4

UNIT LOCATION

Sound and Vibration Levels

All standard mechanical equipment generates some sound and

vibration that may require attenuation. Libraries, private offices and

hospital facilities will require more attenuation, and in such cases,

an acoustical consultant may be retained to assist in the

application. Locating the equipment away from the critical area is

desirable within ducting limitations. Generally, a unit should be

located within 15 feet of a primary support beam. Smaller

deflections typically result in reduced vibration and noise

transmission.

UNIT LIFTING

All standard units are shipped fully boxed. Larger units are also

supplied with skid supports on the bottom of the box. The larger

units may be lifted from the bottom by means of a fork lift or other

lifting device only if the shipping support skids are left in place and

the forks support the whole depth of the unit. If the unit must be

lifted from the bottom for final installation without the carton in

place, be sure to properly support the unit over its entire length

and width to prevent damage. When lifting units, make sure the

load is balanced.

UNIT SUSPENSION

Be sure the method of unit suspension is adequate to support the

weight of the unit (see Weights for base unit and factory installed

option weights). For proper operation, the unit must be installed in

a level horizontal position. Combustible material and service

clearances as specified in Figure 3.1 and Tables 3.2 and 3.3 must

be strictly maintained. To assure that flames are directed into the

center of the heat exchanger tubes, the unit must be level in a

horizontal position. Use a spirit level to ensure that the unit is

suspended correctly.

The most common method of suspending Modine gas unit heaters

is to utilize 3/8” threaded rod. On each piece of threaded rod used,

screw a nut a distance of about one inch onto the end of the

threaded rods that will be screwed into the unit heater. Then place

a washer over the end of the threaded rod and screw the threaded

rod into the unit heater weld nuts on the top of the heater at least

5 turns, and no more than 10 turns. Tighten the nut first installed

onto the threaded rod to prevent the rod from turning. Drill holes

into a steel channel or angle iron at the same centerline

dimensions as the heater that is being installed. The steel channels

or angle iron pieces need to span and be fastened to appropriate

structural members. Cut the threaded rods to the preferred length,

place them through the holes in the steel channel or angle iron

and secure with washers and lock nuts or lock washers and nuts.

A double nut arrangement can be used here instead of at the

unit heater (a double nut can be used both places but is not

necessary). Do not install standard unit heaters above the

maximum mounting height shown in tables 17.1 or 17.3.

On all propeller units, except sizes 350 and 400, two tapped holes

(3/8-16) are located in the top of the unit to receive threaded rods.

Units with two point suspension, sizes 30 through 300, incorporate

a level hanging feature. Depending on what options and

accessories are being used, the heater may not hang level as

received from the factory. Do not hang heaters with deflector hoods

until referring to the “installation manual for deflector hoods” and

making the recommended preliminary adjustments on the heater.

These preliminary adjustments need to be made with the heater

resting on the floor.

Propeller sizes 30 through 300 units without deflector hoods that

do not hang level after being installed, can be corrected in place.

Simply remove both outer side panels (screws to remove are on

back flange of side panel) and you will see the (adjustable)

mounting brackets (Fig. 4.1). Loosen the set screws holding the

mounting brackets in place and using a rubber mallet or something

similar, tap the heater into a position where the unit hangs level.

Re-tighten set screws and replace the outer side panels.

Propeller sizes 350 and 400 have four mounting holes. On all

blower units, except the 350 and 400, two tapped holes are

provided in the top of the unit and two holes in the blower support

bracket. The 350 and 400 have four tapped holes in the top of the

unit and two in the blower support bracket for mounting.

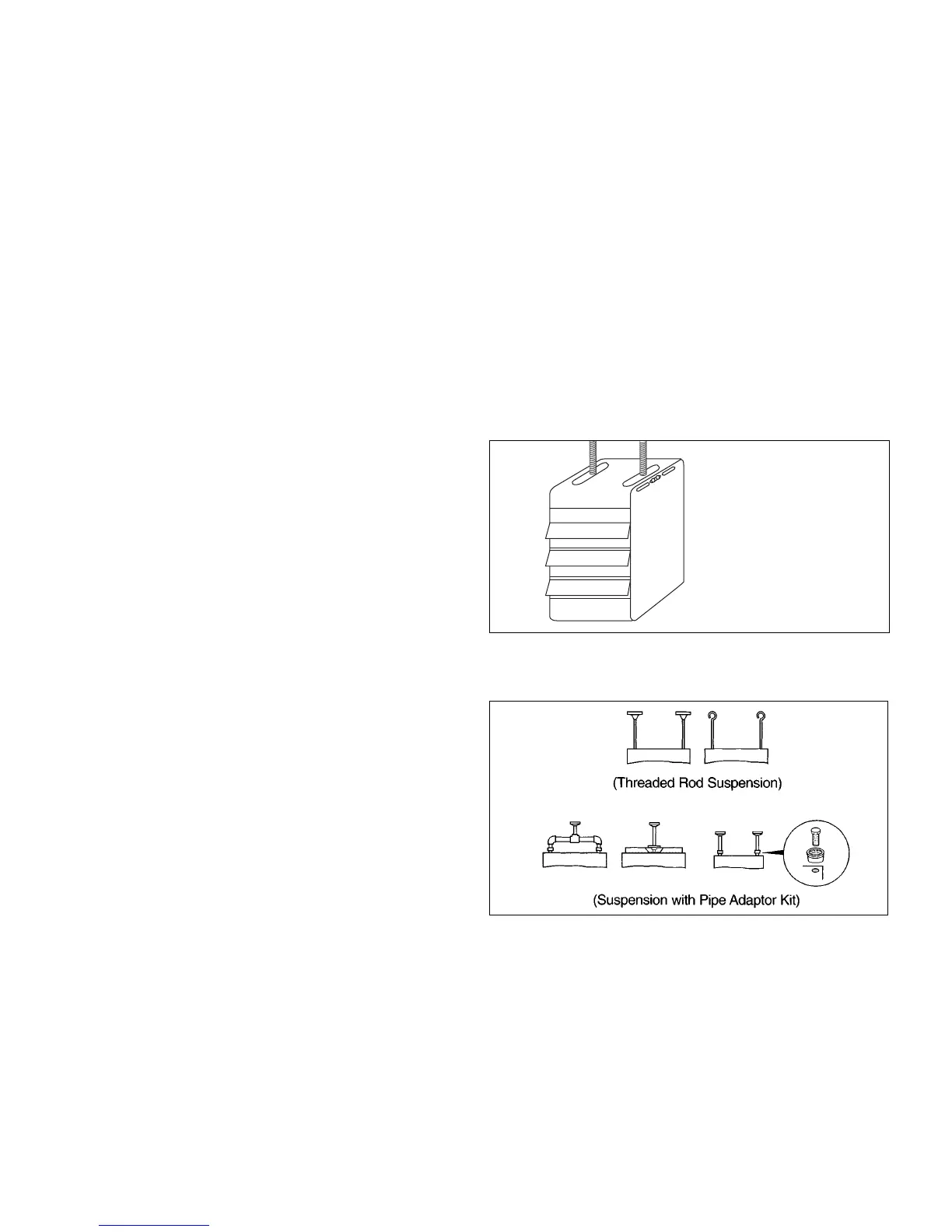

NOTE: A pipe hanger adapter kit, shown in Figure 4.2 is

available as an accessory. One kit consists of two drilled 3/4”

IPS pipe caps and two 3/8 - 13 x 1-3/4” capscrews to facilitate

threaded pipe suspension.

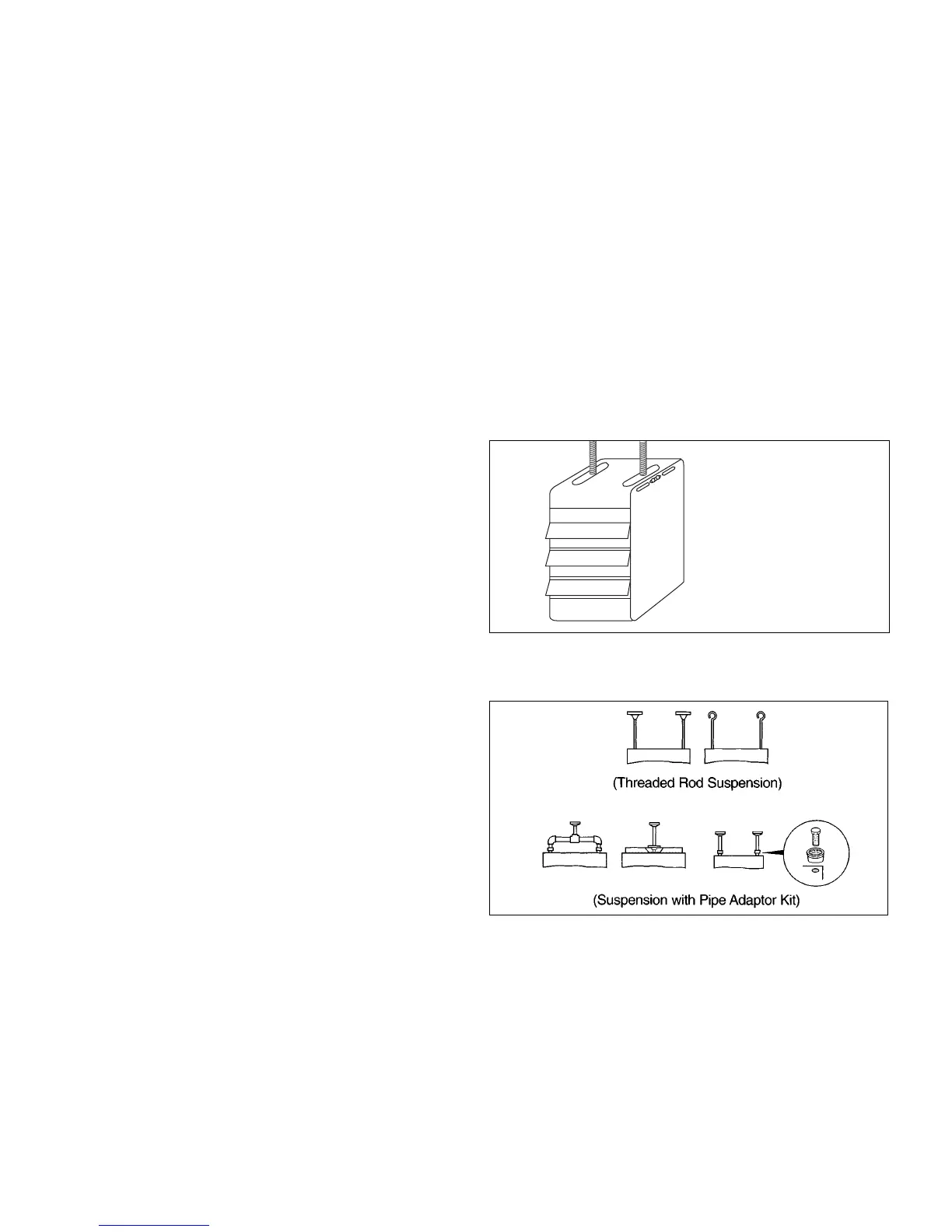

Figure 4.1

Adjustable Mounting Brackets - To Adjust:

Figure 4.2

Suspension Methods

1. Remove outer side panels.

2. “Set screws” - loosen and

position bracket where needed

– then tighten set screws.

3. Re-attach outer side panels.

Loading...

Loading...