Control Operating Sequence

Unit heaters are supplied with standing pilot control systems

as standard or intermittent pilot systems with continuous retry

as an option. On standing pilot and mechanical modulation

systems the main burner is turned off 100% when the

thermostat is satisfied, but the pilot remains lit. For intermittent

pilot systems, except mechanical modulation both the main

burner and pilot burner are turned off 100% when the

thermostat is satisfied. Standing pilot systems, for both natural

and propane gas, have a manually lit pilot which stays lit until

the gas valve is manually turned to the off position. On a call

for heat, the gas valve opens, sending gas to the burner

allowing the unit to fire. Intermittent pilot systems, for both

natural and propane gas, the ignition controller is 100% shut-off

with continuous retry. On a call for heat, the system will attempt

to light the pilot for 70 seconds. If the pilot is not sensed for any

reason, the ignition control will wait for approximately six

minutes with the combination gas control closed and no spark.

After six minutes, the cycle will begin again. After three cycles,

some ignition controllers lockout for approximately one hour

before the cycle begins again. This will continue indefinitely until

the pilot flame is sensed or power is interrupted to the system.

Refer to table 14.1 for control code descriptions.

NOTE: Gas Control Options could change the listed

sequence of operation based on their function.

The descriptions given are for the basic unit heater.

Single-Stage Gas Controls (standing pilot)

Utilizes a single-stage combination gas control with a standing

pilot operator and a single-stage low voltage thermostat.

1. Pilot is lit continuously.

2. The thermostat calls for heat.

3. The main gas valve is opened and the main burner is lit to

100% full fire.

4. The air mover starts after 30 to 90 seconds.

5. The unit continues to operate until the thermostat is

satisfied, at which time the main valve closes 100%.

6. The air mover stops after 30 to 90 seconds.

Single-Stage Gas Controls (intermittent pilot)

Utilizes a single-stage combination gas, an ignition control, and

a single-stage low voltage thermostat.

1. The thermostat calls for heat.

2. The pilot valve opens and the spark ignitor sparks in an

attempt to light the pilot.

3. Once the pilot is lit, the flame sensor proves the pilot and

stops the spark ignitor from sparking.

4. The main gas valve is opened and the main burner is lit to

100% full fire.

5. The air mover starts after 30 to 90 seconds.

6. The unit continues to operate until the thermostat is satisfied,

at which time both the main and pilot valves close

100%.

13

Table 13.1

Manifold Pressure & Gas Consumption

➀

Natural Propane

BTU/Cu. Ft. 1050 2500 No. of

Model Specific Gravity 0.60 1.53 Orifices

Manifold Pressure In. W.C. 3.5 10.0

CFH 28.6 12.0

PD 30 Gal/Hr. Propane – .33 1

Orifice Drill Size 38 52

CFH 47.6 20.0

Gal/Hr. Propane – .55 1

Orifice Drill Size 30 45

CFH 71.4 30.0

Gal/Hr. Propane – .82 1

Orifice Drill Size 21 39

CFH 95.2 40.0

Gal/Hr. Propane – 1.15 2

Orifice Drill Size 30 45

CFH 119.0 50.0

Gal/Hr. Propane – 1.43 2

CFH 138.1 58.0

Gal/Hr. Propane – 1.64 2

Orifice Drill Size 21 39

CFH 166.7 70.0

Gal/Hr. Propane – 1.86 3

Orifice Drill Size 28 43

CFH 190.5 80.0

Gal/Hr. Propane – 2.19 3

Orifice Drill Size 25 42

CFH 238.1 100.0

Gal/Hr. Propane – 2.74 3

CFH 285.7 120.0

Gal/Hr. Propane – 3.29 4

Orifice Drill Size 21 39

CFH 333.3 140.0

Gal/Hr. Propane – 3.84 5

Orifice Drill Size 23 41

CFH 381.0 160.0

PD 400 Gal/Hr. Propane – 4.38 6

➀ Above gases based on average standards. Units can be

furnished for gases of different values and specific gravities.

(Gal./Hr. based on 60°F. 30" Hg., 91,500 BTU/Gal.) In Canada,

refer to rating plate on side of unit for orifices at high altitude.

START-UP PROCEDURE

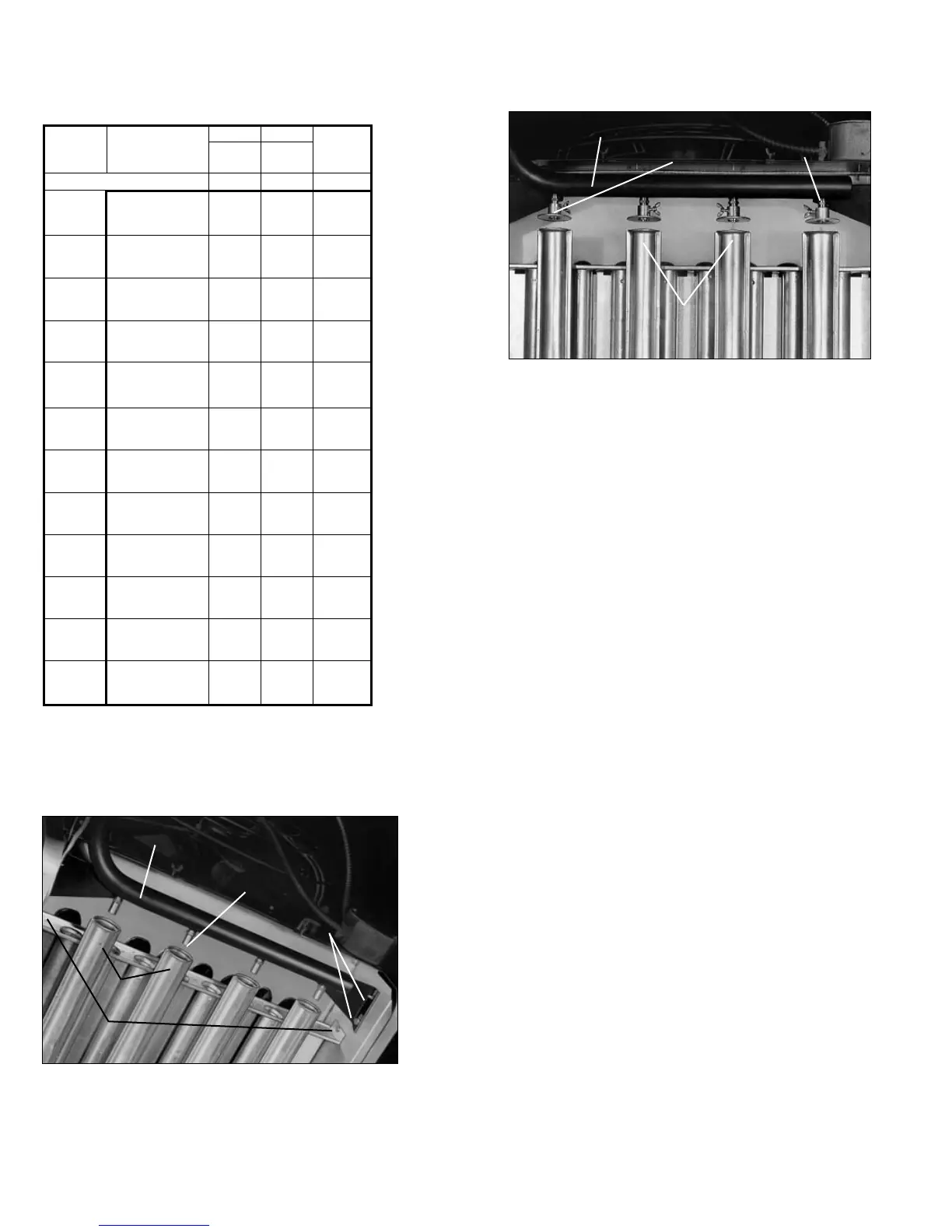

Figure 13.1

Manifold Adjustment, Natural Gas

MANIFOLD

MIXER

TUBES

BURNER

RETAINING PIN

MAIN

BURNER

ORIFICES

MANIFOLD MOUNTING

SCREW AND PIN

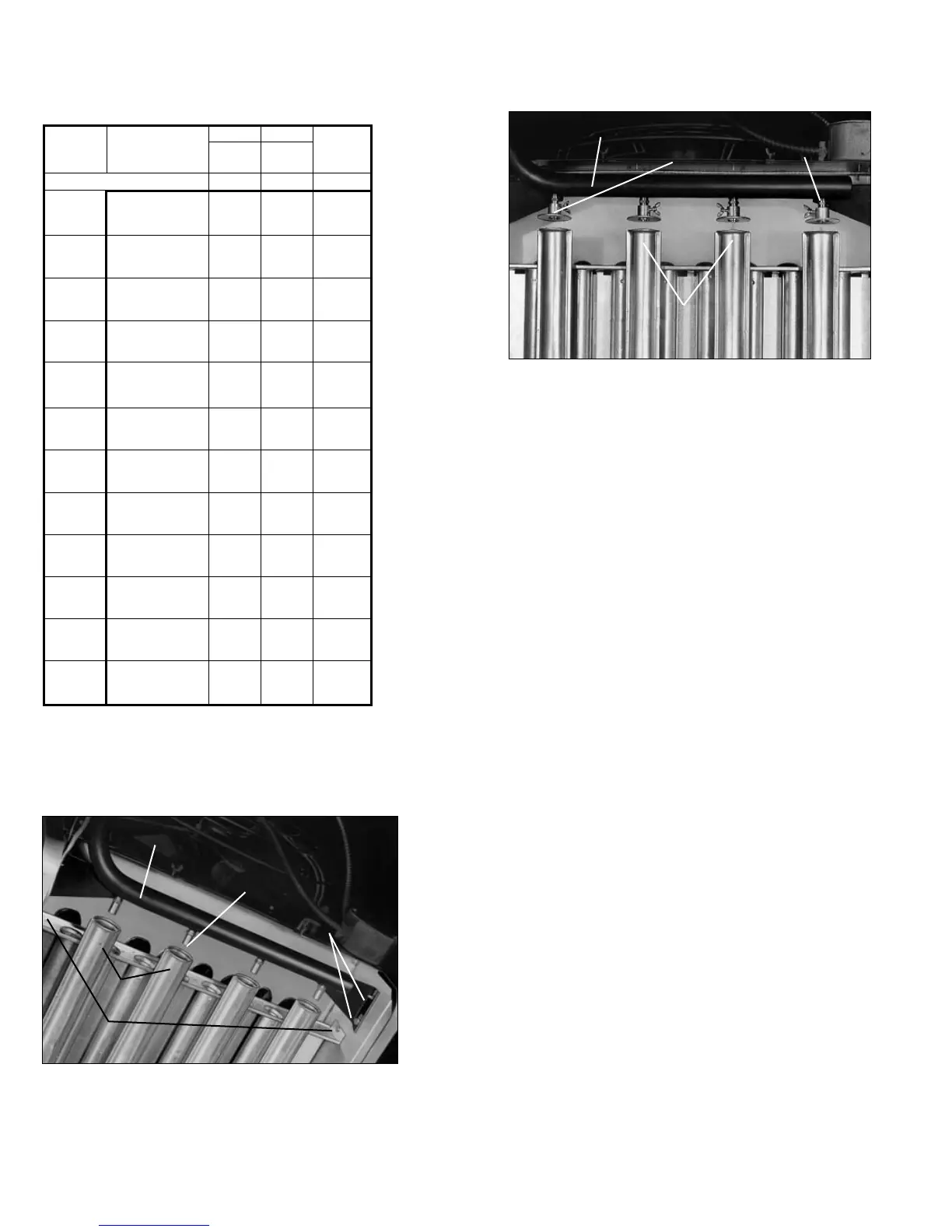

Figure 13.2 - Air Shutter Adjustment, Propane Gas

MANIFOLD

MIXER

TUBES

MAIN

BURNER

ORIFICES

AIR

SHUTTER

PD 50

BD 50

PD 75

BD 75

PD 100

BD 100

PD 125

BD 125

PD 150

BD 150

PD 175

BD 175

PD 200

BD 200

PD 250

BD 250

PD 300

BD 300

PD 350

BD 350

Loading...

Loading...