ADJUSTMENT AND OPERATION

13-3

1.2 Inspecting and adjusting fuel injection timing

1.2.1 Inspecting fuel injection timing

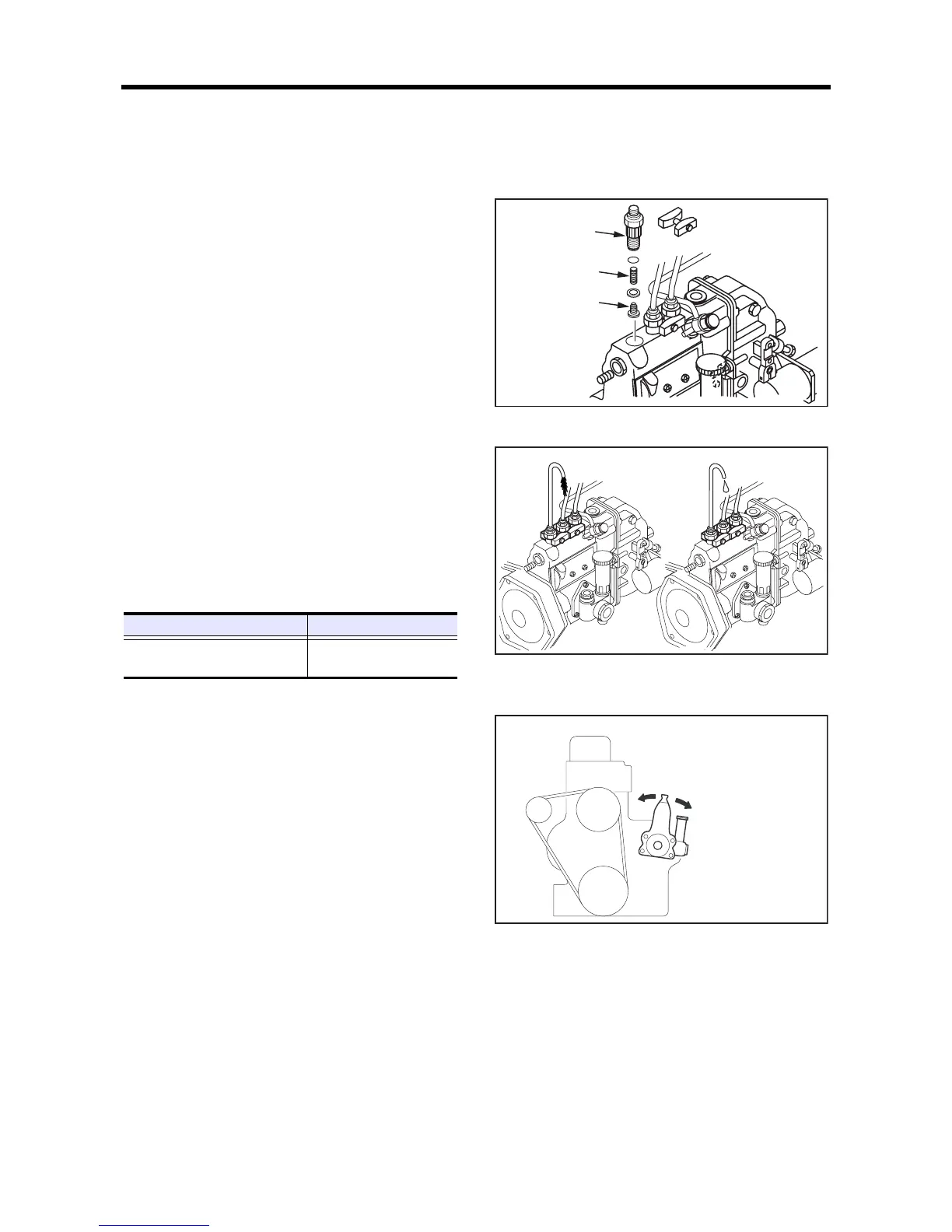

(1) In advance, bring the piston of No.1 cylinder to

compession top dead center. Remove the delivery valve

holder, delivery valve, spring and stopper from the

No.1 cylinder of the fuel injection pump, and reinstall

the delivery valve holder only.

(2) Install a spare injection pipe to the No.1 plunger of the

fuel injection pump. Face the other end of the injection

pipe to downward so that the fuel flow-out condition

can be seen clearly.

(3) Rotate the crankshaft to 60 degree before compression

top dead center of No.1 cylinder.

(4) Feed the injection pump using the priming pump. With

flowing the fuel out from the injection pipe, rotate the

crankshaft gradually in the normal direction.

(5) When the fuel flow is getting fewer, rotate the

crankshaft more slowly. When the fuel flow stop

completely, stop rotating the crankshaft.

(6) Make sure the pointer indicates the fuel injection timing

of the graduation mark on the crankshaft pulley.

Inspecting fuel injection timing (1)

Inspecting fuel injection timing (2)

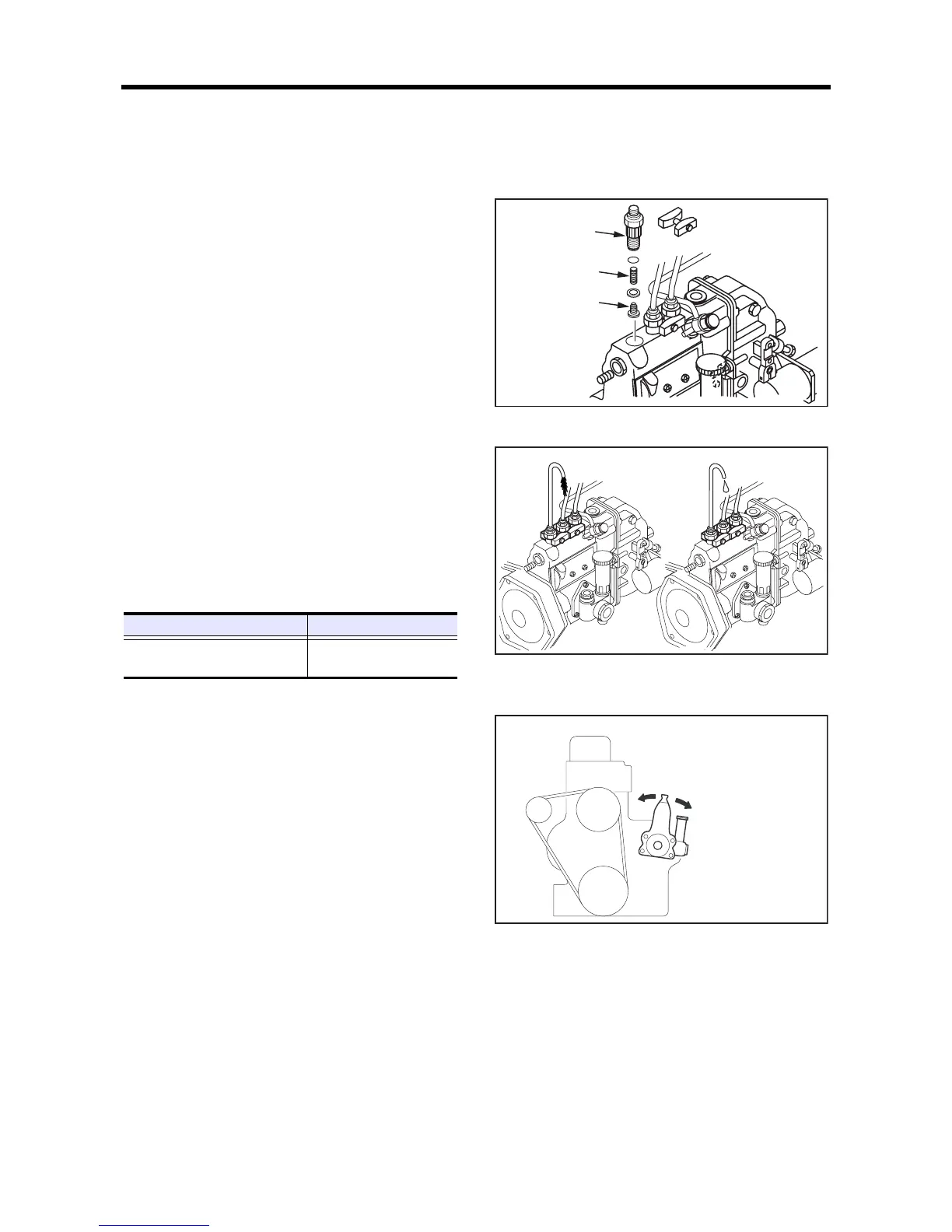

1.2.2 Adjusting fuel injection timing

To advance the fuel injection timing, turn the fuel injection

pump toward the crankcase.

To retard the fuel injection timing, turn the fuel injection

pump away from the crankcase.

Adjusting fuel injection timing

Item Standard

Fuel injection timing

Varies depending on the

specifications

Delivery valve

holder

Delivery valve

Spring

Advance timing when

later than normal

Retard timing when

earlier than normal

Loading...

Loading...