Corporate Headquarters: 1080 North 11th Street, San Jose, CA 95112 Phone: (408) 292-2214 Fax: (408) 292-2733

www.etorque.com

Page 26

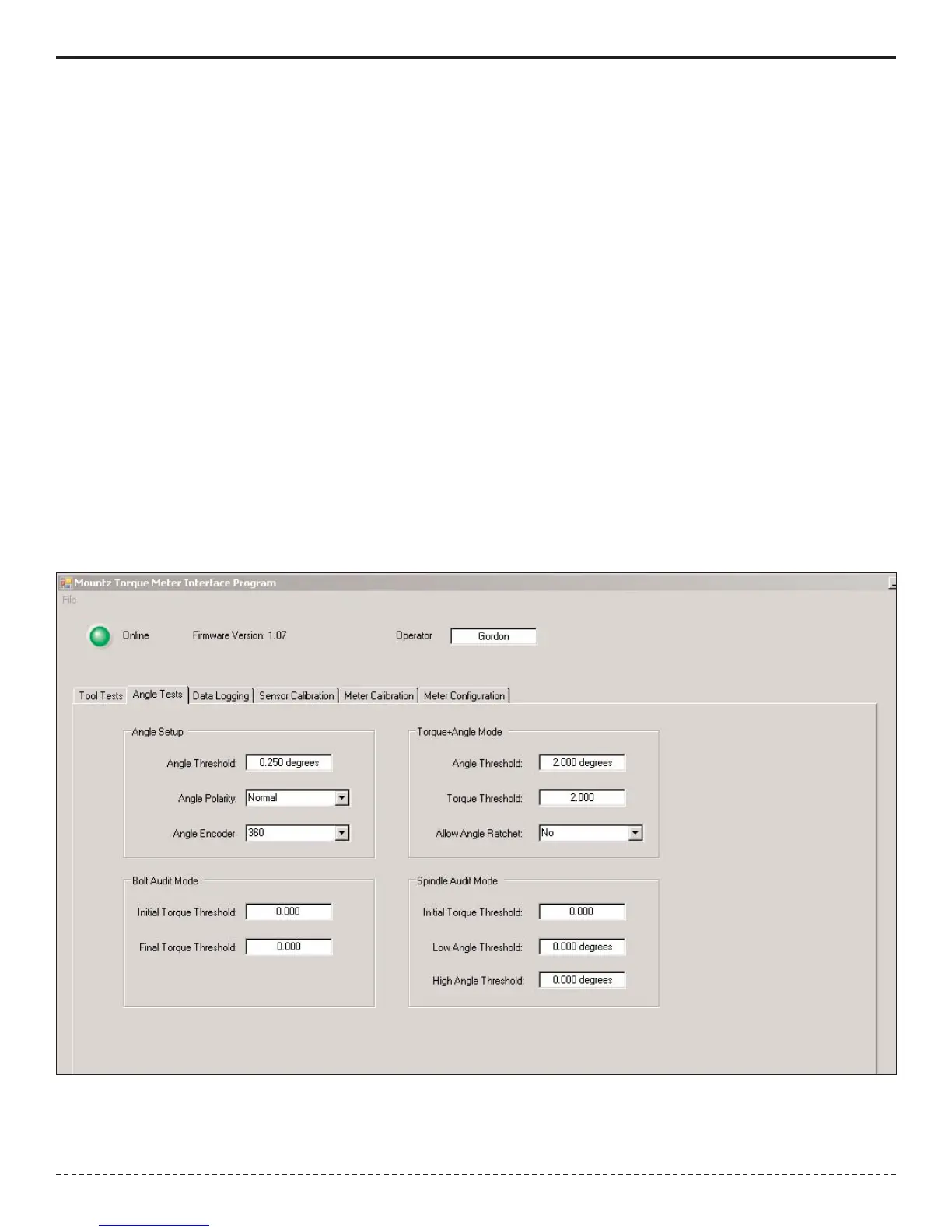

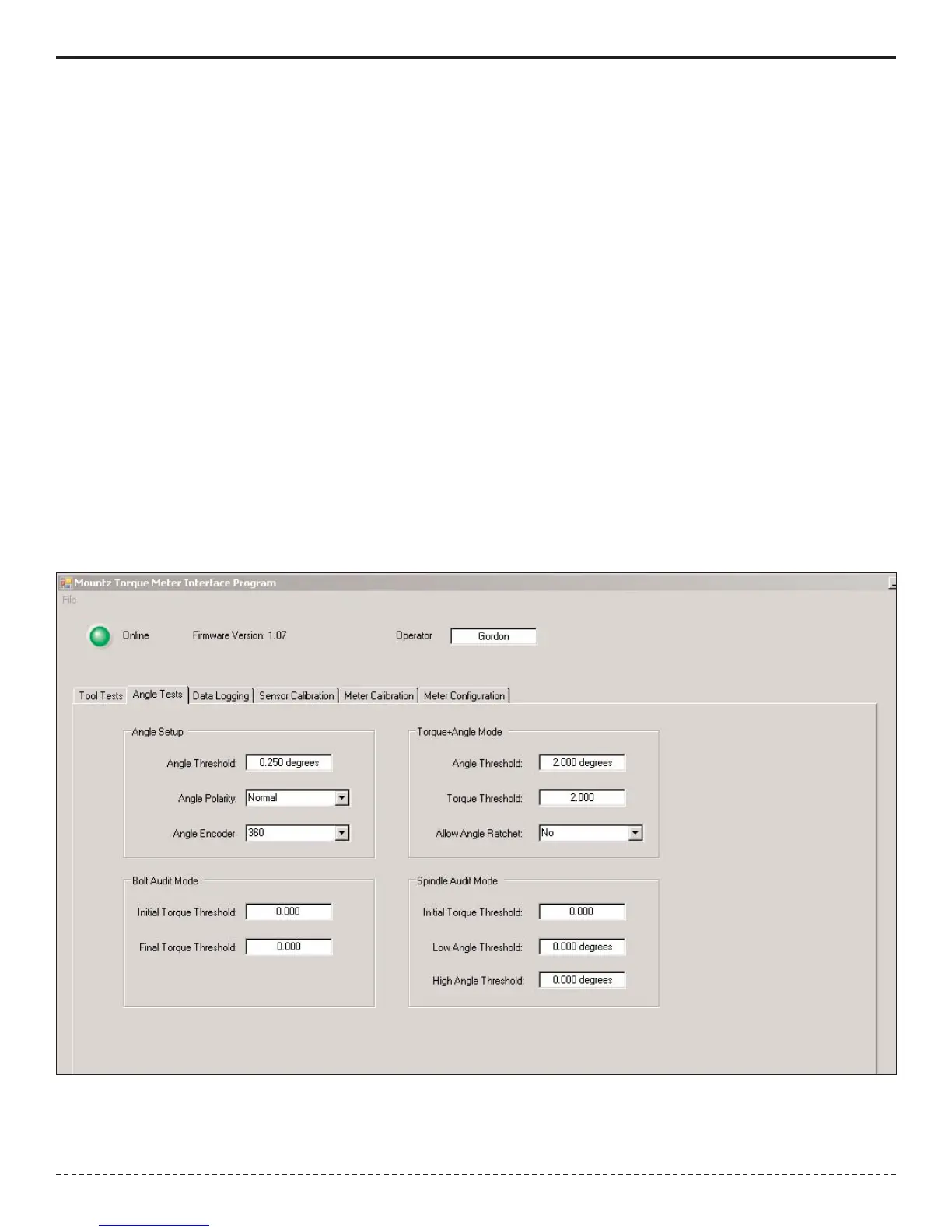

The purpose of the bolt audit function is to report the degree of movement from the initial torque threshold to the final

torque threshold. The torque analyzer will display the final torque threshold and the total angle displacement, which has

occurred from the initial torque threshold and final torque threshold.

Spindle Audit Explanation

1. Spindle Free Test:

The operator turns on the tightening spindle and the spindle starts rotation, the PTT begins to count angle immediately,

and when the spindle stops, the PTT will display and record the final angle, and final peak torque. Set up the initial

values. The Initial Torque should be entered as zero so that the Angle will begin to be counted as soon as the spindle

starts moving.

2. Spindle within required tolerance:

Set up the initial values such as the Initial Torque, the Low Angle Threshold and the High Angle Threshold. An example

would be a Torque of 15 N.m, Low Angle Threshold of 40 degrees and a High Angle Threshold of 50 degrees.

When the tightening spindle reaches 15 N.m, the Angle begins to be counted. If the spindle stops between 40-50

degrees, the LED shows green, and the display shows the final Angle and the final Torque.

If the spindle stops before reaching 40 degrees the LED will show red and the display shows the final result.

If the spindle stops after exceeding 50 degrees the LED will show red and the display shows the final result.

Loading...

Loading...