ELECTRICAL SYSTEM

12-13

2.5 Inspecting and adjusting after reassembling

2.5.1 Inspecting pinion clearance

&$87,21

Do not apply current continuously for longer than 10

seconds.

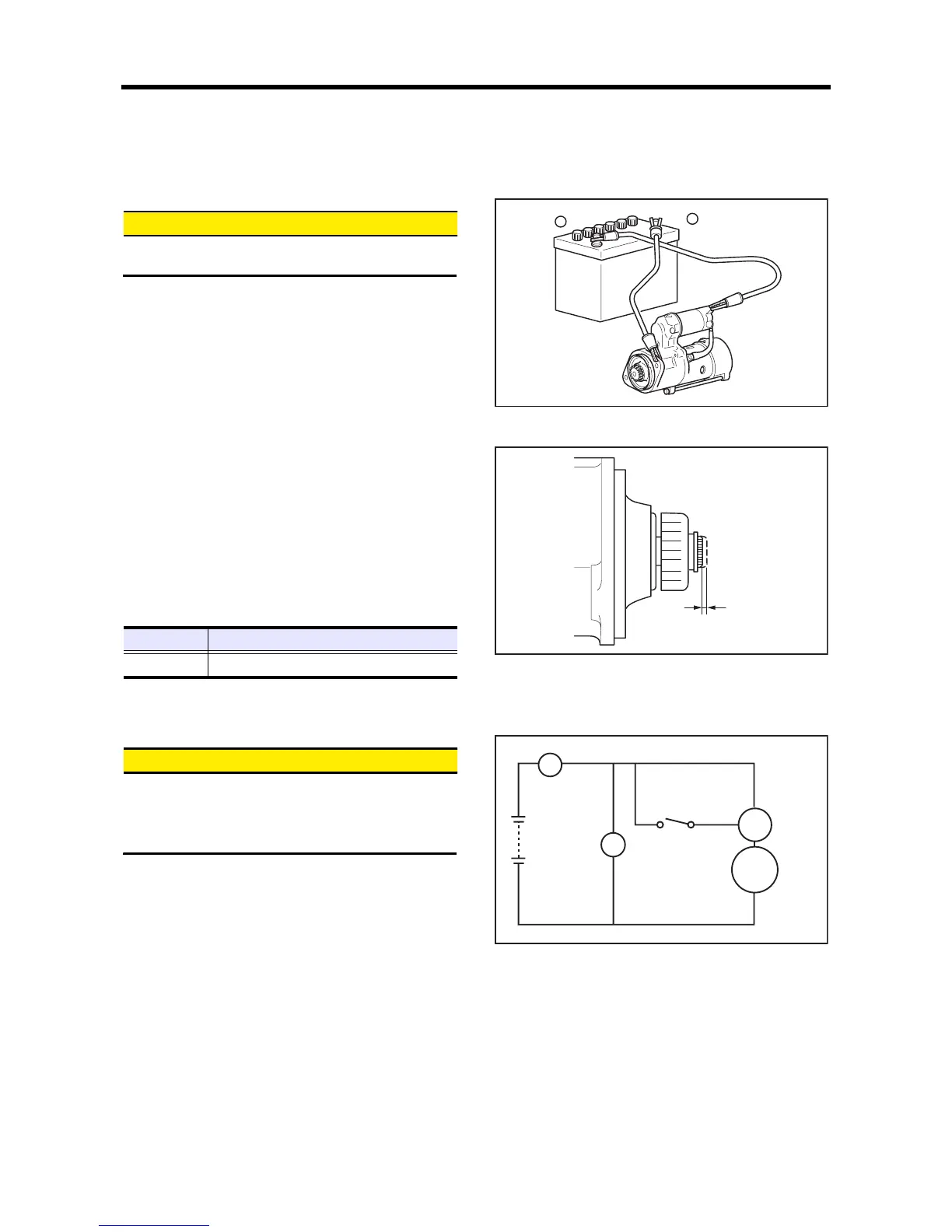

(1) Since connecting the wires of the reassembled starter as

shown in the diagram causes the pinion to extends and

rotate slowly, disconnect the connector from terminal

M to stop the rotation.

(2) Lightly push the tip of the extended pinion shaft with a

finger, and measure the distance of the shaft movement

to obtain the pinion gap measurement.

Adjust the pinion gap by varying the number of

packings installed at the magnetic switch section so that

it conforms to the standard value. When the number of

packings is increased, the pinion gap decreases.

If proper adjustment cannot be achieved by varying the

number of packings, replace the lever.

Ajusting pinion gap(1)

Ajusting pinion gap(2)

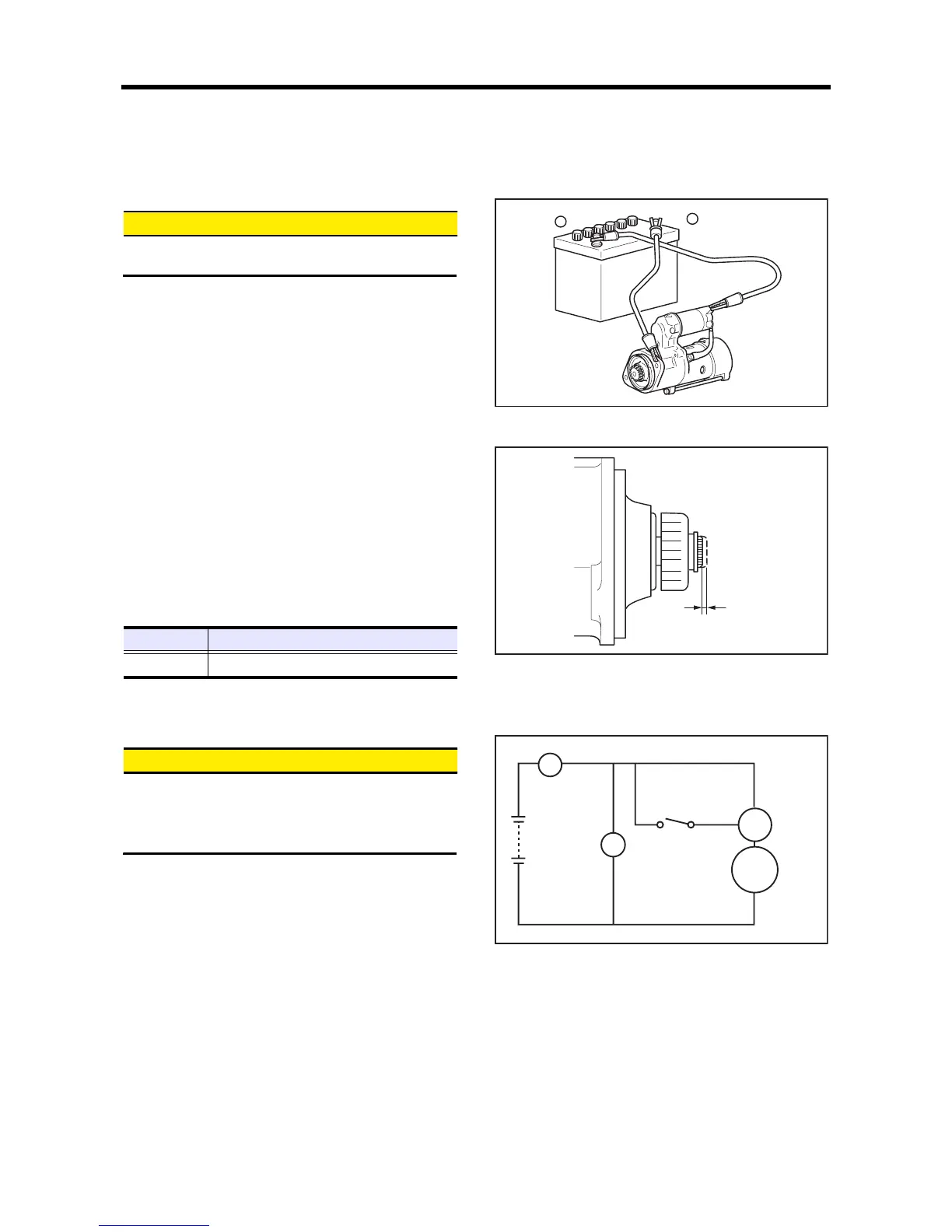

2.5.2 No load test

&$87,21

Use as thick a wire as possible and firmly tighten each

terminal.

When detecting the rotation at the tip of the pinion, be

careful, as the pinion pops out during operation.

(1) Connect the starter to the circuit as shown in the

illustration.

(2) In normal condition, the pinion pops out when the

switch is turned ON, and the starter rotates at or more

the specified rotation speed.

If the terminal voltage, current or rotation speed does

not meet the standard, disassemble, inspect and repair

the starter.

Test at no load

Item Standard

Pinion gap 0.5 to 2.0 mm [0.020 to 0.079 in.]

Terminal S

Terminal M

Battery

Pinion gap

A

V

B

M

S

Ammeter

Battery

Volt meter

Switch

Switch

Starter

Loading...

Loading...