14 APPENDIX

Mitsubishi Diesel Engine S16R & S16R2 OPERATION & MAINTENANCE MANUAL

210

Pub. No. K29001-00320 Revision: 1

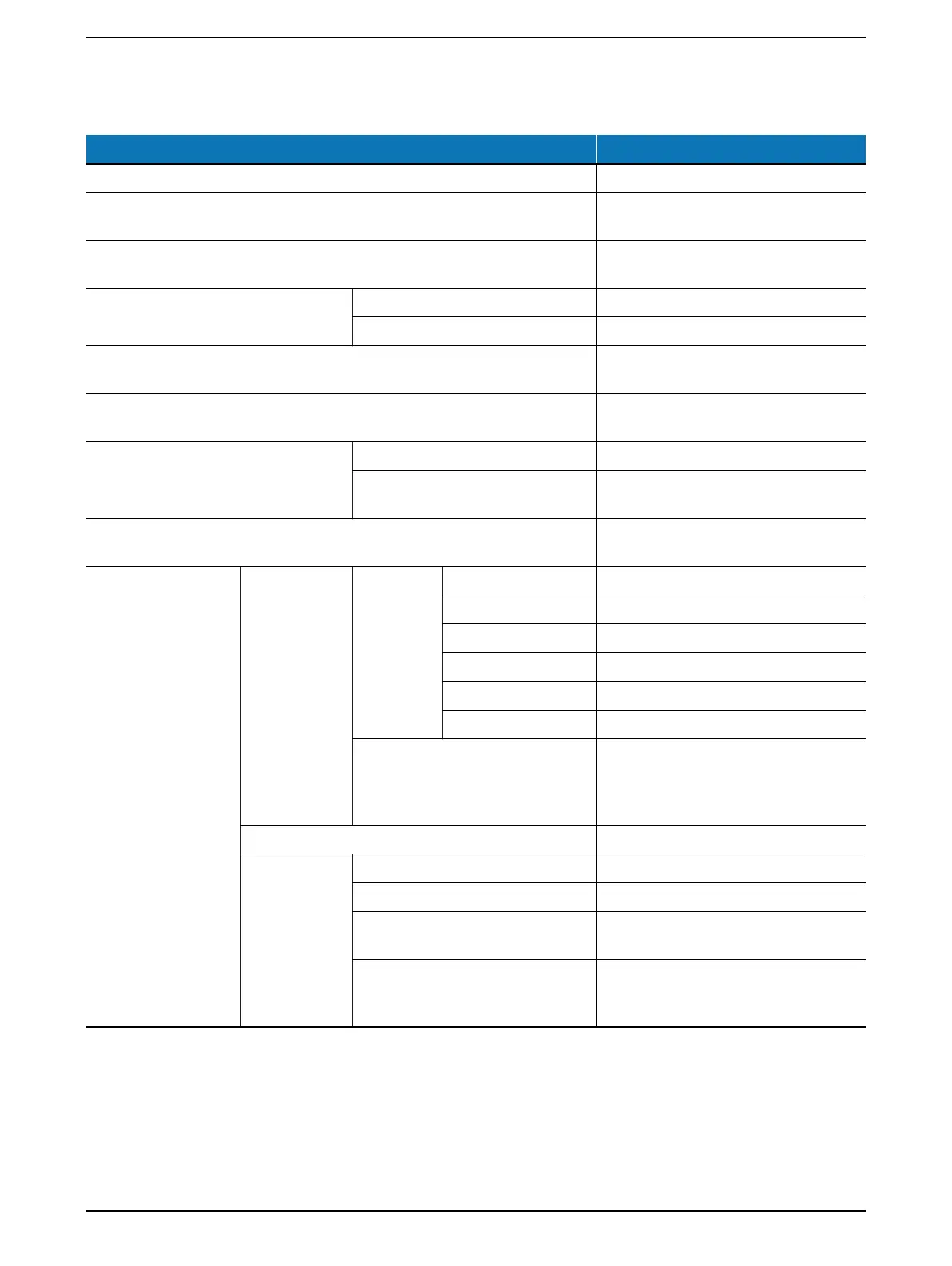

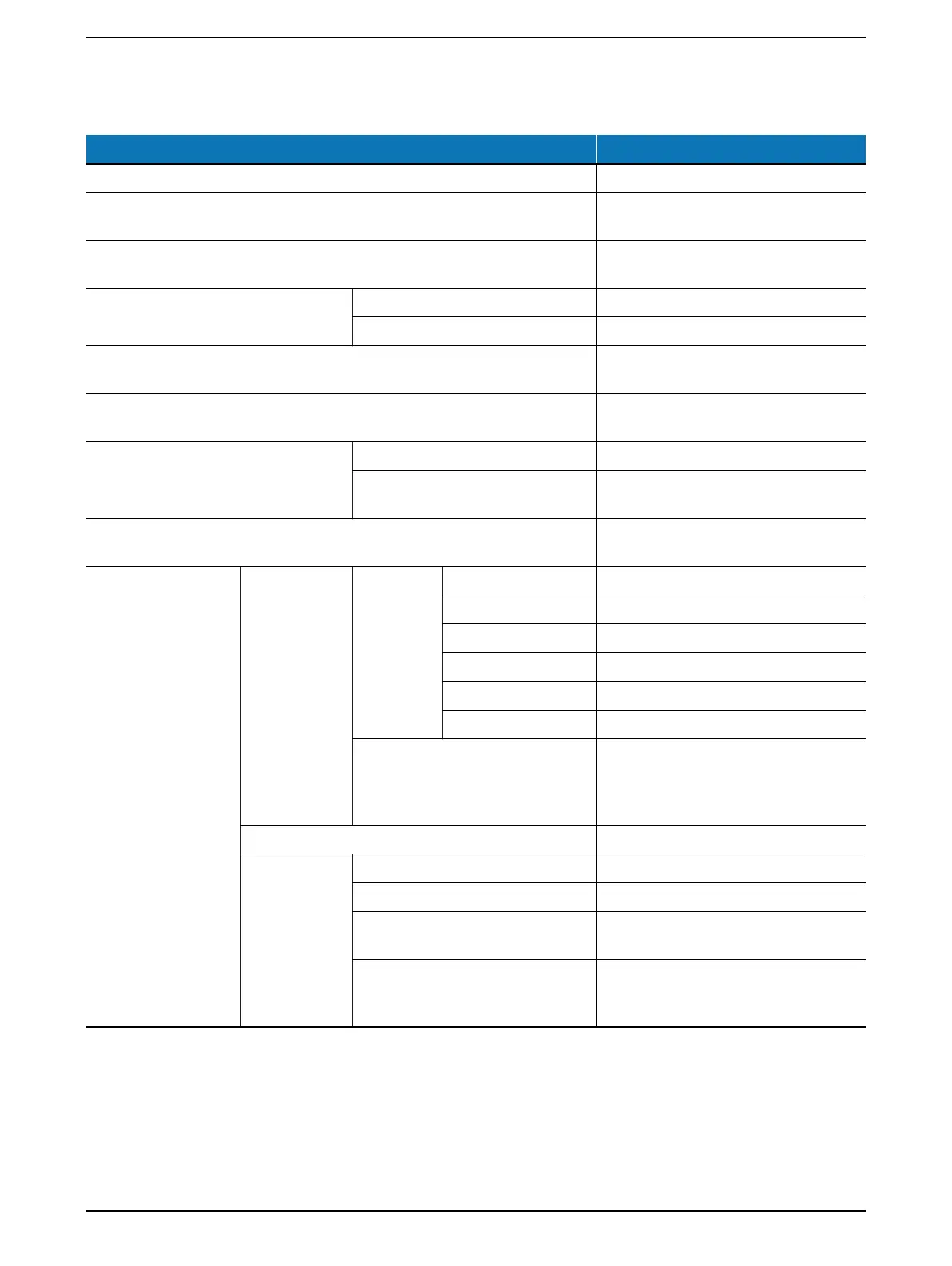

Table 14-4 LLC Specifications (1/3)

Test items Standard value

External appearance No precipitation

Specific gravity

Minimum 1.112 (20/20°C) [68/68 °F]

(undiluted solution)

Water content

Maximum 5.0 weight% (undiluted

solution)

Freezing temperature

30 volumetric% water solution -14.5°C [5.9°F] or lower

50 volumetric% water solution -34.0°C [-29.2°F] or lower

Equilibrium reflex boiling point

155°C [311°F] or higher (undiluted

solution)

pH

7.0 to 11.0 (30 volumetric% water

solution)

Foamability (ASTM D3306-01)

30 volumetric% water solution 4.0 ml or less

33 1/3 volumetric% water solu-

tion

150 ml or less, defoaming time 5

sec. or less

Hard water compatibility

1.0 or less (50 volumetric% water

solution)

Corrosive to metal

(88 ± 2°C

[190.4 ± 3.6°F],

336 ± 2 Hr,

30 volumetric% wa-

ter solution {eth-

ylene glycol}, 50

volumetric% water

solution {propylene

glycol})

Metallic test

piece

Mass

change

Aluminum ±0.30 mg/cm

2

Cast iron ±0.15 mg/cm

2

Steel ±0.15 mg/cm

2

Brass ±0.15 mg/cm

2

Solder ±0.30 mg/cm

2

Copper ±0.15 mg/cm

2

Visual inspection of test piece af-

ter testing

Any corrosion must not be observed

except for the contacting position of

the test piece and spacer. Discolor-

ation is allowed.

Bubble formation during test Bubbles must not overflow.

Property of

liquid after

test

pH 6.5 to 11.0

pH change ± 1.0

Precipitation

0.5 volumetric% water solution or

less

Visual inspection of liquid

No significant discoloration.No sig-

nificant changes such as separation

and gel generation.

Loading...

Loading...