Page 6

TMC-647-(Rev E) - 01/06

MOORE FANS LLC, Marceline, MO 64658 Phone (660 ) 376-3575 FAX (660) 376-2909

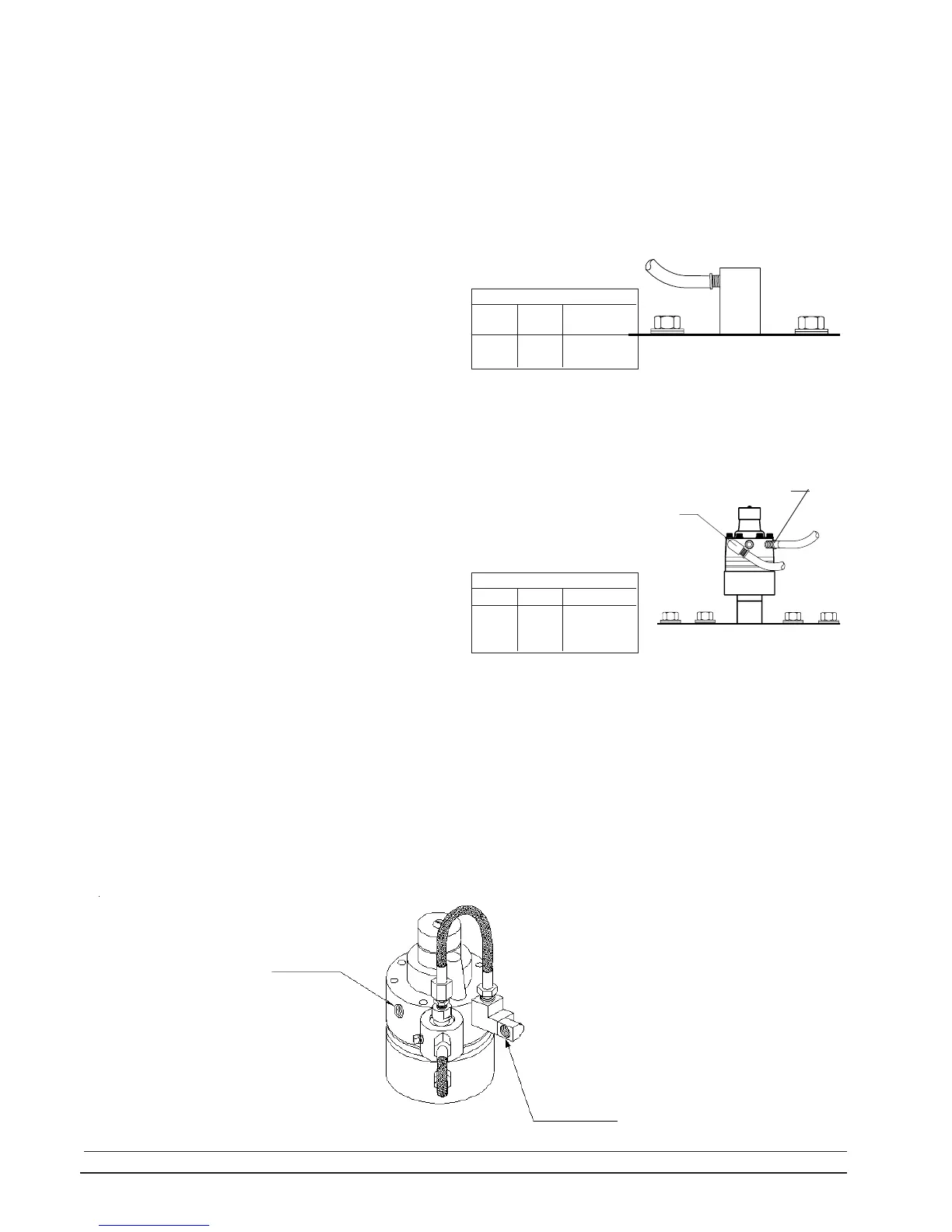

2.4.2 FOR AUTOMATIC HUB WITH STANDARD POSITIONER

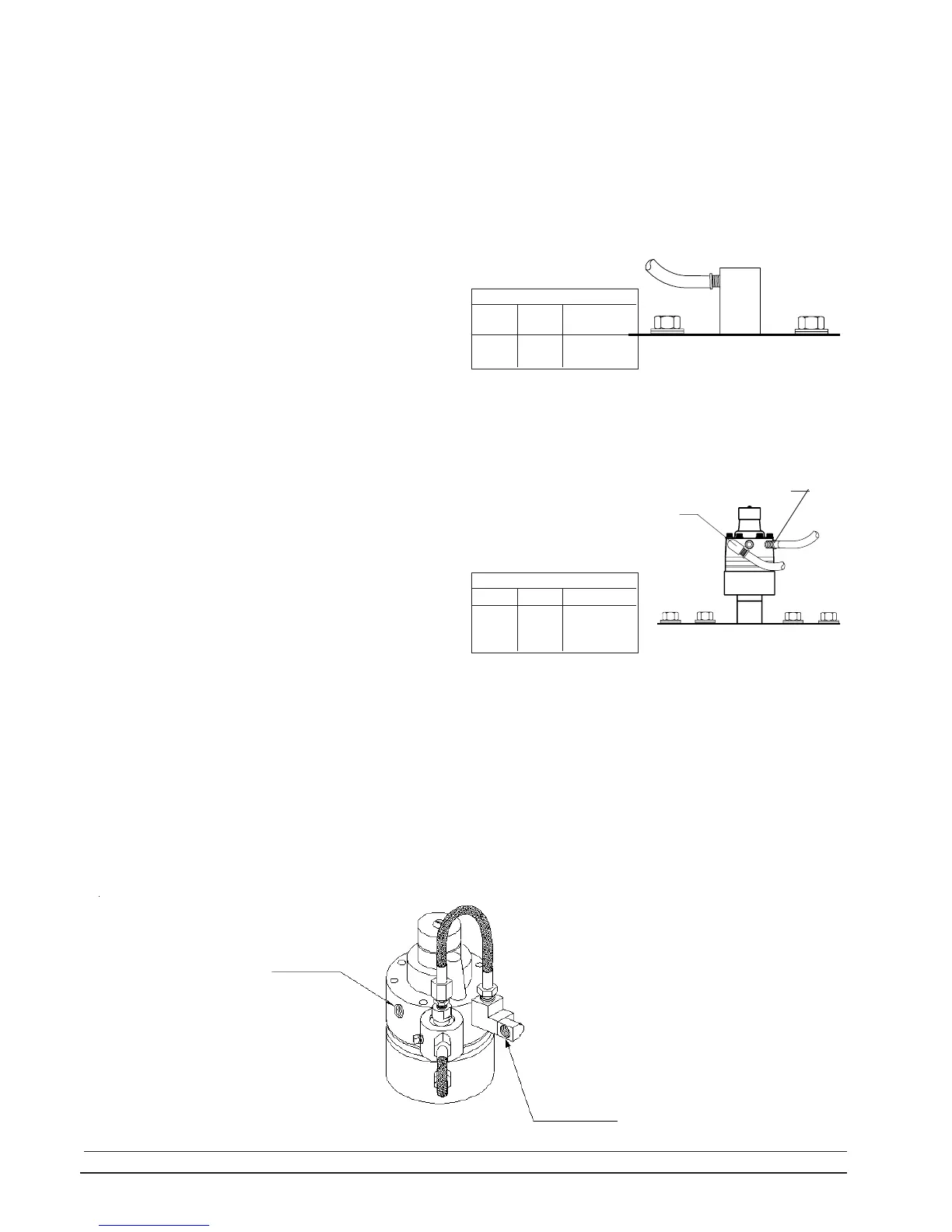

2.4.3 FOR POSITIONER WITH FAIL LOCKED IN LAST POSITION

Flexible Hose

Installed on

Rotary Union

MAXIMUM SUPPLY PRESSURE:

60 P.S.I. (4.2 Kg/Cm

2

)

Pressure Requirements

Flexible Hoses

Connected to Supply

and Instrument Ports

on Positioner

MAXIMUM SUPPLY PRESSURE:

50 P.S.I. (3.5 Kg/Cm

2

)

0.21 to 1.54

0.42 to 2.24

No. of

Blades

P.S.I.

Kg/Cm

2

3 to 8

9 to 12

3 to 22

6 to 32

2.4.1 FOR AUTOMATIC HUB WITHOUT POSITIONER

Kg/Cm

2

P.S.I.

Control

Supply

3 to 15

(Std)

55

0.21 to 1.05

(Std)

3.9

When a fan is specified to fail locked in last position,

pressure is retained in the actuator chamber if the system

pressure falls abruptly. This retained pressure prevents the

blade angle from changing when a failure occurs in the

system supply pressure.

Connect hoses "A" to the instrument port as described

in 2.4.2. Hose "B", which is normally connected to the supply

port is to be connected to the fitting labeled "source air

supply". The flexible hoses provided must be used and a little

slack must be left in them to prevent damage to the bearing or

seal in the rotary union.

When the system is charged, normal pressure at the

valve keeps it in the open position and flow occurs in either

direction between the positioner and the supply actuator. If

the system pressure fails, the valve automatically closes,

retaining pressure in the actuator.

Connect the special flexible hoses provided to the

instrument port "A" and the supply port "B" shown in the

drawing. Use the elbow provided on one hose so that the

hoses will be parallel. Support the positioner while tighten-

ing all fittings to prevent rotary union damage.

The flexible hoses supplied must be used and a slight

amount of slack should be left when connecting to rigid

piping to relieve any abnormal loading of the rotary union

internal bearings and seal.

The ends of the hoses must be capped if not coupled to

the system piping immediately. The flexible hoses provided

terminate in 1/4" N.P.T. male fittings.

A

B

2.4 INSTALL PNEUMATIC TUBING

Connect the flexible hose provided to the rotary union

by threading into the opening. Support the rotary union

while tightening the hose fitting to prevent damage to the

rotary union. The flexible hose must be used. When coupling

to the plant piping, a small amount of slack should be left

to relieve any abnormal loading of the internal bearings

and seals.

If the fan has been specified to fail locked in last

position, the hose is connected to the remote valve piping

rather than directly to the system control pressure and will

function as described in 2.4.3 below.

The hose provided terminates in a 1/4" N.P.T. male

fitting.

INSTRUMENT INPUT

A

SOURCE AIR SUPPLY

INSTALLATION

Loading...

Loading...