Page 4

TMC-647-(Rev E) - 01/06

MOORE FANS LLC, Marceline, MO 64658 Phone (660 ) 376-3575 FAX (660) 376-2909

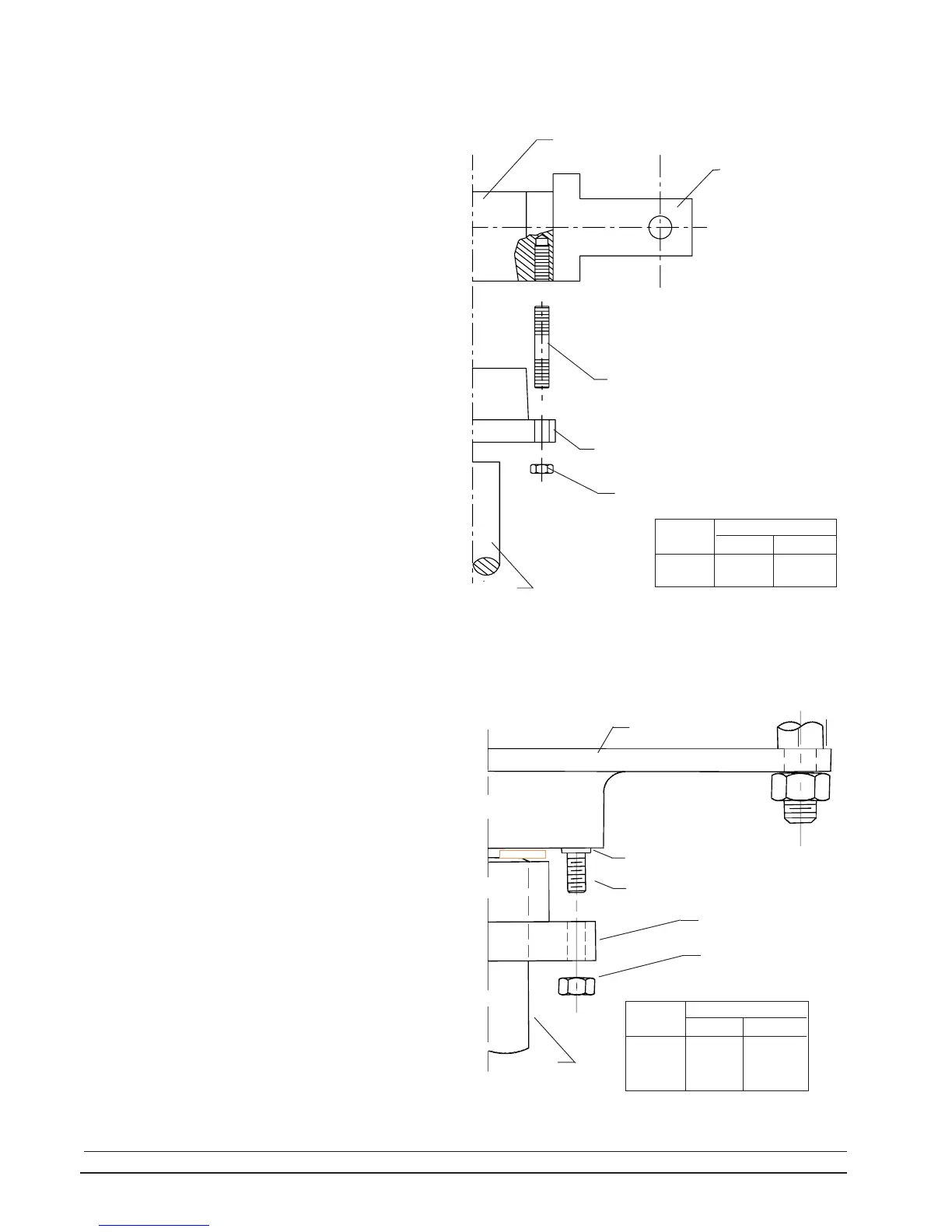

2.2.4 FOR AUTOMATIC HUBS

FAN HUB

SHAFT

STAINLESS NUT

(Specially Coated)

Q D BUSHING

STAINLESS STEEL BUSH-

ING STUD

BUSHING STUD WASHER

STAINLESS NUT (Specially Coated)

Q D BUSHING

STAINLESS STEEL BUSHING

STUD

MAXIMUM TORQUE

FT-LBS

20

M-KGS

2.77

BUSHING

SIZE

SF

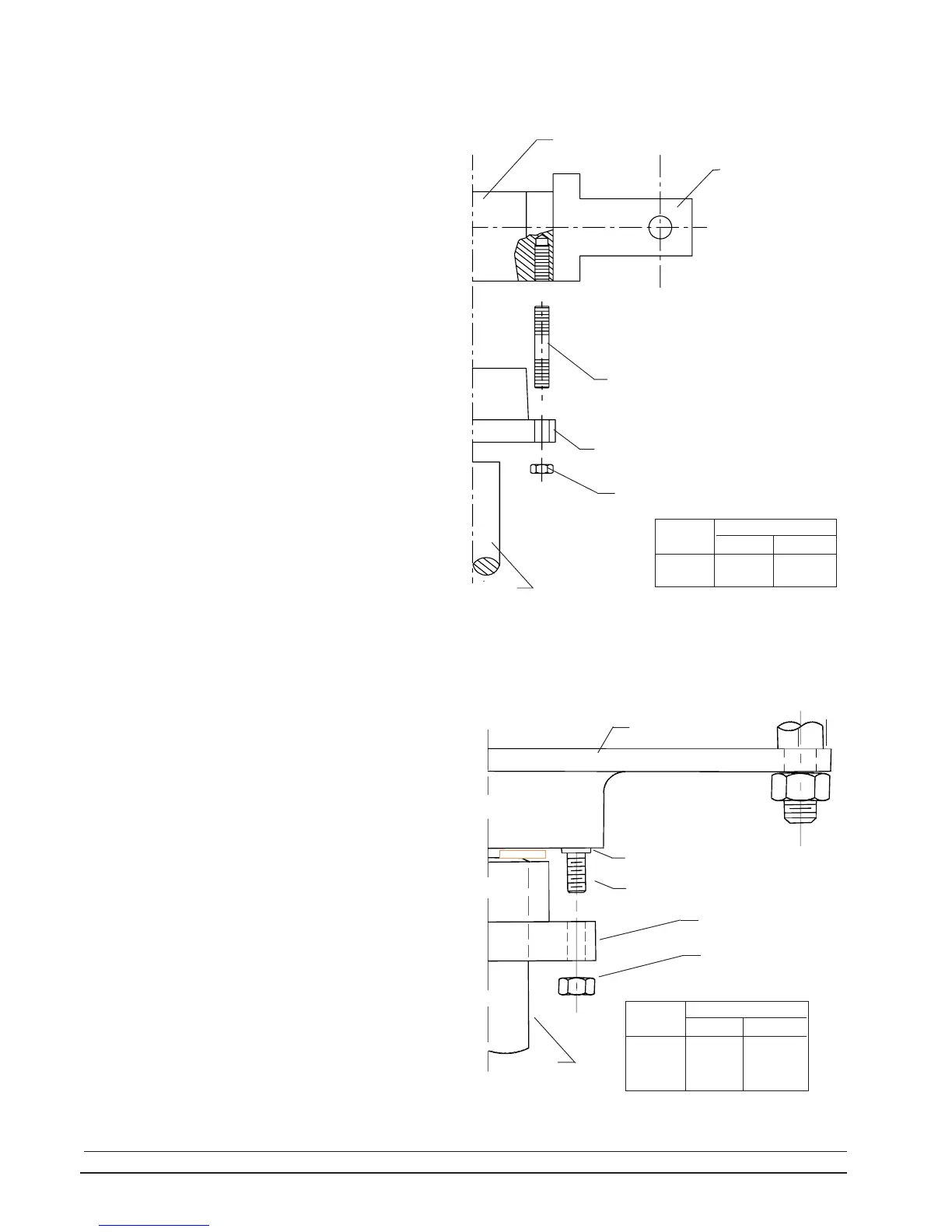

SHAFT

FAN HUB

BLADE CLEVIS

All Series 19 fans are manual tapered-bore hubs for

installation on Size SF QD bushings. They differ from the

other series in two respects. Because of the small hub size, an

air seal is not provided and blade tubes are not required The

blade clevises are threaded directly onto the hub.

Install the (3) stainless steel bushing studs in the fan hub

and hand-tighten only.

Slip the bushing onto the shaft and check the key for

proper fit. Be sure the shaft is completely through the bush-

ing.

Carefully clean the bore of the hub and the outside of the

bushing with a clean, dry cloth. Use no lubricants in this

installation. Use of lubricants can cause hub breakage.

Do not clean or alter the lubricant coating on the hex

nuts.

Install the fan hub on the bushing with the studs extend-

ing through the bushing flange. Place the stud nuts on the

studs and tighten the nuts alternately, keeping the pull on all

of them as nearly equal as possible while drawing the hub

onto the bushing until the bushing tightly grips the shaft.

Caution should be used to prevent the hub from cocking on

the bushing.

Tighten the nuts to the torque shown in the table at

right.. Do not over-torque. Excessive torque can cause hub

or bushing breakage.

MAXIMUM TORQUE

FT-LBS

20

40

90

BUSHING

SIZE

SF

E

J

M-KGS

2.77

5.53

12.44

If the (3) stainless steel bushing studs are not already

installed in the fan hub, install them at this time. Hand-tighten

only.

Slip the bushing onto the shaft and check the key for

proper fit. Be sure the shaft is completely through the bushing

but not extending beyond it. The end of the shaft should be

flush with the top of the bushing.

Carefully clean the bore of the hub and the outside of the

bushing with a clean, dry cloth. Use no lubricants in this

installation. Use of lubricants can cause hub breakage.

Do not clean or alter the lubricant coating on the hex

nuts.

Air seals are installed by the factory whenever crating

requirements permit. If the air seal is already installed, lift the

hub by grasping the hub tubes or clevises. Do not lift the hub

by the air seal.

Lower the hub onto the bushing with the (3) stainless

steel studs provided in the hub extending through the bush-

ing flange.

Place the stud nuts on the studs and tighten the nuts

alternately, keeping the pull on all of them as nearly equal as

possible while drawing the hub onto the bushing until the

bushing tightly grips the shaft. Caution should be used to

prevent the hub from cocking on the bushing.

Tighten the nuts to the torque shown in the table at right.

Do not over-torque. Excessive torque can cause hub or

bushing breakage.

2.2.3 FOR SERIES 19 HUBS ONLY

INSTALLATION

Loading...

Loading...