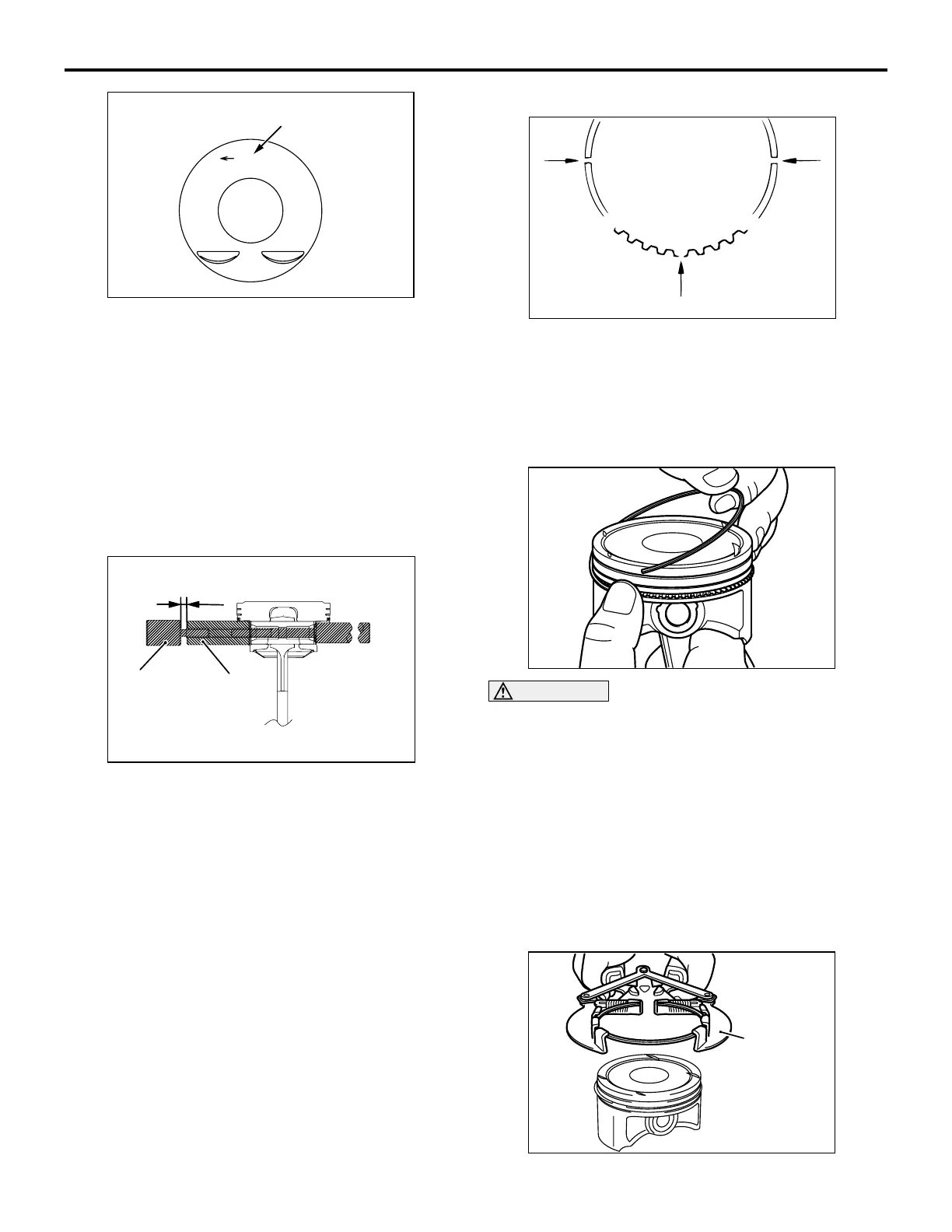

CAUTION

The side rail may be broken if its end gap is wid-

ened by a ring expander as in other piston rings.

2. When assembling the side rail, push it by fingers,

after fitting one end of the side rail into the piston

groove, for easy assembly.

3. After assembling the oil ring into the piston, make

sure that the side rail turns smoothly to either

direction.

>>C<< PISTON RING NO. 2 / PISTON

RING NO. 1 INSTALLATION

AK304892

AB

Piston ring

expander

Loading...

Loading...