1 - 5 1 - 5

MELSEC-Q

1 GENERAL DESCRIPTION

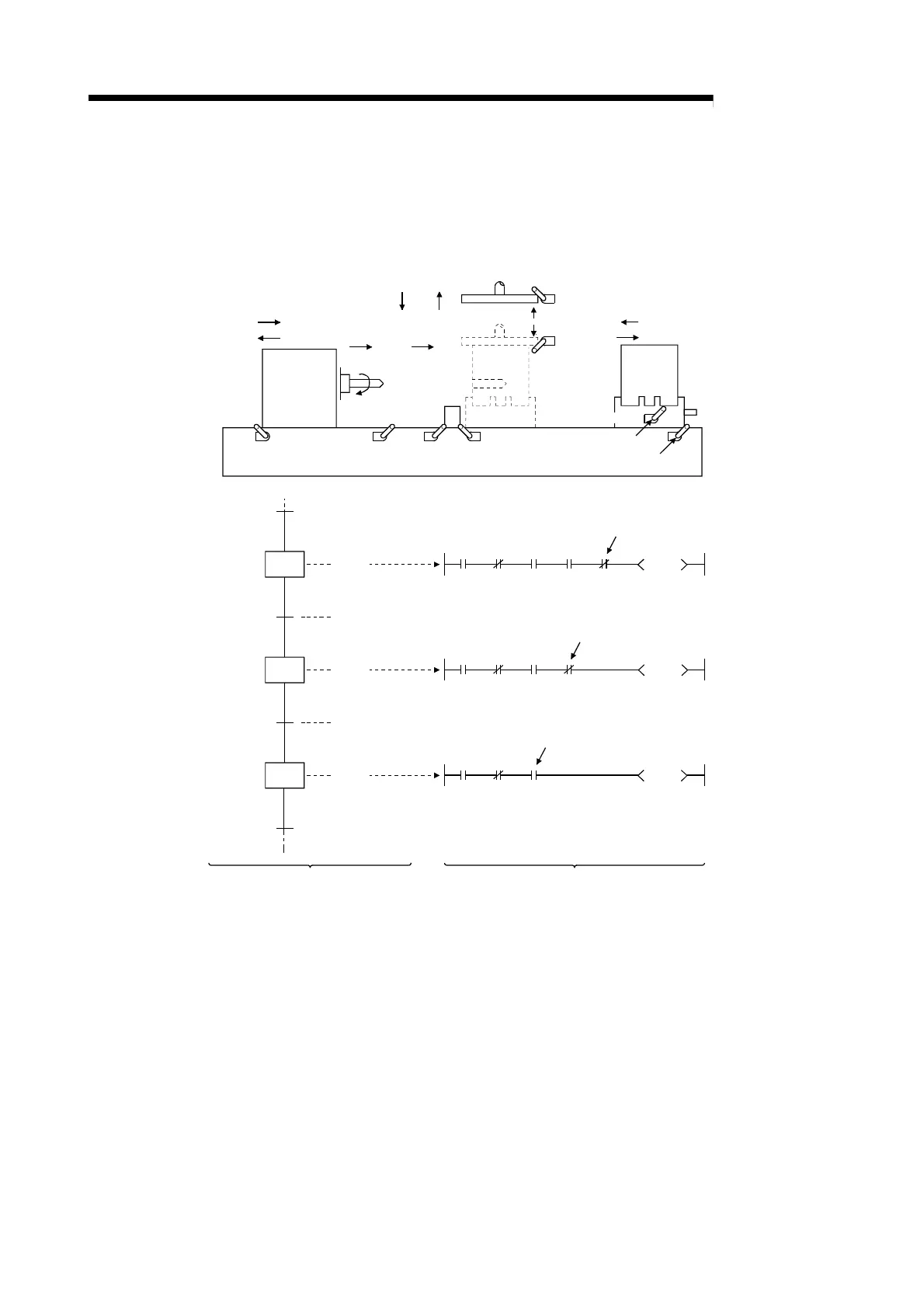

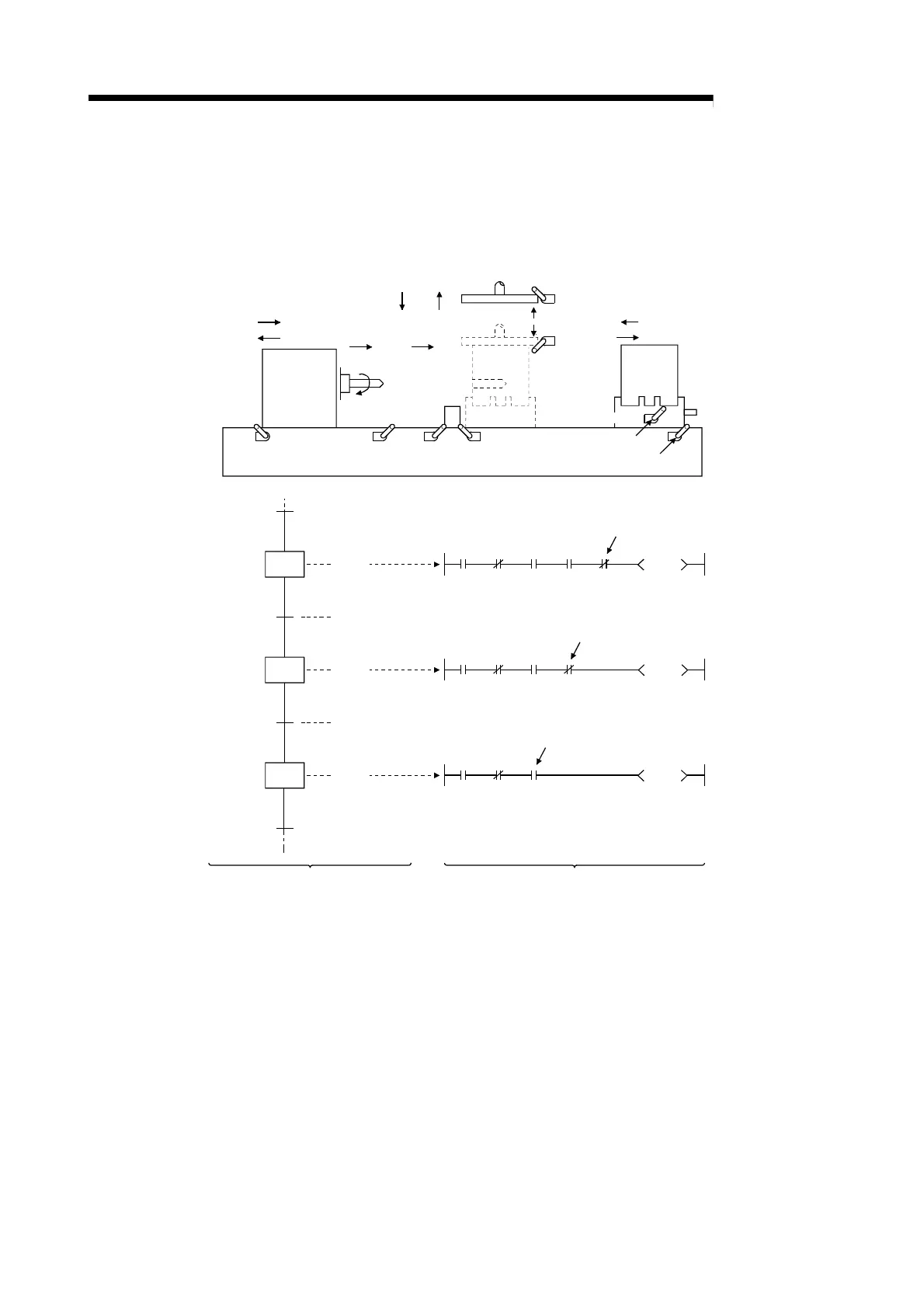

(2) Program development efficiency is enhanced by dividing control into parts

The machine control process can be divided into parts by describing the operation sequence

and machine control separately. The MELSAP-L is used to describe the operation sequence

for the machine, and a sequence program (circuit/list) is used to describe the machine control

including individual interlock.

SOL1

SOL2

Clamp

LS-U

Clamp UP endpoint

Clamp DOWN endpoint

MTO-F

MTO-B

MT1-F

MT1-B

Headstock

rotation

MT2-R

LS10

LS-D

Carriage

(Headstock RETRACT

endpoint)

LS0

(Machining

START)

LS1

(Machining

END)

LS2

(Carriage ADVANCE

endpoint)

LS-F

(Carriage RETRACT endpoint)

LS-R

oM0

Carring ADVANCE

Carring ADVANCE endpoint

aX13

oM1

Clamp DOWN

step 6

Clamp DOWN endpoint

aX17

oM2

Headstock ADVANCE

step 7

step 5

SFC program

M2 X12

Y20

M0

Y24

X13 X10

X16

M1

Y22

X17

X10

Interlock such as

emergency stop

Interlock such as

emergency stop

Interlock such as

emergency stop

Sequence program

Loading...

Loading...