4.3 Threshold optimisation 23

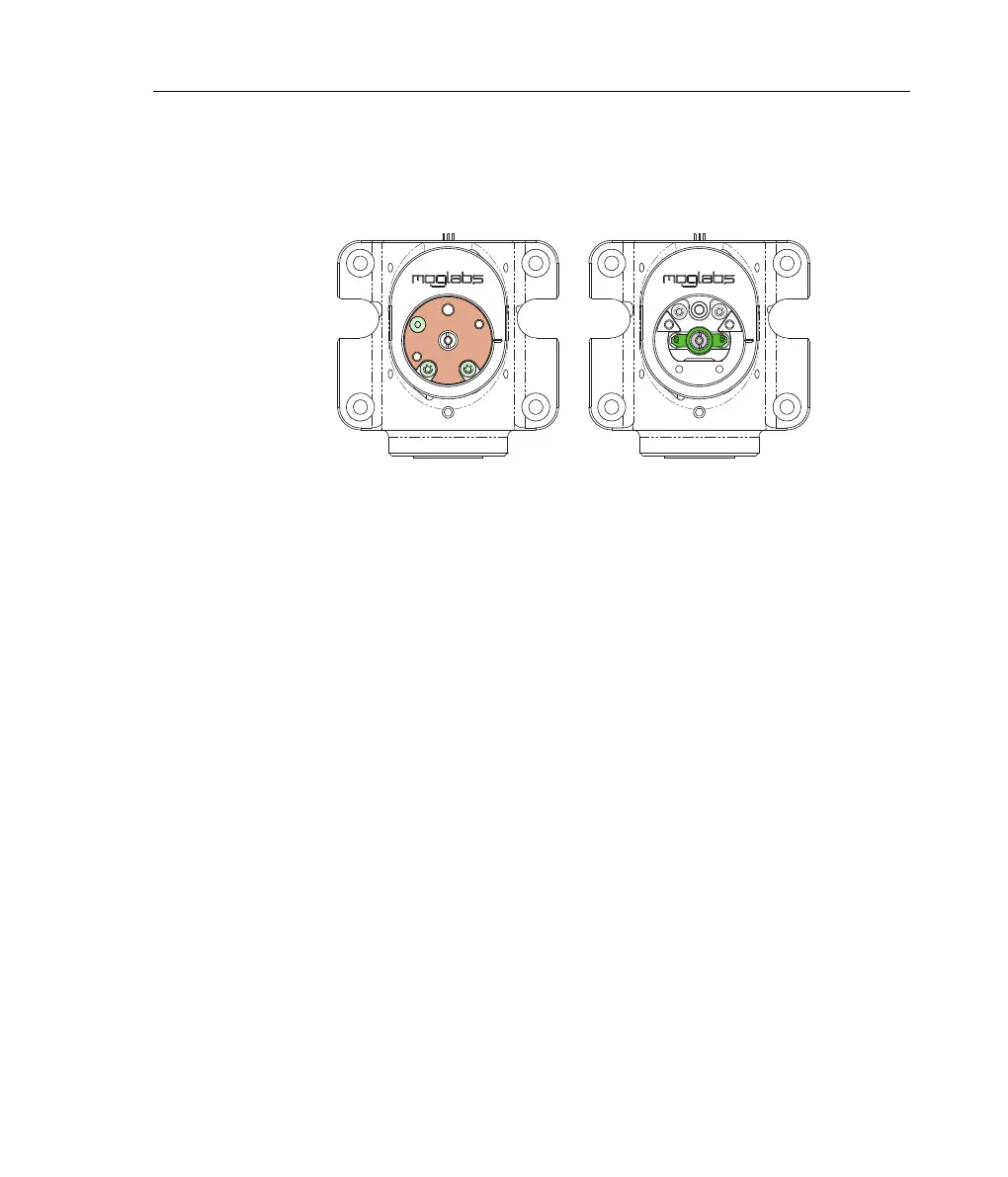

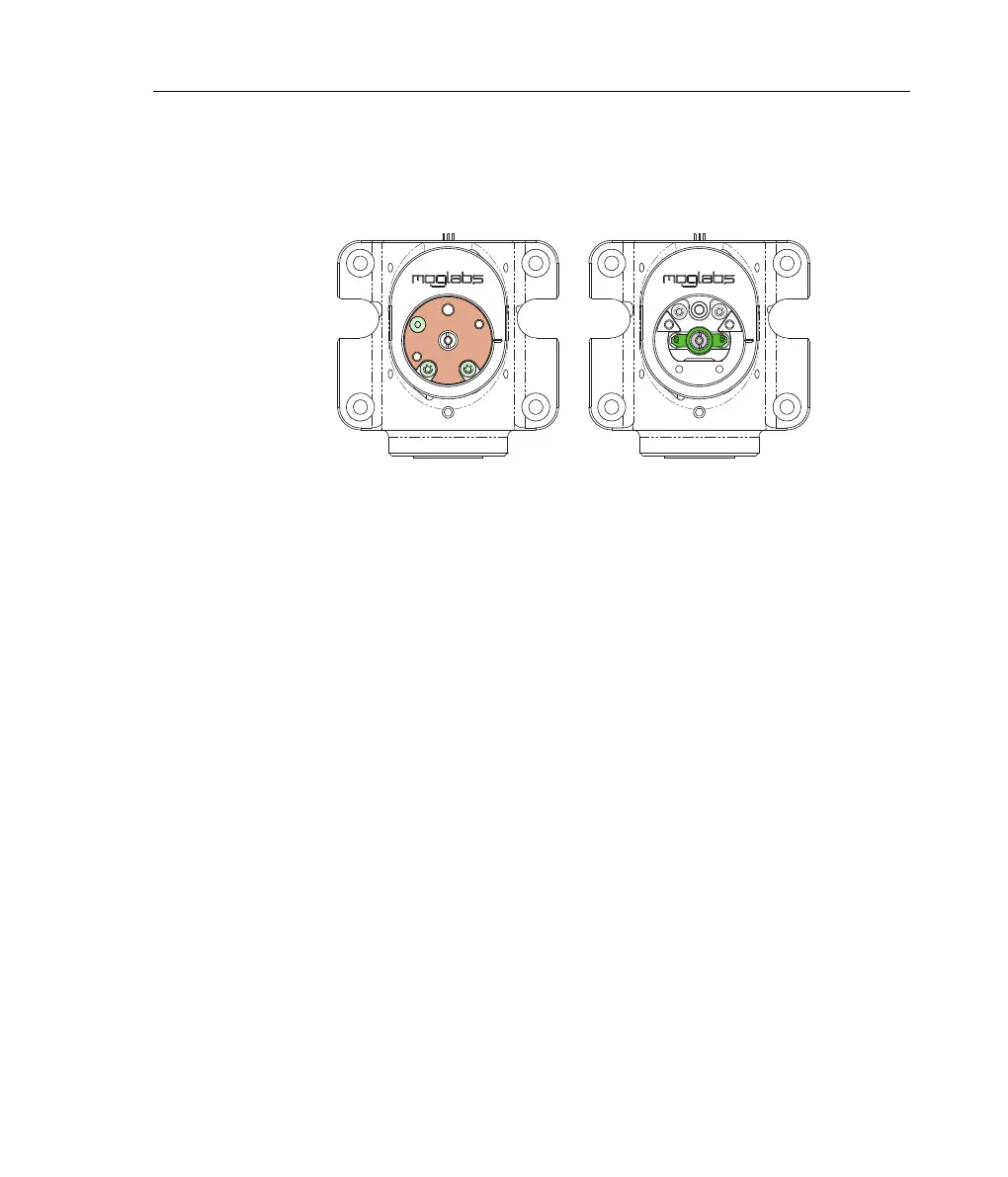

4. Removethebrassclampfromthecentralspindle,thenremovethe

threehexdrivescrewsholdingthecircularplateontopofthespindle

(see figure 4.2).

Figure 4.2: Removingtheintracavityfilterassembly. a)Threescrewsholdthe

top plate (pink)over the spindle.b) Spindle (green) must be alignedas pictured

before removal.

5. Rotatethefilterspindlesuchthatthefilteralignmentmark(themark

on the spindle, not the mark on the brass clamp) is aligned parallel

with the optical axis.

6. Gentlyprisethefilterassemblyfromthelaserbarrel(seefigure4.2).

If the filter seems stuck, it may be caught on the cateye output

couplerorlaserdiodetubesormayberotatedfromtherequired

orientation (see previous step).

7. Turnthe DLCon andadjustCURRENTto 5–10mAabovethethresh-

old specifiedin thelaser testreport.You shouldhave atleast 1mW

ofoutputpower,otherwiseincreasethecurrentfurther,butdonot

exceed the maximum safe current specified in the laser test report.

8. Monitor the laseroutput powerusing a powermeter asclose tothe

cateyeassemblyaspossible,thatis, beforetheisolator,withthe

powersensorangledslightlyfromorthogonaltotheopticalaxisto

protect the laser from back reflections from the sensor surface.

9. Adjust the cateye lens focus by rotating the threaded lens mount of

Loading...

Loading...