MOORE FANS LLC, Marceline, MO 64658 Phone (660 ) 376-3575 FAX (660) 376-2909

Page 17

TMC-647-(Rev E) - 01/06

charge may be increased by as much as 45

degrees under

high wind conditions.

In forced draft air coolers where the fan is mounted

horizontally, blowing upward, and nearly always in a

very short ring, the condition is even more critical. In such

an installation, the air on the inlet side of the fan has a

horizontal velocity which may be quite high. It is neces-

sary for the fan to pick up this air and direct it upward. In

4.5.1 GENERAL

Any condition which causes repeated blade loading

and unloading is detrimental to fan performance, both in

terms of efficiency and structural durability. Normal ob-

structions, of course, must be expected in the air stream.

There are certain conditions, however, which may be

avoided by reasonable attention to the points briefly dis-

cussed in this section. Additional information on the

importance of inlet and discharge conditions can be found

in Moore's General Catalog.

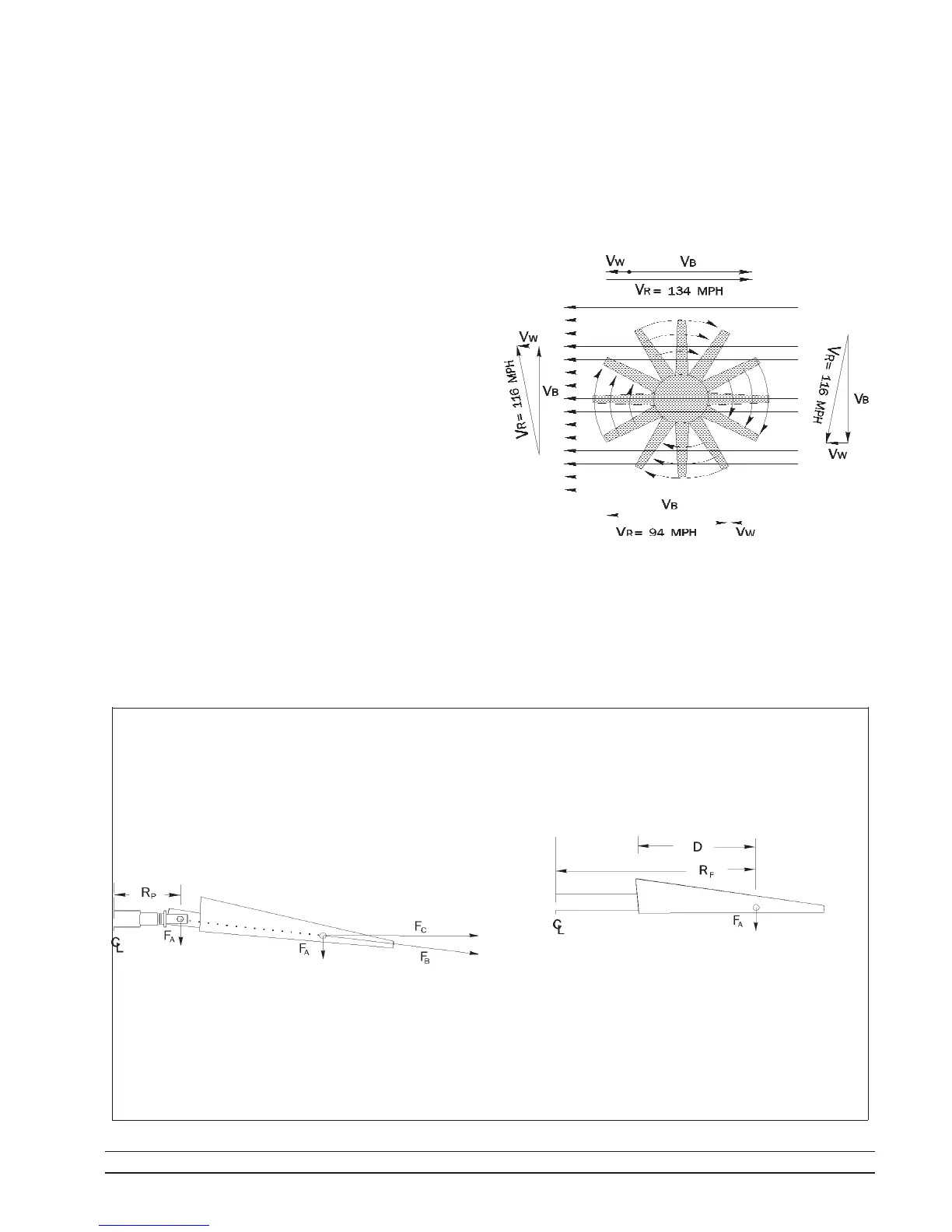

Ideally, air should approach a fan in an axial direc-

tion and at a uniform velocity over the area of the fan. Air

approaching a fan at an angle tends to increase the relative

velocity of the blades to the air on one side of the fan and

decrease the relative velocity on the other side. This means

that the fan blade during one-half of its revolution is

picking up a heavier air load due to the higher relative

velocity and, through the other half of its revolution, a

lower air load as it goes "down wind". The net result is a

repetitive loading and unloading of the blades at each

revolution of the fan. This condition can be quite serious if

the velocities are high and the angle of approach deviates

considerably from axial.

4.5.2 WIND

In an induced draft air cooler or cooling tower with

the fan mounted on top of the unit in a horizontal position,

blowing upward, and surrounded by a short fan ring or

stack, high winds may cause some concern. The higher

the ring extends above the fan, the less effect would be

expected from wind. It is a fact, however, that wind across

the top of the ring will affect the direction of air flow well

down into the ring. In the case of a fan installed near the

top of the ring, the direction from axial of the fan dis-

a strong wind, the angle of air moving through the fan

may be increased more than 45

degrees.

The illustration above assumes a fan operating with

a tip speed (VB) of 10,000 feet per minute (114 miles per

hour) with a horizontal component of wind velocity (VW)

of 20 miles per hour. Note that the velocity (VR) of the fan

blade relative to the air varies by a factor of 1.43. The

blade load varies as the square of this velocity, or 2.05.

4.5 DAMAGING OPERATING CONDITIONS

OPERATION

THE EFFECT OF AIR LOAD ON HUB AND DRIVE

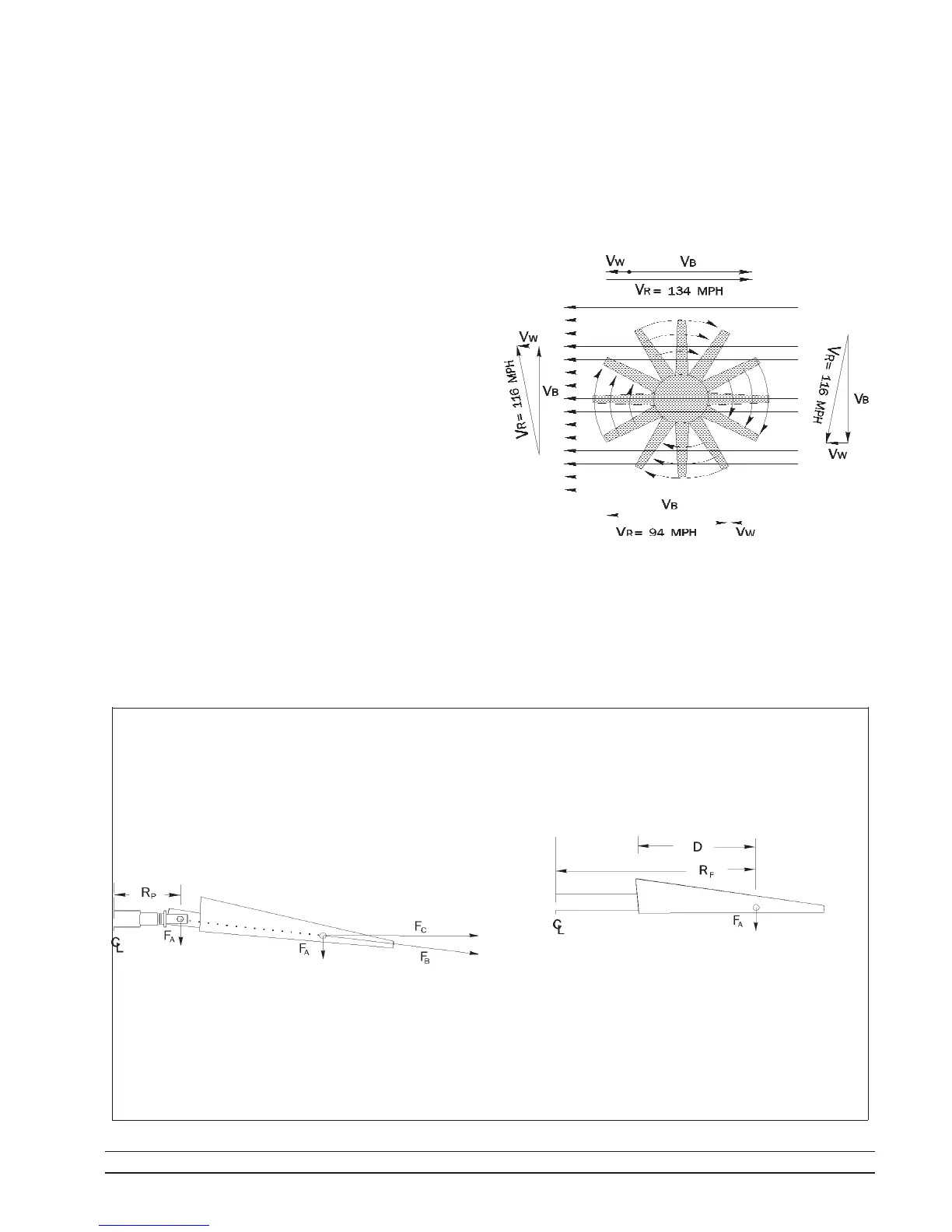

Moore fan blades are attached to the hub by a pivot.

As the fan rotates, centrifugal force causes the blades to

rise (as do the blades of a helicopter). The air load (FA) is

uniform over the blade, but there is a point (shown on the

blade in the drawing below) where, if the total load were

applied at that point, the effect would be the same. The

resultant of the air load (FA), assumed in this example to

be downward, and the horizontal centrifugal force (FC) is

the force on the blade (FB). The blade automatically posi-

the bending moment at the shaft due to the air load is

equal to the load (FA) multiplied by the distance from the

fan centerline to the point of application of the force on

the blade (RF). This moment will be from 2 to 4 times as

great as that produced by the Moore fan under the same

conditions.

Also of concern with the conventional fan is the

bending moment due to the air load at the point of

attachment of the blades to the hub since this is usually

the structurally weakest area of the fan. The moment due

to the air load at this point is the load (FA) times the

distance (D). For the Moore fan, this moment is zero since

the blades are attached at the pivot point.

A more complete discussion of the Moore fan de-

sign can be found in Moore’s General Catalog.

tions itself in the direction of this force with the result that

the force is translated inward to the pivot point, as illus-

trated by the dotted line. The effect of this arrangement is

exactly as if the total air load (FA) were applied at the pivot

point rather than at the point outward on the blade. The

maximum bending moment applied to the shaft by the air

load is equal to the load (FA) multiplied by the distance

from the fan centerline to the pivot point (RP).

In conventional fans with rigidly attached blades,

Loading...

Loading...