Page 8

TMC-647-(Rev E) - 01/06

MOORE FANS LLC, Marceline, MO 64658 Phone (660 ) 376-3575 FAX (660) 376-2909

2.5.3 ADJUST BLADE ANGLE (EXCEPT SERIES 19)

Hubs are shipped from the factory with the clevises set

for the blade angle indicated by the design performance. A

change in blade angle is usually necessary, however, to

adjust to actual site conditions. Failure to adjust the blade

angle when required may result in motor overload. To check,

measure the input amps to the motor while the fan is oper-

ating. See Section 2.6 Start-up Procedures below. If the

current draw is higher or lower than desired, slightly de-

crease or increase the blade angle.

blade rotated to one of these two positions.

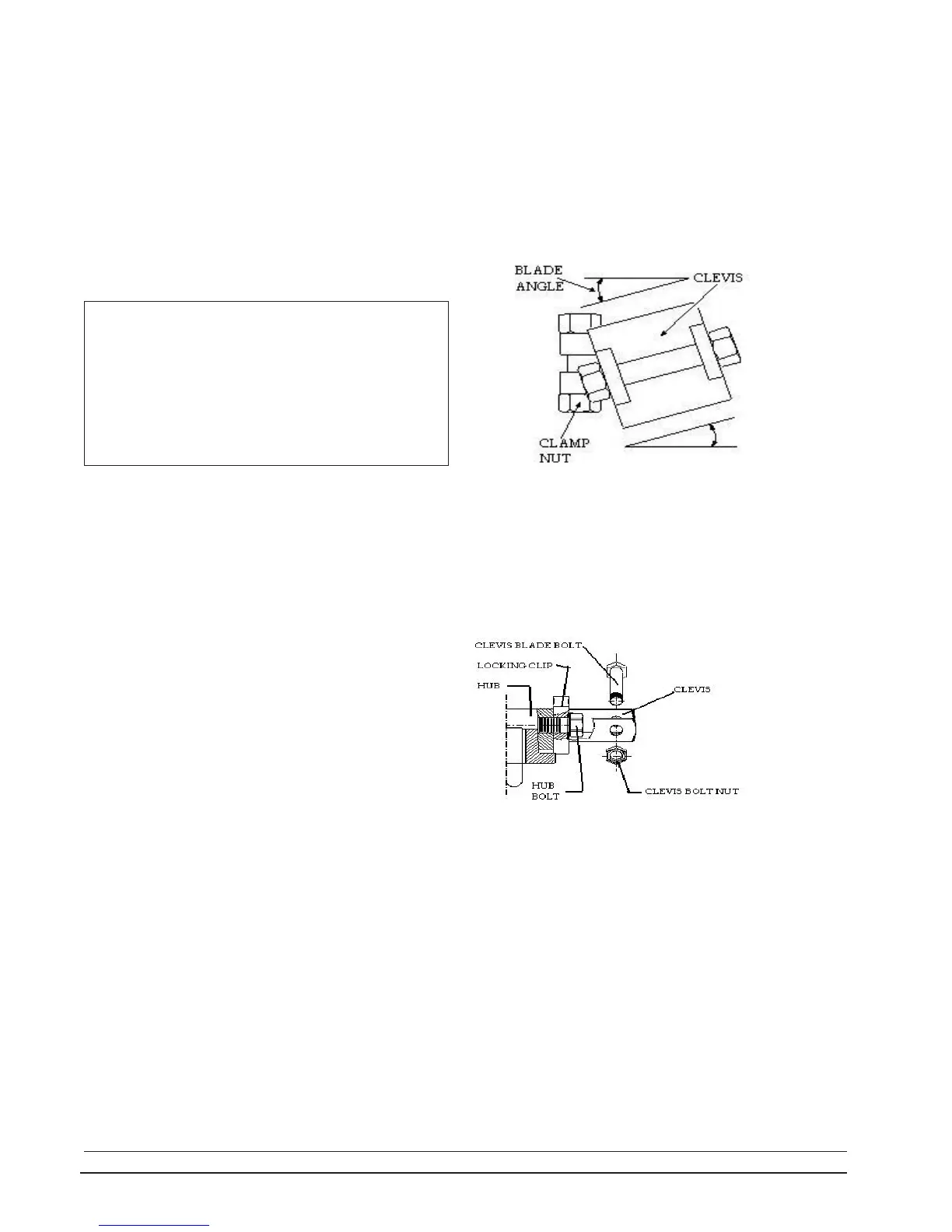

Place a protractor level on the flat upper or lower

surface of the clevis as shown in the illustration at right. (This

is the point of measurement of the blade angle stated on 1.1

Fan Specifications.) Make a permanent record of the final

NOTE: If the hub is not level, the blade angles will not

be accurately measured. To check, rotate the fan while

checking the angle of a blade. If the measured angle varies

as the fan is rotated, find the two locations, 180

o

apart, where

the angles are identical. Only at these two points will the

angle measured be accurate. Set each blade angle with the

WARNING: The fan is designed to consume the

horsepower stated on the Fan Specification Sheet. This is

not necessarily the full load horsepower of the motor.

Increasing the blade angle to fully load an oversize motor

can cause serious blade overload which will stall the

blades. In this condition, the fan will actually deliver less

air and blade life may be shortened. Blade load consider-

ations are discussed in Section 4.0 Operation in this manual.

2.5.4 ADJUST SERIES 19 BLADE ANGLE

Before starting the fan, manually check all bolts or

nuts to see if they are tightened. Take care not to exceed

the stated torque limits.

Lift each blade to the horizontal position and walk

the blade around while checking for proper clearance.

Start the fan and watch it in operation. All blades

should lift to the same operating position, indicating that

the blade angles are properly set and that all blades are

equally loaded.

If vibration or unbalance is evident, see Section 3.3 in

the following maintenance section.

After the fan has been operating for several minutes,

stop the fan and observe the blades as the fan comes to

rest. All of the blades should fall to their droop position at

the same rate.

Inspect the inner surface of the fan ring and the blade

tips for any indication of scoring.

Check the motor amperage and consult the motor

manufacturer's specification sheet for the actual motor out-

put horsepower for that amperage. The HP given on the

Fan Specifications is the calculated HP (at the fan shaft) that

is required for the specified performance. The motor output

HP may be allowed to be 3% or 5% above the specified fan

HP to allow for gear drive or belt drive losses respectively.

Consult the factory or the fan curve before increasing

the blade angle for the fan to consume more than the speci-

fied HP.

2.6 START-UP PROCEDURES

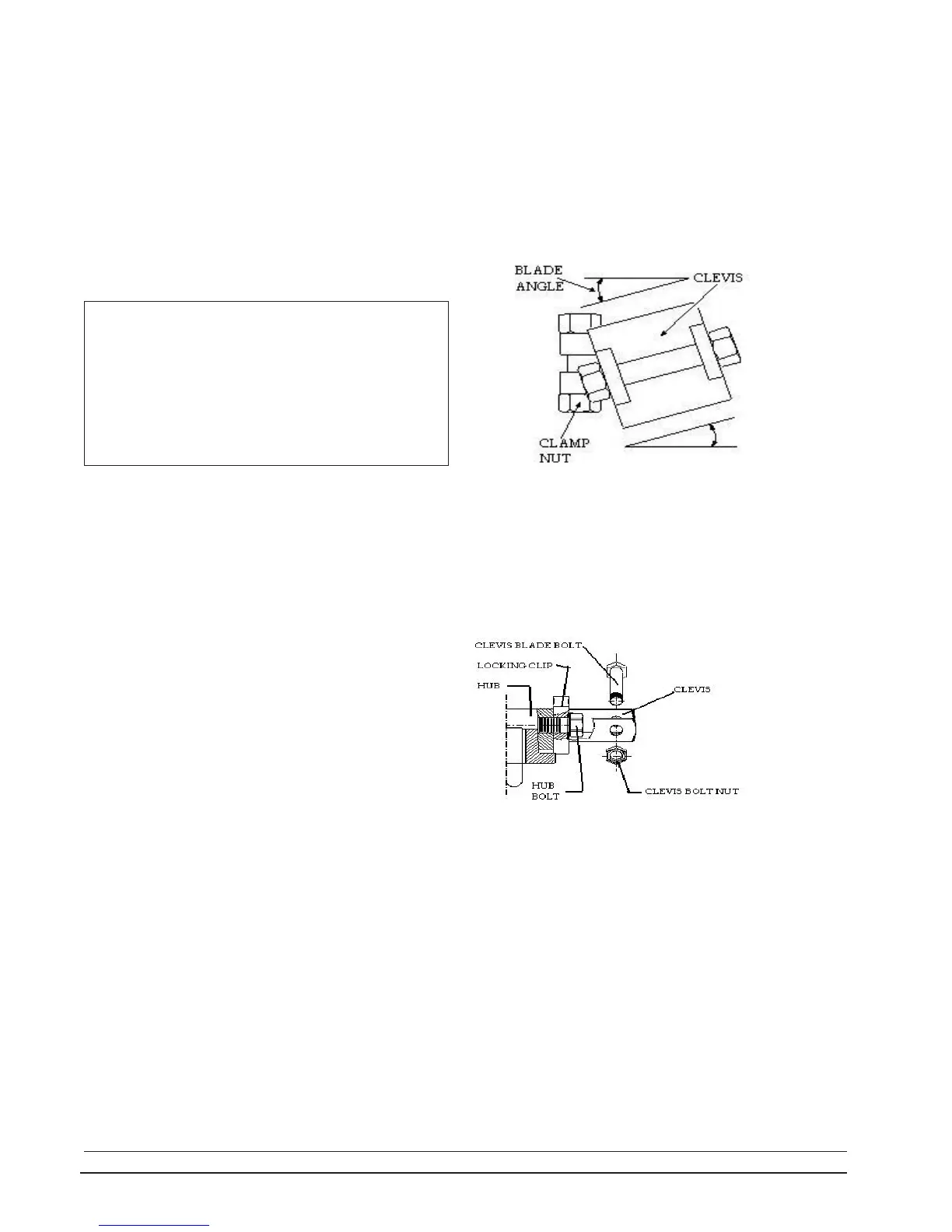

Read the previous Section 2.5.3 and follow all the

precautions stated. To adjust, remove the blade. Flatten

the tab on the locking clip and loosen the hub bolt just

enough to allow the clevis to be turned. Place a protractor

level on the flat upper side of the clevis and rotate the

clevis in the desired direction. Retighten the hub bolt to 90

to 100 ft-lb (12.5 to 13.8 m-kg) of torque. Recheck the angle

after tightening. Bend one corner of the locking tab against

a flat side of the bolt head to secure the bolt from turning.

Operate the fan and recheck the current draw. Repeat ad-

justment if necessary until amperage readings are as de-

sired.

INSTALLATION

clevis angle selected and take care that all blades on the fan are

set at the same angle. A typical adjustment may be +/- 3

o

.

The maximum recommended clevis angle is 18

o

. For all fans

except Series 19, the blade angle is changed by loosening the

clamp nut, rotating the clevis, and retightening as described

in 2.5.2 above. Torque all clamp nuts to 50 ft-lb (7 m-kg).

Loading...

Loading...