These photos illustrate a method of repairing simple dents. They are intended to supplement Body

repair - minor

damage

in this Chapter and should not be used as the sole instructions for body repair on these vehicles.

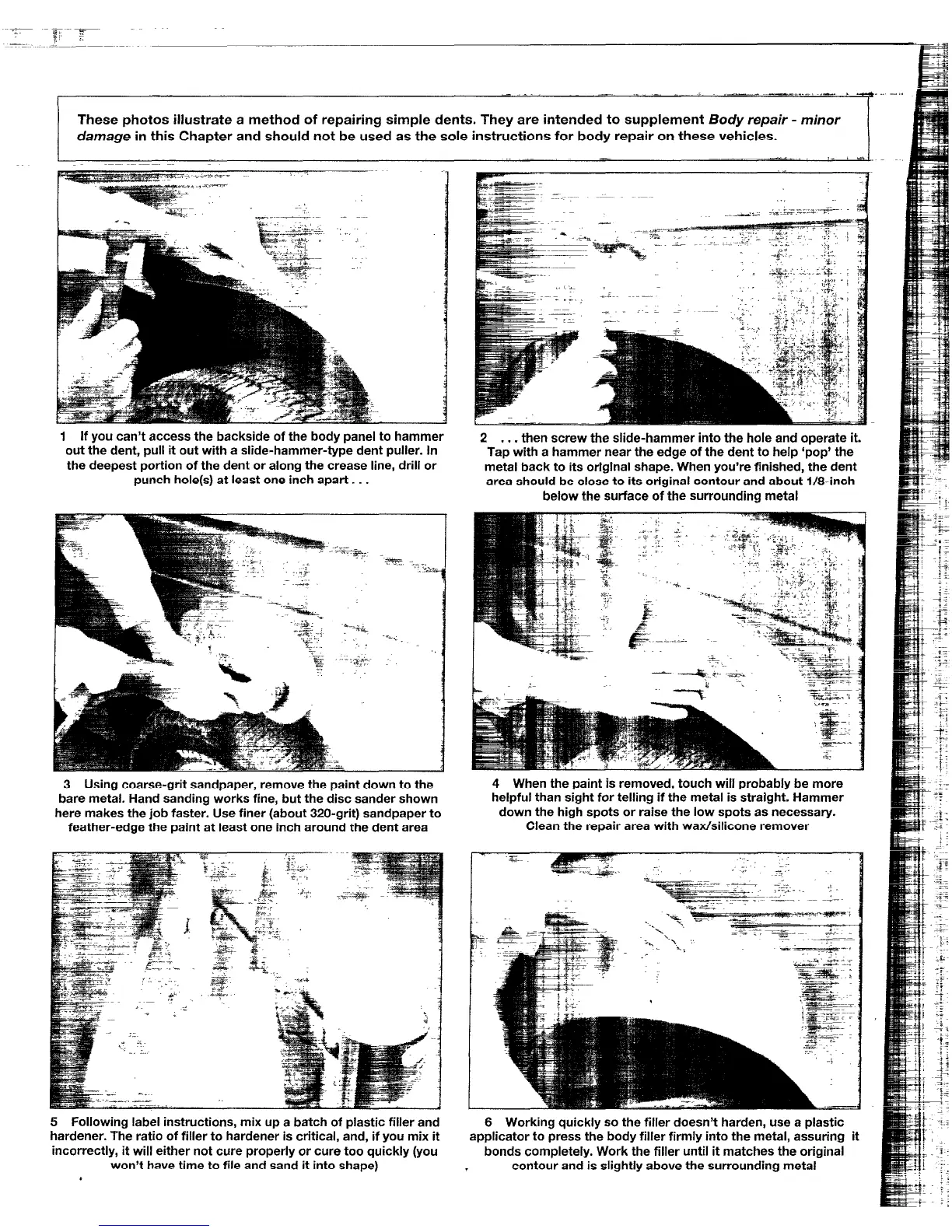

1 If you can’t access the backside of the body panel to hammer

out the dent,

pull it out with a slide-hammer-type dent puller. In

the deepest portion of the dent or along the crease line, drill or

punch hole(s) at least one inch apart. . .

3 Using coarse-grit sandpaper, remove the paint down to the

bare metal. Hand sanding works fine, but the disc sander shown

here makes the job faster. Use finer (about 320-grit) sandpaper to

feather-edge the paint at least one inch around the dent area

5 Following label instructions, mix up a batch of plastic filler and

hardener. The ratio of filler to hardener is critical, and, if you mix it

incorrectly, it will either not cure properly or cure too quickly (you

won’t have time to file and sand it into shape)

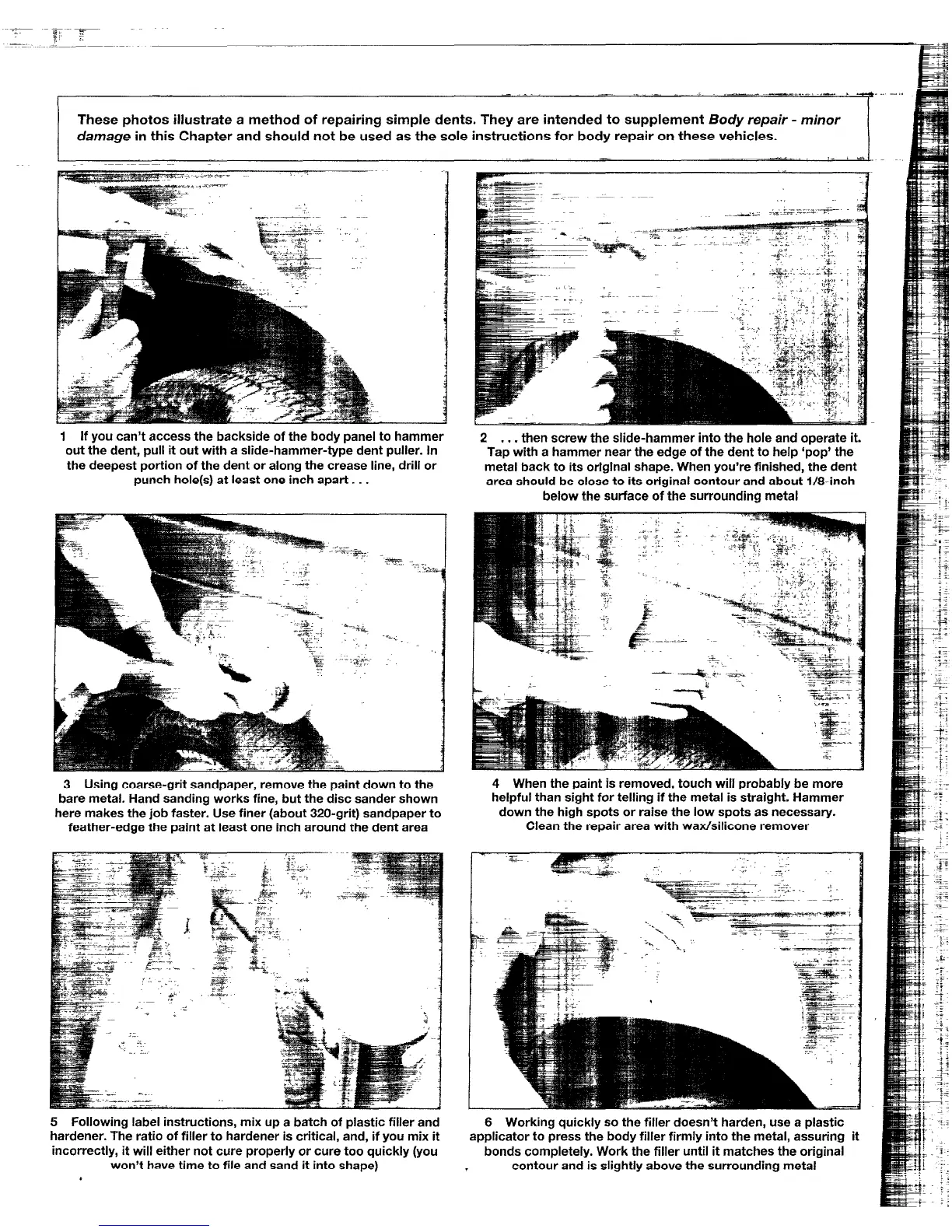

2 . . . then screw the slide-hammer into the hole and operate it.

Tap with a hammer near the edge of the dent to help ‘pop’ the

metal back to its orlglnal shape. When you’re finished, the dent

area should be close to its original contour and about l/%-inch

below the surface of the surrounding metal

4 When the paint is removed, touch will probably be more

helpful than sight for telling if the metal is stralght. Hammer

down the high spots or raise the low spots as necessary.

Clean the repair area with wax/silicone remover

6 Working quickly so the filler doesn’t harden, use a plastic

applicator to press the

body

filler firmly into the metal, assuring it

bonds completely. Work the filler until it matches the original

9

contour and is slightly

above

the surrounding metal

Loading...

Loading...