9 - 72

MELSEC-Q

9 MAJOR POSITIONING CONTROL

(5) A "No command speed error (error code: 503)" occurs if a current speed (-1) is

set in "

Da.8

Command speed".

(6) The software stroke limit check is not carried out when the control unit is set to

"degree".

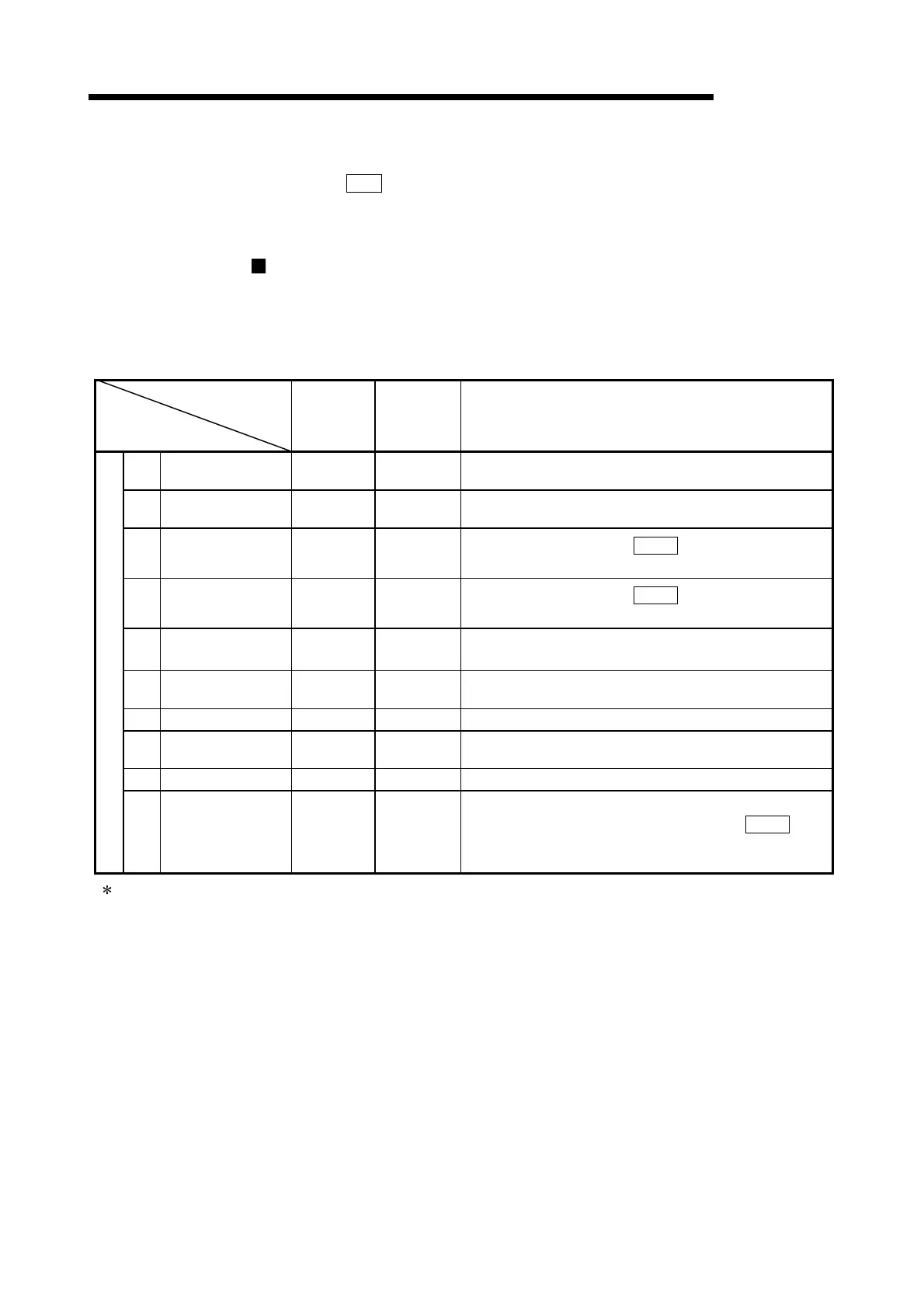

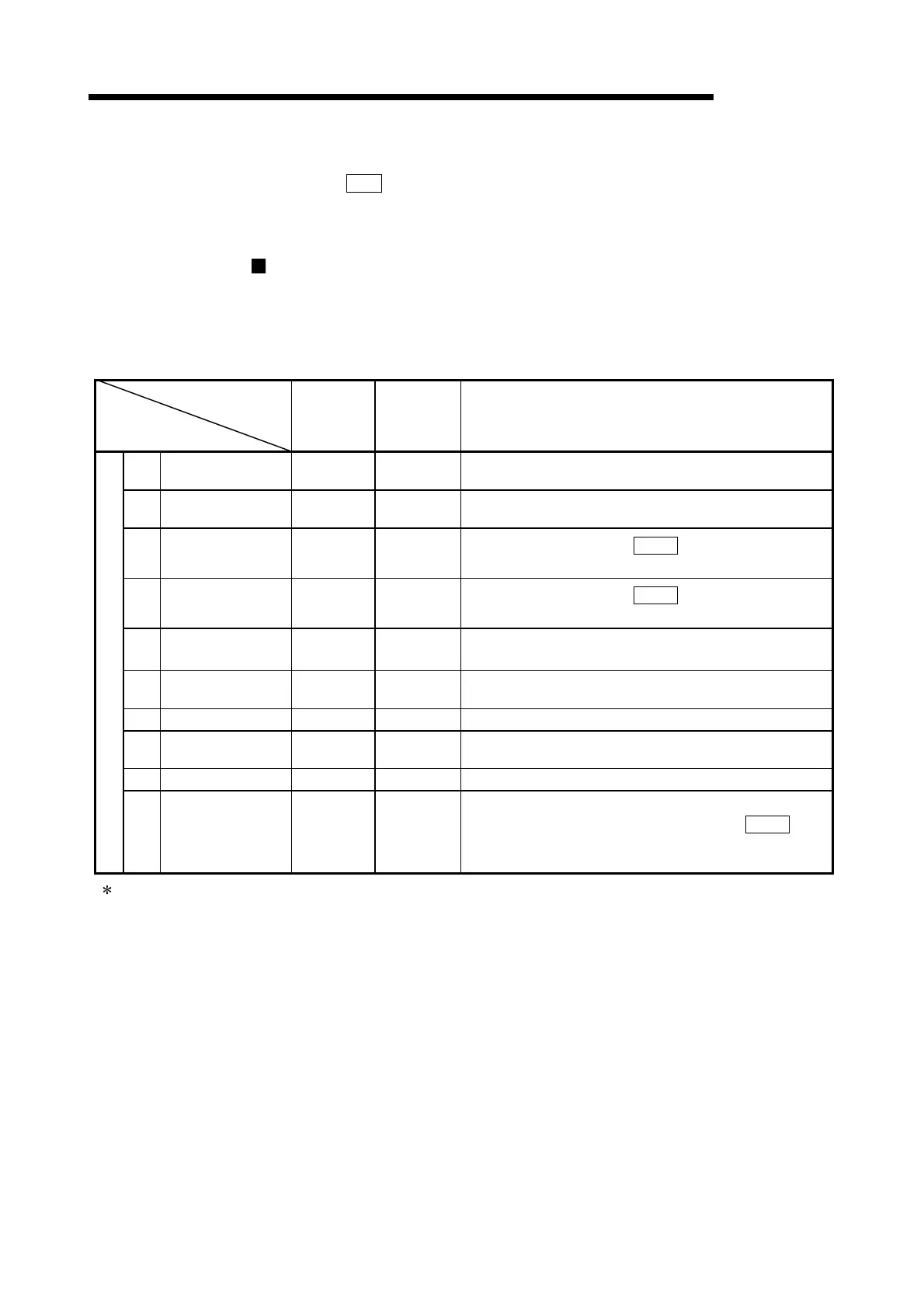

Positioning data setting examples

[Setting examples when the reference axis and interpolation axis are designated

as axes 1 and 2, respectively.]

The following table shows the setting examples when "2-axis speed control

(forward run: speed 2)" is set in the positioning data No. 1 of axis 1 (reference

axis).

Axis

Setting item

Axis 1

(reference

axis) setting

example

Axis 2

(interpolation

axis) setting

example

Setting details

Da.1 Operation pattern Termination –

Setting other than "termination" is not possible in speed

control.

Da.2 Control system

Forward run

speed 2

– Set 2-axis speed control.

Da.3

Acceleration time

No.

1 –

Designate the value set in "

Pr.25

Acceleration time 1" as

the acceleration time at start.

Da.4

Deceleration time

No.

0 –

Designate the value set in "

Pr.10

Deceleration time 0" as

the deceleration time at deceleration.

Da.5

Axis to be

interpolated

2

–

Set the axis to be interpolated (partner axis).

If the self-axis is set, an error will occur.

Da.6

Positioning address/

movement amount

– – Setting not required (setting value will be ignored).

Da.7 Arc address – – Setting not required (setting value will be ignored).

Da.8 Command speed

6000.00

mm/min

3000.00

mm/min

Set the speed to be commanded.

Da.9 Dwell time – – Setting not required (setting value will be ignored).

Axis 1 Positioning data No. 1

Da.10

M code 10 –

Set this when other sub operation commands are issued in

combination with the No. 1 positioning data. ("

Pr.18

M

code ON signal output timing" setting only possible in the

WITH mode.)

Refer to section "5.3 List of positioning data" for information on the setting details.

Loading...

Loading...