15 - 7

MELSEC-Q

15 TROUBLESHOOTING

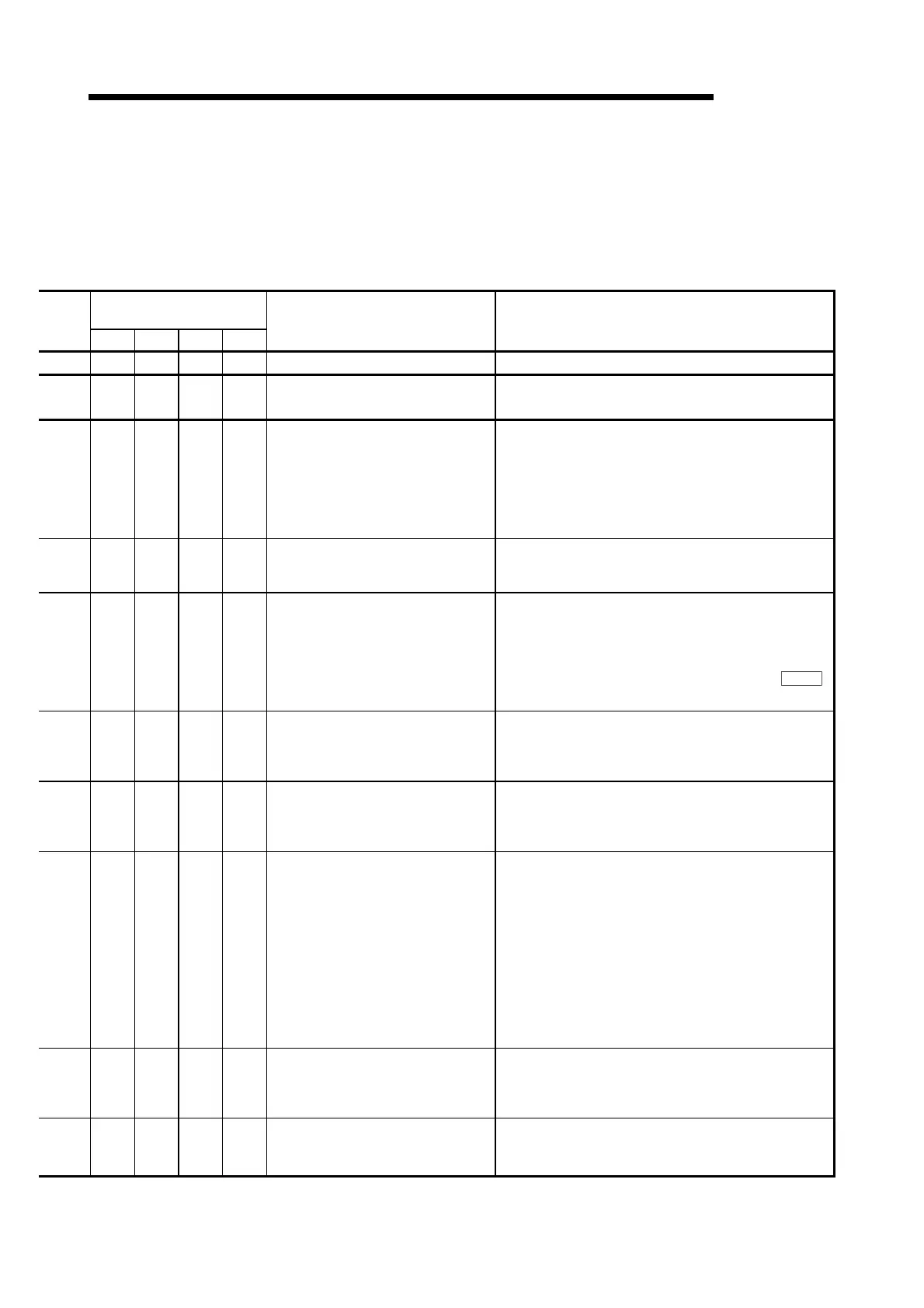

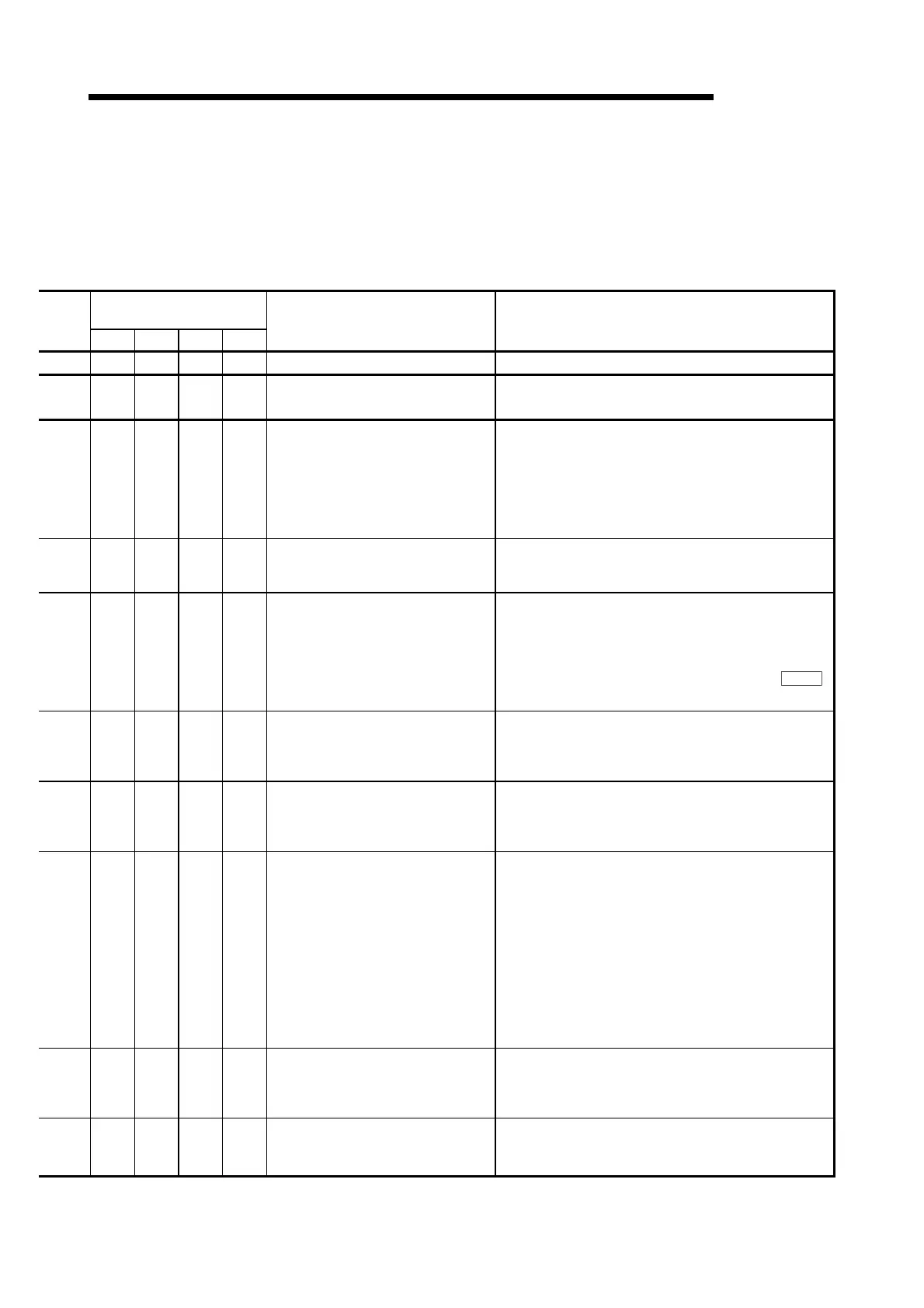

Related buffer memory

address

Axis 1 Axis 2 Axis 3 Axis 4

Set range

(Setting with sequence program)

Remedy

— — — — — —

— — — — —

• Check that there is no influence from noise.

• Check hardware for possibility of fault.

— — — — —

• Review the sequence program which turns ON/OFF

PLC READY signal (Y0).

• Cancel the error with an axis error reset.

(Refer to section 15.1[3])

— — — — —

Check the servo amplifier power, wiring with the servo

amplifier, and connection of connectors, and cancel the

error with an axis error reset. (Refer to section 15.1[3])

— — — — —

• Check that there is no error on the personal computer

side I/F to which a cable is connected.

• Change the transmission speed (serial communica-

tion baud rate selection) between the personal com-

puter and the QD75. (Refer to section 5.2.9 "

Pr.133

")

— — — — —

Moving the system to a position where an upper limit

signal is not input using the manual control operation

(refer to chapter 11) after the axis error reset (Refer to

section 15.1[3]).

— — — — —

Moving the system to a position where a lower limit

signal is not input using the manual control operation

(refer to chapter 11) after the axis error reset (Refer to

section 15.1[3]).

— — — — —

Check whether the stop commands (output

signals/external inputs to QD75) are turned ON or

OFF. Turn OFF the ON commands.

• Output signals to QD75

Axis 1: Y4, Axis 2: Y5, Axis 3: Y6, Axis 4: Y7

• External input

Connectors for external device connection:

Stop signals (STOP)

After confirming the stop command status, cancel the

error with an axis error reset. Then turn ON a start

signal. (Refer to section 15.1[3])

— — — — —

The PLC READY signal (Y0) is turned from OFF to ON

when all BUSY signal is turned OFF.

— — — — —

Do not request the start when the axis operation state

is other than "standby", "stop", and "step standby".

Loading...

Loading...